Affordable and Quality Chopper Blade Prices on the Rise

By:Admin

The chopper blades, which are an essential component of helicopters and other rotary-wing aircraft, are manufactured using advanced technology and cutting-edge engineering processes. The company has a long-standing reputation for producing high-quality chopper blades that are reliable, durable, and efficient. With a strong focus on research and development, the company constantly strives to enhance the performance and longevity of their products, while also keeping an eye on cost-effectiveness.

The recent price reduction for chopper blades is a result of the company's commitment to providing the best value to their customers. By optimizing their production processes and supply chain management, the company has been able to lower the manufacturing costs without compromising on the quality of the product. This cost-saving measure is a testament to the company's dedication to ensuring that their customers receive top-notch products at competitive prices.

The chopper blades are used by a wide range of customers, including helicopter manufacturers, aviation companies, and military organizations. The price reduction is expected to benefit not only the existing customers of the company, but also attract new customers who are looking for high-quality chopper blades at a more affordable price. The company's extensive experience and expertise in the aviation industry make them a trusted supplier of chopper blades to a global customer base.

In addition to the price reduction for chopper blades, the company is also known for providing exceptional customer support and after-sales service. They offer technical assistance, maintenance, and repair services for their products, ensuring that their customers can rely on the optimal performance of the chopper blades throughout their lifecycle. This commitment to customer satisfaction has earned the company a loyal and satisfied customer base, further solidifying their position as a leader in the aviation industry.

The company's chopper blades are designed and manufactured to meet the stringent quality and safety standards of the aviation industry. They undergo rigorous testing and inspection processes to ensure that they perform flawlessly in demanding operational conditions. With a focus on continuous improvement and innovation, the company is constantly exploring new technologies and materials to further enhance the performance and efficiency of their chopper blades.

The price reduction for chopper blades comes at a time when the aviation industry is facing various challenges, including volatile fuel prices and changing market dynamics. By offering competitive pricing for their products, the company aims to support their customers in navigating these challenges and achieving operational excellence. The company's extensive expertise in the aviation industry positions them as a valuable partner for their customers, who rely on the quality and reliability of their chopper blades for their critical operations.

In conclusion, the recent price reduction for chopper blades by the company is a demonstration of their unwavering commitment to delivering exceptional value to their customers. With a focus on cost efficiency and quality, the company continues to set new benchmarks in the aviation industry, providing high-performance chopper blades at competitive prices. This move is expected to benefit a wide range of customers and further strengthen the company's position as a trusted supplier of chopper blades in the global market.

Company News & Blog

High-quality Circular Cutting and Slotting Blades for Wood and Steel Cutting

When it comes to the production of carton cutting circular knives, Shanghai Zhengli Blade Manufacture Co., Ltd. is a company that is leading the way with quality and precision. The company manufactures high-quality circular cutting knives, long-form knives, arc knives, tooth shape knives, elongated cutting tools, trapezoidal points knives, wave shape knives, jagged blades, disc cutting knives, bending machine molds, machine tool accessories, cutting machine blades, and other products. Their blades are known for their super hard quality and durability, making them ideal for use in a wide range of industries.One of the most popular products from Shanghai Zhengli is the circular cutting knife, which is utilized in a variety of applications, including carton cutting. The company’s circular knives are designed to cut through a range of materials, including paper, cardboard, and plastics. The knives are available in various diameters and thicknesses, making them suitable for use in different types of cutting machines.Another popular product from Shanghai Zhengli is the slotting carton scimitar blade. The scimitar blade is designed to create precise cuts in corrugated cardboard boxes, allowing for easy folding and assembly. The blade is made from high-quality steel and is designed to withstand the rigors of high-volume production environments. The scimitar blade is available in different sizes and thicknesses, making it suitable for use in various types of corrugated box cutting machines.Shanghai Zhengli also manufactures steel cutting machine for circular blade Fujian cutter. This machine is used to cut steel plates and other materials with precision and accuracy. The circular blade is designed to make clean, burr-free cuts, ensuring that the finished product is of the highest quality. The Fujian cutter is highly versatile and can be used in a range of applications, including metal fabrication, automotive manufacturing, and construction.The company’s elongated cutting tools are also popular with customers. These tools are used to create intricate shapes and designs in a wide range of materials, including metal, plastic, and wood. The elongated cutting tools are available in a range of sizes and shapes, making them suitable for use in different types of cutting machines.Overall, Shanghai Zhengli Blade Manufacture Co., Ltd. is a company that is dedicated to providing high-quality cutting tools that meet the needs of their customers. Their products are designed to be durable, precise, and efficient, helping to increase productivity and reduce downtime. If you are looking for high-quality carton cutting circular knives or other cutting tools, Shanghai Zhengli is the ideal choice. So, if you want to improve your production efficiency and quality in carton cutting, consider investing in the products from Shanghai Zhengli Blade Manufacture Co., Ltd. today!

How to Cut Holes in Cement Backer Board with a Jigsaw: A Homeowner's Guide to Cutting Hardie Backer Board. Blade Options for Cutting Cement Backer Board.

for Effective Backer Board Installation. When it comes to installing tile or other types of flooring in your home, proper preparation is essential for a successful outcome. One of the most important steps is installing the right backer board. Hardie board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. However, cutting Hardie backer board can be a challenge without the right tools and techniques. In this post, we will discuss how to cut holes in cement backer board with a jigsaw and the importance of choosing the right Hardie plank cutting blade.Cutting Holes in Cement Backer Board with a JigsawMany DIY enthusiasts and professional contractors alike prefer using a jigsaw for cutting holes in cement backer board. With its fine-toothed blade, a jigsaw can make precise cuts quickly and easily. To get started, you will need the following tools:- A jigsaw with a fine-toothed blade - A straight edge - Safety glasses - Dust mask - Gloves Here are the steps to follow:1. Place the cement backer board on a work surface, such as a sawhorse or workbench.2. Use a straight edge to mark the shape of the hole you want to cut 3. Put on your safety glasses, dust mask, and gloves 4. Insert the jigsaw blade into the hole you have drilled in the cement backer board 5. Turn on the jigsaw and follow the outline you have marked on the backer board 6. Apply firm and steady pressure as you cut through the cement backer board Choosing the Right Hardie Plank Cutting BladeTo achieve a clean cut on your cement backer board, you must use the right type of blade. A Hardie plank cutting blade is specially designed to cut through fiber cement products like Hardie board. Here are some factors to consider when choosing the right blade:- Tooth configuration: The blade should have a double-row configuration with extra-sharp teeth to prevent chipping and splintering - Diameter: The diameter of the blade must be suitable for the type of tool you are using - Material: Choose a blade made of high-quality carbide-tipped material, which is durable and long-lasting In summary, Hardie backer board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. Cutting holes in cement backer board with a jigsaw is a great option for those who prefer a fine-toothed blade. To achieve a clean cut, it is essential to choose the right Hardie plank cutting blade. With these tips in mind, you can install your Hardie backer board with ease and confidence.

Affordable and Efficient Paint Scraper Blades for Your DIY Project

Title: Affordable Paint Scraper Blades: A Game-Changer for DIY EnthusiastsIntroduction:Painting projects around the house can be exciting and rewarding, but sometimes the tedious task of scraping off old, peeling paint can dampen the enthusiasm. However, thanks to Cheap Paint Scraper Blades, homeowners and DIY enthusiasts can now tackle their painting projects with ease and confidence. With their innovative and high-quality products, Cheap Paint Scraper Blades is revolutionizing the paint removal industry, providing affordable solutions for all.Background:Cheap Paint Scraper Blades is a pioneering company that specializes in developing and manufacturing cost-effective paint scraper blades. With a dedicated team of professionals, the company aims to simplify and enhance the paint removal process for homeowners, painters, and decorators worldwide. Offering a wide range of affordable options, Cheap Paint Scraper Blades makes it easier and more accessible for everyone to achieve professional-level results.Innovative Design:Unlike traditional paint scraper blades, Cheap Paint Scraper Blades have been meticulously engineered to provide exceptional performance. These blades feature a razor-sharp edge made from high-quality materials, ensuring maximum durability and longevity. The carefully crafted design allows for effortless paint removal, making the task significantly less time-consuming and physically demanding.Affordability:One of the standout features of Cheap Paint Scraper Blades is their affordability without compromising quality. Recognizing the budget constraints of many homeowners and DIY enthusiasts, the company strives to offer cost-effective solutions. By eliminating the need for expensive equipment or replacement blades, Cheap Paint Scraper Blades saves users both time and money. This affordability factor makes these blades an ideal choice for both occasional hobbyists and professional painters.Versatility:Cheap Paint Scraper Blades prides itself on providing versatility in its range of products. The company offers a variety of blade lengths and designs, catering to different paint removal needs. Their product catalog includes single-edge and double-edge blades, which can be easily attached to compatible handles or scrapers. This versatility ensures that customers can find the perfect match for their specific paint scraping requirements, regardless of the project size or complexity.User-Friendly Experience:Paint scraping can be a monotonous and labor-intensive task, but Cheap Paint Scraper Blades is dedicated to improving the overall user experience. The blades are ergonomically designed with a comfortable grip, reducing strain and fatigue during prolonged use. Additionally, their sharp edges ensure efficient paint removal without causing damage to underlying surfaces. With Cheap Paint Scraper Blades, anyone, regardless of their skill level, can achieve professional results while enjoying a hassle-free experience.Environmental Commitment:Cheap Paint Scraper Blades is committed to the environment and advocates for sustainable practices. The company manufactures their products using eco-friendly materials and adopts responsible production methods, minimizing their carbon footprint. Furthermore, their durable blades promote a "buy once, use for a long time" philosophy, reducing unnecessary waste generated from frequently replaced blades.Conclusion:Thanks to Cheap Paint Scraper Blades, the arduous task of removing paint has become easier, more affordable, and environmentally friendly. With their commitment to innovation, affordability, versatility, and user-friendliness, Cheap Paint Scraper Blades provides homeowners and DIY enthusiasts with a reliable tool they can depend on. By simplifying the paint removal process, this company empowers individuals to achieve professional-quality results while transforming their living spaces into works of art.

Reversible Screwdriver Blade for Maximum Durability - Phillips #2 + Slotted 6.0mm

for Precision Work, Wiha Phillips #2 Screwdriver Blade, Drive-Loc Handles, Collet Lock Handles, and Made in Germany.When it comes to working on delicate or intricate projects, having the right tools can make all the difference. That's why it's important to invest in high-quality blades like the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade.This blade is designed for use with both Drive-Loc and Collet Lock handles, giving you versatility in your toolkit. The blades are made from premium tool steel that has been through hardened and finished for maximum durability. This means you can rely on them to hold up to heavy use without losing their sharpness.One of the standout features of this blade is its double-ended design. With both a Phillips #2 screwdriver blade and a slotted 6.0mm (15/64") blade, you can easily switch between tasks without switching tools. This saves you time and effort, making it an ideal choice for professionals and DIY enthusiasts alike.As with all Wiha products, this blade is made in Germany to the highest standards of quality. You can trust that it will last you for years to come and give you excellent performance every time you use it.Whether you're working on precision electronics, appliances, or other household items, the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade is a must-have in your toolkit. Its high-quality slotted blades make it perfect for precision work, and its compatibility with Drive-Loc and Collet Lock handles make it a versatile choice for any project.Investing in the best tools means investing in top-quality blades like the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade. Add it to your toolkit today and experience the difference a high-quality blade can make.

Browse High-Quality Planer Blades and Accessories for Your Woodworking Needs

article about the importance of using high-quality planer blades for woodworking projects.As a woodworking professional, you understand the importance of using high-quality tools and equipment to achieve accurate and precise results. That's why investing in the right planer blades is essential to achieving superior quality output in every project.Planer blades are among the most critical tools in your arsenal for handling woodworking projects. These tools are responsible for shaping and leveling wood surfaces, which is why you need to choose the best planer blades for your applications.Here, we'll take a closer look at the importance of using high-quality planer blades in woodworking and how they can improve your output.PrecisionOne of the main advantages of using high-quality planer blades is precision. Good quality blades are precise and can achieve smoother, more even finishes. This precision can be essential when dealing with delicate or intricate wood pieces that require the utmost care.Reversible and Spiral BladesPROTRADE offers a range of planer blades for every woodworking need, including spiral and reversible blades. Reversible blades are versatile and can be flipped over for a fresh cutting edge, extending the life of the blade. They're also easy to replace, making them an excellent choice for woodworking professionals.Spiral blades, on the other hand, provide a superior cut surface quality, which is essential for high-end woodworking projects that require fine detail. Spiral blades offer great cutting performance and last longer than standard straight knives.DurabilityHigh-quality planer blades are made from high-quality materials, making them more durable than inferior blades. Durable blades are particularly advantageous in commercial woodworking shops where blades are used frequently and need to be replaced regularly.Using high-quality blades can also help prevent the need for frequent sharpening and blade replacements. This can be especially important for larger or more complex woodworking projects where efficient work and longer-lasting blades are crucial.Material CompatibilityDifferent materials and applications can require specific types of planer blades, which is another reason why it's essential to choose high-quality blades. Depending on the material you are workworking with, the blade's angle, length, and design will have an effect on the final output of your project.For instance, solid wood requires different blade designs compared to plywood or MDF. For harder or denser materials where more power is required, a blade with a steeper cutting angle may be required, while woods with a patterned grain may need blades with a shallower angle.In ConclusionIn summary, using high-quality planer blades can significantly enhance the quality of every woodworking project you undertake. Investing in the right blades, from high-quality brands like Festool and Virutex (remove brand name), is essential to achieving precise, even finishes and extending the life of your equipment.Whether you're a seasoned professional or just starting, using high-quality planer blades from PROTRADE can make a significant difference in the quality of your work. So why not upgrade your equipment today and see the difference for yourself?

Discover the Latest Insights on Tobacco Filter Rods Slitter Knives

Tobacco Filter Rods Slitter Knives: Revolutionizing Efficiency in Tobacco ProductionTobacco production has always been an industry that demands precision and efficiency. With the increasing demand for cigarettes across the globe, manufacturers constantly search for innovative solutions to improve their production processes. Recently, a pioneering company has launched a groundbreaking tool that is set to revolutionize the tobacco industry – the Tobacco Filter Rods Slitter Knives.Introducing a Perfect Harmony of Quality and EfficiencyThe Tobacco Filter Rods Slitter Knives, developed by a leading manufacturer in the field, are designed to offer a perfect harmony of quality and efficiency in the tobacco production process. With their state-of-the-art technology and meticulous craftsmanship, these knives are poised to transform the way filter rods are slit, resulting in significant improvements in production speed and accuracy.The company behind this groundbreaking invention has been a trailblazer in the tobacco machinery industry for over two decades. They have consistently delivered cutting-edge solutions that have helped tobacco companies streamline their production processes and enhance their product quality. Their deep understanding of the tobacco industry's requirements has enabled them to create tools that not only meet industry standards but also exceed expectations.Enhancing Efficiency and PrecisionThe Tobacco Filter Rods Slitter Knives are specifically designed to enhance the efficiency and precision of the tobacco production process. These knives are crafted with the highest quality materials, ensuring durability and longevity, even under demanding operating conditions. The company utilizes advanced manufacturing techniques and stringent quality control measures to guarantee exceptional performance.One of the key features of these knives is their ability to achieve precise slitting of filter rods. The intricate design and sharpness of the blades enable manufacturers to achieve consistent and accurate cuts, ensuring that each filter rod meets the desired specifications. This feature not only reduces waste in the production line but also ensures that the final product is of the highest quality.Furthermore, the Tobacco Filter Rods Slitter Knives are designed for easy installation and maintenance. The company provides comprehensive user manuals and technical support to assist customers in incorporating these knives seamlessly into their production systems. This user-friendly approach ensures that tobacco manufacturers can swiftly integrate this innovative tool into their existing processes, without causing disruptions or delays.Advancing the Tobacco IndustryThe introduction of the Tobacco Filter Rods Slitter Knives marks a significant milestone in the tobacco industry. This groundbreaking tool is set to revolutionize the way filter rods are slit, ultimately improving productivity, reducing waste, and enhancing the overall efficiency of tobacco production. By embracing this cutting-edge technology, manufacturers can stay ahead of the competition and meet the ever-growing demands of the tobacco market.With its commitment to innovation and continuous improvement, the company behind the Tobacco Filter Rods Slitter Knives ensures that its customers benefit from the latest advancements in the industry. They continue to invest in research and development, striving to create new solutions that address the evolving needs and challenges of tobacco manufacturers worldwide.ConclusionThe Tobacco Filter Rods Slitter Knives represent a game-changer for the tobacco industry, promising to streamline production processes and elevate product quality to new heights. As this revolutionary tool makes its mark in the market, tobacco manufacturers can look forward to improved efficiency, increased profitability, and enhanced customer satisfaction. With its combination of precision, durability, and ease of use, these knives undoubtedly have the potential to reshape the future of the tobacco production industry.

Top tips for choosing the best cigarette filter rods

Cut filter rods are an essential component of cigarettes, responsible for providing filtration and improving the smoking experience for consumers. These filter rods are produced by a renowned company, which has made a name for itself in the tobacco industry by consistently delivering high-quality products to its customers.The process of manufacturing cut filter rods involves the use of state-of-the-art technology and the expertise of skilled professionals. The company behind these filter rods prides itself on its commitment to quality, ensuring that each product meets the highest standards of excellence. This dedication to quality has earned the company a strong reputation in the industry and has helped solidify its position as a trusted provider of filter rods for leading tobacco brands.In addition to focusing on quality, the company places a strong emphasis on innovation. It continuously invests in research and development to explore new and improved ways of producing filter rods that meet the evolving needs and preferences of consumers. By staying at the forefront of technological advancements and industry trends, the company has been able to maintain its leadership position in the market and provide its customers with cutting-edge solutions.Furthermore, the company is committed to sustainability and environmentally responsible practices. It incorporates eco-friendly processes and materials into its production methods, ensuring that its operations have minimal impact on the environment. This commitment to sustainability aligns with the company's values and reflects its dedication to being a responsible corporate citizen.In recent industry news, the company has announced the launch of a new line of cut filter rods that are designed to offer enhanced filtration and smoking satisfaction. This innovative product line showcases the company's ongoing commitment to meeting the evolving needs of its customers and staying ahead of market demands. By introducing these advanced filter rods, the company aims to further solidify its position as a leading provider of high-quality tobacco products.The new line of cut filter rods features a combination of advanced filtration technology and premium materials, resulting in a product that delivers a smoother and more enjoyable smoking experience. These filter rods are meticulously designed to effectively remove harmful substances and impurities from the smoke, while maintaining the desired taste and aroma of the tobacco. This combination of functionality and sensory appeal sets the new filter rods apart and positions them as a standout offering in the market.In addition to their superior performance, the new filter rods also reflect the company's commitment to sustainability. They are manufactured using eco-friendly processes and materials, underscoring the company's dedication to reducing its environmental footprint. This sustainable approach aligns with the growing consumer demand for products that are both high-quality and environmentally responsible.The launch of the new line of cut filter rods represents a significant milestone for the company, demonstrating its ongoing dedication to innovation and excellence. By introducing these advanced products, the company is not only meeting the needs of its customers but also setting new industry standards for quality and sustainability. As the market for tobacco products continues to evolve, the company remains at the forefront, delivering products that exceed expectations and set the bar for excellence.With a strong focus on quality, innovation, and sustainability, the company continues to be a leading provider of cut filter rods for the tobacco industry. Its unwavering commitment to excellence and customer satisfaction has earned it a reputation as a trusted and reliable partner for leading tobacco brands. As the company moves forward, it will undoubtedly continue to shape the industry with its advanced products and dedication to meeting the needs of consumers.

Revolutionary Carbide Disposable Insert: Discover the Latest Advancements in Cutting Technology

Carbide Disposables – Revolutionizing the Industrial Manufacturing ProcessIn the industrial manufacturing process, the production of high-quality precision components requires the use of cutting-edge technology and the right tools. One critical component in this respect is Carbide Disposables, which have revolutionized the way manufacturers approach their manufacturing processes. Carbide Disposables are a type of cutting tool that is made with carbide, a type of material that is known for its durability and wear resistance.Carbide Disposables are used in various industrial applications, including woodworking, metalworking, and automotive manufacturing. They have become increasingly popular among manufacturers due to their superior cutting performance and extended durability. When compared to traditional steel or high-speed steel cutting tools, Carbide Disposables have a longer lifespan and can cut through materials with a higher degree of precision.As a market leader in the production of Carbide Disposables, our company has a proven track record in manufacturing the highest-quality cutting tools for industrial applications. Our company has been producing cutting tools since the early 1970s and has remained at the forefront of technological advancements in the industry. Our Carbide Disposables product line is a result of years of dedicated research and development, and our cutting-edge manufacturing process ensures that our tools are of the highest quality.Our Carbide Disposables are designed for a range of industrial applications and are available in various shapes and sizes. Our products are designed to meet the needs of customers across different industries, and we offer customized solutions to ensure that our customers get the best tools to fit their specific requirements. Our Carbide Disposables are made using the latest sintering and centerless grinding technologies, which means that they are precision-engineered and have incredibly consistent cutting performance.One of the biggest benefits of using Carbide Disposables is that they require less maintenance when compared to other cutting tools. This is because carbide is incredibly durable and wear-resistant, which means that our Carbide Disposables last longer than conventional cutting tools. This translates into a significant cost-saving for our customers as they do not have to replace cutting tools as frequently.Our Carbide Disposables are not just durable and long-lasting, they also offer superior cutting performance. This is because carbide is a harder material than steel, which means that it can cut through tougher materials with greater ease. Additionally, our Carbide Disposables are made with a precision-ground edge, which ensures that they cut through materials with a higher degree of accuracy. This translates into less waste material and increased efficiency in the manufacturing process.In conclusion, Carbide Disposables have revolutionized the industrial manufacturing process by offering superior cutting performance, enhanced durability, and reduced maintenance requirements. Our company's Carbide Disposables product line is a market leader in the industry, and we pride ourselves in offering customized solutions that meet the needs of our customers. Our Carbide Disposables are a testament to our company's commitment to excellence in manufacturing, and we will continue to develop new and innovative products to meet the evolving needs of the industrial manufacturing sector.

Largest Stock in USA for Diverse Slitter Blades

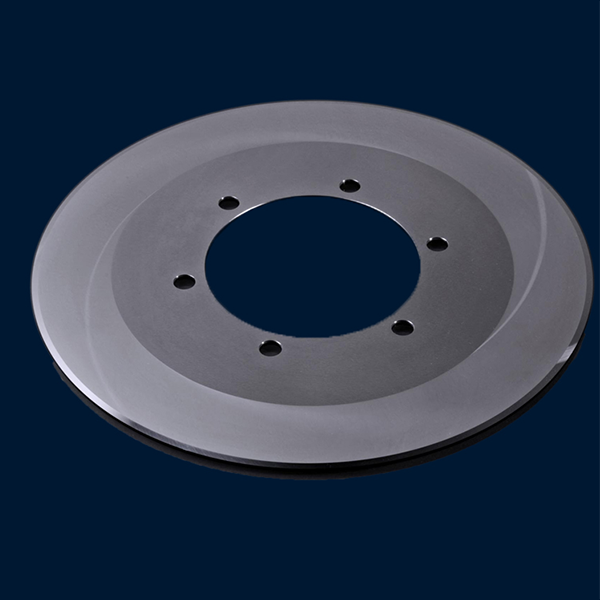

Blades for Converting and Slitting IndustryIn the converting and slitting industry, slitter blades, also known as slitter knives, play a critical role in the cutting and converting of various materials such as paper, film, foil, and other flexible substrates. The precision and quality of slitter blades directly impact the productivity, efficiency, and profitability of the converting processes.If you are looking for top-quality slitter blades for your business, you need to consider several factors such as the blade material, edge geometry, coating, and thickness. With the right combination of these factors, you can ensure optimal performance and longevity of your slitter blades.Top Slitter Knife Blades for Converting and Slitting IndustryOne of the leading providers of slitter blades in the USA is American Cutting Edge. They offer a comprehensive range of slitter blades for various converting and slitting applications. Let's discuss some of the top slitter knife blades that you can find at American Cutting Edge.1. Injector Blades: Injector blades are specially designed for perforating materials such as paper, tissue, and plastic film. These blades have a sharp point that penetrates the material without tearing or distorting it. American Cutting Edge offers a wide range of injector blades with different point styles and thicknesses to suit your specific requirements.2. 3-Hole Slitters: 3-hole slitters are used for cutting a wide range of materials such as paper, film, foil, and non-wovens. These blades feature three holes that allow for a better grip and alignment, resulting in precise and accurate cuts. American Cutting Edge offers 43mm 3-hole slitters with various edge configurations and coatings to improve the blade's wear resistance and durability.3. Slotted Blades: Slotted blades are used for cutting thicker materials such as cardboard and corrugated boxes. These blades have a slot in the center that allows for the removal of waste material. American Cutting Edge offers slotted blades with different slot widths, depths, and angles to achieve the desired cut quality.4. Razor Blades: Razor blades are ultra-thin and sharp blades that are used for cutting sensitive materials such as medical tapes and foils. These blades have a unique edge geometry that ensures clean and smooth cuts without damaging the material. American Cutting Edge offers a range of razor blades with different edge geometries, materials, and coatings to suit your cutting needs.ConclusionIn summary, slitter blades are essential components in the converting and slitting industry. With the right combination of blade material, edge geometry, coating, and thickness, you can achieve optimal performance and longevity of your blades. American Cutting Edge is a leading provider of top-quality slitter knife blades in the USA. Whether you need injector blades, 3-hole slitters, slotted blades, or razor blades, American Cutting Edge has got you covered. Contact them today to learn more about their slitter blades and how they can help improve your converting processes.

Newly Released Corrugated Paper Blades: A Breakthrough Technology for Enhanced Cutting Efficiency

Title: Innovation Driven Efficiency: Introducing Corrugated Paper Blades by [Company]Introduction:[Company], a leading player in the manufacturing industry, has unveiled a breakthrough product: Corrugated Paper Blades. With a proven commitment to innovation and a strong focus on customer satisfaction, [Company] has once again set an exemplary standard in the market. This news piece will delve into the features, benefits, and potential impacts of Corrugated Paper Blades by [Company].I. Overview of Corrugated Paper Blades:Corrugated Paper Blades are a pioneering solution developed by [Company] to enhance the efficiency and precision in cutting corrugated paper, one of the most commonly used materials in the packaging industry. These blades are specifically designed to meet the demanding requirements of corrugated paper production lines, offering improved durability, longevity, and cutting accuracy. With their enhanced design, Corrugated Paper Blades aim to revolutionize the manufacturing landscape for various industries reliant on corrugated packaging.II. Features and Benefits of Corrugated Paper Blades:a. Enhanced Durability: The Corrugated Paper Blades by [Company] are manufactured using cutting-edge materials and state-of-the-art technology, ensuring increased durability and prolonged lifespan. This feature helps reduce downtime due to blade replacements, optimizing operational efficiency and cost-effectiveness for businesses.b. Precise Cutting: The design of Corrugated Paper Blades incorporates advanced cutting edge geometries and sharpening techniques, resulting in unparalleled precision during the cutting process. This not only enhances the overall quality of the finished products but also minimizes production waste, leading to improved profitability for manufacturers.c. Customizability: Recognizing the diverse needs of its customers, [Company] offers Corrugated Paper Blades in various sizes and configurations. This flexibility allows businesses to find the perfect fit for their specific corrugated paper cutting requirements, further optimizing their operations.d. Eco-Friendly Solution: In line with [Company]'s commitment to sustainability, Corrugated Paper Blades are manufactured using eco-friendly materials and production processes. This eco-conscious approach ensures that end-users can reduce their carbon footprint while benefiting from the product's exceptional performance.III. Impact on Industries:The introduction of Corrugated Paper Blades by [Company] is expected to have a significant positive impact on various industries, particularly those heavily reliant on corrugated packaging. Some of the key effects include:a. Improved Productivity: By providing accurate and efficient cutting, Corrugated Paper Blades will streamline production processes, which in turn will boost overall productivity. Manufacturers will witness a reduction in material wastage, downtime, and rework, leading to higher output and profitability.b. Enhanced Quality Control: With precision cutting capabilities, Corrugated Paper Blades will contribute to the consistent production of high-quality corrugated paper products. This will strengthen the brand reputation of businesses and improve customer satisfaction.c. Cost Optimization: Corrugated Paper Blades' enhanced durability and longer lifespan contribute to reduced maintenance costs and fewer blade replacements. Consequently, businesses can allocate their resources more effectively and invest in other growth opportunities.d. Sustainability: The adoption of Corrugated Paper Blades aligns with the growing global trend of sustainability in manufacturing. By using eco-friendly materials and production processes, businesses can improve their environmental credentials and cater to increasingly conscious consumer demands.Conclusion:[Company]'s innovative Corrugated Paper Blades demonstrate their commitment to driving efficiency and customer satisfaction. With enhanced durability, cutting precision, and eco-friendly features, these blades offer numerous benefits to manufacturers relying on corrugated packaging. By embracing this cutting-edge solution, businesses can optimize their operations, enhance productivity, deliver high-quality products, and contribute to a sustainable future.