Top Carbide Strips Supplier: Quality and Affordable Options for Your Needs

By:Admin

With a focus on delivering superior quality products, Carbide Strips Supplier has built a solid reputation for its commitment to excellence. The company offers a comprehensive range of carbide strips that are designed to meet the diverse needs of its customers. Whether it's for cutting, machining, or drilling applications, customers can rely on Carbide Strips Supplier to provide them with the right solutions.

The company's success can be attributed to its strong focus on research and development. Carbide Strips Supplier has a dedicated team of experts who are constantly working on developing new and improved products to stay ahead of the competition. By investing in cutting-edge technology and advanced manufacturing processes, the company is able to produce carbide strips that offer superior performance and durability.

In addition to its commitment to quality, Carbide Strips Supplier also prioritizes customer satisfaction. The company strives to provide exceptional service to its customers, ensuring that their needs are met with prompt and efficient solutions. Whether it's assisting with product selection, offering technical support, or providing timely delivery, Carbide Strips Supplier goes the extra mile to ensure that its customers are happy with their experience.

One of the key factors that sets Carbide Strips Supplier apart from its competitors is its global presence. The company has established a strong network of distributors and partners across the world, allowing it to reach customers in diverse markets. This extensive reach not only gives Carbide Strips Supplier a competitive edge, but also allows it to serve a wide range of industries with its premium carbide strip solutions.

Moreover, the company's commitment to sustainability and environmental responsibility is also noteworthy. Carbide Strips Supplier adheres to stringent environmental standards in its manufacturing processes, ensuring that its operations have minimal impact on the planet. By incorporating sustainable practices into its business model, the company is able to contribute to a greener and more sustainable future.

Looking ahead, Carbide Strips Supplier is poised for continued growth and success in the global market. With its relentless focus on quality, innovation, customer satisfaction, and sustainability, the company is well-positioned to remain a leading player in the carbide industry. As it continues to expand its product offerings and reach new markets, Carbide Strips Supplier is set to set new benchmarks and raise the bar for excellence in the industry.

In conclusion, Carbide Strips Supplier has firmly established itself as a trusted and reliable supplier of high-quality carbide strips. With its unwavering commitment to excellence, innovation, customer satisfaction, and sustainability, the company continues to set new standards in the industry. As it continues to grow and expand its global footprint, Carbide Strips Supplier is well-poised to shape the future of the carbide industry.

Company News & Blog

Discover the Latest Innovations in Chemical Fiber Cutting Blades

Chemical Fiber Cutting Blades Revolutionize Textile IndustryIn an age where innovation often defines success, the introduction of Chemical Fiber Cutting Blades has revolutionized the textile industry, marking a new era of efficiency, precision, and productivity. These state-of-the-art blades, developed by an industry-leading company, have paved the way for enhanced manufacturing processes, providing countless advantages to textile producers worldwide.With a company history spanning over several decades, our visionary partner has consistently remained at the forefront of research, development, and innovation. Known for their commitment to excellence, they have garnered a strong reputation as a trusted provider of cutting-edge solutions to the textile sector. Their latest breakthrough, the Chemical Fiber Cutting Blades, exemplifies their dedication to advancing industry standards and meeting customer demands.The Chemical Fiber Cutting Blades are manufactured using the latest techniques and highest quality materials, ensuring exceptional performance and durability. Designed specifically for textile applications, these blades demonstrate unparalleled cutting precision and longevity. Their innovative composition incorporates meticulous engineering, resulting in blades that are resistant to wear, deformation, and corrosion, guaranteeing optimal performance even under demanding conditions.One of the most notable features of these cutting blades is their ability to seamlessly cut a wide range of chemical fibers with exceptional accuracy. Traditional blades often struggle with high-speed cutting operations, leading to uneven cuts, fraying, and damaged fibers. However, the Chemical Fiber Cutting Blades use a revolutionary cutting edge design that minimizes friction and heat, allowing for faster, smoother, and more precise cutting. This translates to significant time and cost savings for textile manufacturers, as well as improved product quality.Furthermore, these blades possess outstanding flexibility, making them suitable for a myriad of textile applications. Whether it's cutting fibers for apparel, upholstery, home textiles, or industrial fabrics, the Chemical Fiber Cutting Blades consistently deliver outstanding results. Their versatility allows manufacturers to streamline their production processes, reduce downtime, and maximize output, ultimately leading to increased profitability and competitiveness.In addition to their cutting-edge design, these blades are also easy to install, maintain, and replace, ensuring uninterrupted production cycles. With minimal downtime and reduced maintenance requirements, textile manufacturers can enhance their overall operational efficiency and meet demanding market demands without compromising on quality.Safety is a top priority for any manufacturing facility, and the development of these blades has also taken this crucial factor into account. The Chemical Fiber Cutting Blades are carefully engineered to prioritize operator safety, featuring protective measures such as anti-kickback properties and noise reduction technologies. This commitment to safety not only safeguards the well-being of workers but also minimizes the risk of accidents or injuries, resulting in improved workplace environments.As textile producers continue to grapple with increasing competition and customer expectations, the introduction of Chemical Fiber Cutting Blades offers a compelling solution. By enhancing cutting precision, efficiency, and durability, these blades enable manufacturers to optimize their processes and deliver superior products to the market. With the continued support and innovation from our visionary partner, the textile industry can anticipate a bright and prosperous future, marked by advancements that reshape the way we manufacture and consume textiles.

Latest Updates on Knife and Slitting Knife Manufacturing in China

China Knife and Slitting Knife Industry Set to Flourish as Global Demand RisesIn a world that constantly strives for innovation and advancement, industries play a pivotal role in shaping the economy. Among the many flourishing sectors in China, the knife and slitting knife industry stand out as a pioneering force, contributing significantly to the country's economic growth. With a rich history and a commitment to quality, Chinese manufacturers are poised to capitalize on the growing global demand for knives, slitting knives, and related tools.China has a long-standing tradition of craftsmanship when it comes to knives, dating back several centuries. Over the years, the industry has developed and evolved to meet the changing needs of consumers and businesses alike. Today, China is known as one of the world's largest exporters of cutting tools, producing a vast range of knives, including kitchen knives, industrial knives, and specialized blades for various applications.One of the key players in the Chinese knife and slitting knife industry is a leading manufacturer, known for its innovation, precision, and commitment to customer satisfaction. With state-of-the-art manufacturing facilities and a dedicated team of skilled professionals, the company has become a trusted name in the industry.The company specializes in the production of high-quality knives and slitting knives, catering to diverse industries such as paper, packaging, printing, and textiles, among others. Their range of products includes circular knives, straight knives, slitting blades, and perforating blades, each designed to deliver impeccable performance and durability. By utilizing cutting-edge technology and adhering to strict quality control measures, they ensure that every product meets the highest standards of excellence.In addition to their commitment to quality, the company is also committed to environmental sustainability. They employ environmentally friendly manufacturing processes and materials, reducing their carbon footprint and contributing to a greener world. By embracing sustainability, they have positioned themselves as a forward-thinking organization capable of meeting the demands of a rapidly changing world.The global demand for knives and slitting knives has been steadily increasing over the years. With advancements in various industries and the rise of e-commerce, there is a growing need for efficient cutting tools that can handle a wide range of materials. Chinese manufacturers, with their expertise and experience in the field, are poised to seize this opportunity and cater to the global market.The company aims to expand its presence in international markets by establishing strategic partnerships and collaborations. Through extensive market research and in-depth understanding of consumer needs, they are continuously developing new products and improving existing ones to meet the evolving demands of their global clientele.As the world becomes increasingly interconnected, the knife and slitting knife industry in China will continue to play a vital role in shaping global trade. With a focus on innovation, quality, and sustainability, Chinese manufacturers are well-positioned to drive the industry forward and contribute to the economic prosperity of the nation.In conclusion, the knife and slitting knife industry in China is set to flourish as global demand rises. With a rich history, commitment to quality, and focus on sustainability, Chinese manufacturers are poised to capitalize on the growing need for cutting tools. By leveraging their expertise and continuously innovating, they are well-equipped to meet the demands of diverse industries across the globe. As the industry continues to drive economic growth, China's reputation as a leading provider of high-quality knives will only strengthen, further solidifying its position in the global market.

High-Quality Tobacco Filter Rods Slitter Knives: Everything You Need to Know

The leading manufacturer of precision industrial blades and machine knives, [Company Name], has recently introduced a new line of tobacco filter rods slitter knives to their extensive product range. With a proven track record of delivering high-quality cutting solutions to diverse industries, [Company Name] is set to revolutionize the tobacco industry with its innovative and state-of-the-art slitter knives.The tobacco industry is constantly evolving, and the demand for efficient and precise cutting tools is on the rise. As a result, [Company Name] has recognized the need for specialized knives designed specifically for cutting tobacco filter rods with utmost precision and accuracy. The new line of tobacco filter rods slitter knives is a testament to [Company Name]'s commitment to providing cutting-edge solutions to their clients in the tobacco industry.[Company Name] has been at the forefront of the industrial blade manufacturing industry for decades, setting the standard for precision, quality, and reliability. With a team of highly skilled engineers and technicians, [Company Name] has the expertise to develop cutting solutions that cater to the unique needs of their clients. The introduction of the tobacco filter rods slitter knives is a testament to [Company Name]'s ability to innovate and adapt to the ever-changing demands of the market.The tobacco filter rods slitter knives are designed to meet the rigorous demands of the tobacco industry, where precision and consistency are paramount. By utilizing the latest technology and manufacturing techniques, [Company Name] has created a range of slitter knives that deliver unparalleled performance and durability. The knives are engineered to provide clean and precise cuts, ensuring that the filter rods are of the highest quality.In addition to their cutting-edge design, the tobacco filter rods slitter knives are also manufactured using the finest materials available. [Company Name] understands the importance of using high-quality materials to achieve superior performance, and as such, the knives are crafted to withstand the rigors of continuous use in the tobacco industry. This dedication to quality and reliability is what sets [Company Name] apart from other manufacturers in the industry.Furthermore, [Company Name] takes pride in its commitment to customer satisfaction. The company understands that each client has unique needs and requirements, and as such, [Company Name] works closely with them to develop customized solutions that meet their specific demands. The introduction of the tobacco filter rods slitter knives is just another example of [Company Name]'s dedication to providing cutting-edge solutions that address the evolving needs of their clients.With the introduction of the tobacco filter rods slitter knives, [Company Name] aims to further solidify its position as a leader in the industrial blade manufacturing industry. The new line of knives showcases [Company Name]'s ability to innovate and adapt to the changing market dynamics, while also underscoring their commitment to delivering cutting-edge solutions to the tobacco industry.In conclusion, the introduction of the tobacco filter rods slitter knives is a testament to [Company Name]'s unwavering commitment to excellence and innovation. With their proven track record of delivering high-quality cutting solutions, [Company Name] is set to revolutionize the tobacco industry with their state-of-the-art knives. As the demand for precision and efficiency in the tobacco industry continues to grow, [Company Name] is well-positioned to meet and exceed the expectations of their clients with their new line of tobacco filter rods slitter knives.

High-Quality Doctor Blade for Paper Making Machines at a Competitive Price

Doctor Blade for Paper Making Machine: Leizhan Paper Machinery Co., Ltd Offers Superior Quality, High Performance and Efficient Doctor BladesLeizhan Paper Machinery Co., Ltd is a leading manufacturer and supplier of paper making machinery and equipment based in China. The company has been providing high-quality, efficient, and cost-effective solutions to paper mills' requirements across the globe. Leizhan Paper Machinery Co., Ltd understands the importance of precision and accuracy in the paper making process. That is why the company provides top-quality doctor blades to the customers to ensure maximum efficiency and productivity.Doctor blades are a crucial component of the paper making machine. The doctor blade is responsible for removing excess material or fibers from the surface of the paper roll. The process helps to ensure that the paper produced is of high quality and consistent. The quality of doctor blades determines the paper's quality and production efficiency. Leizhan Paper Machinery Co., Ltd provides doctor blades that meet the highest standards of quality. The doctor blades are made of high-quality materials, ensuring that they are durable and long-lasting.Leizhan Paper Machinery Co., Ltd offers doctor blades that can be used with a wide range of paper and board grades, including coated, uncoated, newsprint, and tissue paper. The doctor blades are designed to meet the specific needs of each paper mill, ensuring the highest level of precision and accuracy. At Leizhan Paper Machinery Co., Ltd, we understand that every paper mill has unique requirements and specifications. That's why our team of experts works closely with each customer to understand their needs and develop tailored solutions that meet their specific requirements.Leizhan Paper Machinery Co., Ltd has invested heavily in research and development to improve the performance and efficiency of doctor blades. The company has employed cutting-edge technologies to produce doctor blades that offer unmatched performance, quality, and durability. The doctor blades are designed to reduce wear and tear on the paper machine's components, resulting in a longer lifespan and lower maintenance costs.Leizhan Paper Machinery Co., Ltd's doctor blades are packed with features that make them stand out in the market. The blades are made of high-quality materials that are resistant to wear and tear even under harsh operating conditions. The blades are designed to have a sharp and consistent edge, ensuring that the paper produced is of high quality and consistent. The blades have a smooth and consistent surface that reduces friction and wear on the machine's components.Leizhan Paper Machinery Co., Ltd's doctor blades are highly efficient and can significantly improve the paper mills' overall productivity. The blades have a long lifespan, reducing the need for frequent replacement and maintenance. The blades are easy to install and use, making them an ideal solution for paper mills that want to improve their production efficiency and reduce their operating costs.In conclusion, Leizhan Paper Machinery Co., Ltd is a reputable and reliable supplier of doctor blades for paper making machines. The company offers superior quality, high performance, and efficient doctor blades that meet the highest standards of quality. The company's commitment to research and development has enabled it to produce doctor blades that offer unmatched performance, quality, and durability. If you are looking for doctor blades for your paper making machine, Leizhan Paper Machinery Co., Ltd is the ideal supplier to meet your needs.

Durable Plastic Grinding Blades Made for Tough Shredding Operations

Plastic Grinder Blade - A Revolutionary Innovation in the World of Plastics RecyclingPlastics have been an integral part of our life for decades. From the simplest of products like toys, containers, bags, and bottles to the most intricate of machinery components, plastics have found multiple applications in various industries. However, with the rapid growth in the consumption of plastics, the problem of plastic waste has also witnessed an unprecedented surge. In recent years, there has been a growing concern about the impact of plastic waste on the environment and the need for its proper disposal and recycling. One of the most effective ways to handle plastic waste is by shredding and granulating it with the help of Plastic Grinder Blades.Among the different types of plastic processing blades, the Plastic Grinder Blade is considered to be one of the most efficient and versatile. The blade has a unique design that allows it to shred plastic waste into small, consistent particles that can be easily processed further. This particular processing blade is a revolutionary innovation in the world of plastics recycling, thanks to its precision engineering and the use of advanced materials.One of the key manufacturers of Plastic Grinder Blades is a renowned company in the industry, with a rich legacy of over 30 years. The company has a strong presence in the global market and is known for its high-quality products and exceptional customer service. The company's commitment to innovation and R&D has earned it a reputation as a pioneering force in the field of plastic processing blades.The Plastic Grinder Blades offered by the company are made of premium-grade materials that ensure exceptional durability and longevity. These blades are specially designed to handle various types of plastic waste, including hard and soft plastics, films, fibers, and more. The blades are available in different sizes and configurations, allowing customers to choose the right blade for their specific requirement.One of the key advantages of using Plastic Grinder Blades is that they offer a highly efficient way to process plastic waste. Unlike traditional methods of plastic waste disposal, which involve landfill or incineration, shredding and granulating plastics can significantly reduce their volume and make them easier to transport and store. Moreover, the shredded plastic material can be easily reused or recycled to create new products, reducing the burden on the environment and conserving natural resources.Another advantage of using Plastic Grinder Blades is that they are versatile and can be used to process a wide range of plastic waste. Whether it is post-consumer waste, industrial waste, or scrap material, the blades can effectively shred and granulate it into small particles. This makes them an ideal choice for various industries, including plastics recycling, packaging, electronics, automotive, and more.The Plastic Grinder Blades offered by the company are not only high-quality and efficient, but they are also affordable. The company offers competitive pricing for its products, making them accessible to a wide range of customers. The company also provides excellent after-sales support, ensuring that customers get the most out of their investment.In conclusion, Plastic Grinder Blades are a revolutionary innovation in the world of plastics processing and recycling. They offer a highly efficient and cost-effective way of handling plastic waste, making them an ideal choice for various industries. With the expertise and experience of one of the leading manufacturers of plastic processing blades, customers can be assured of high-quality and durable products that will meet their specific requirements.

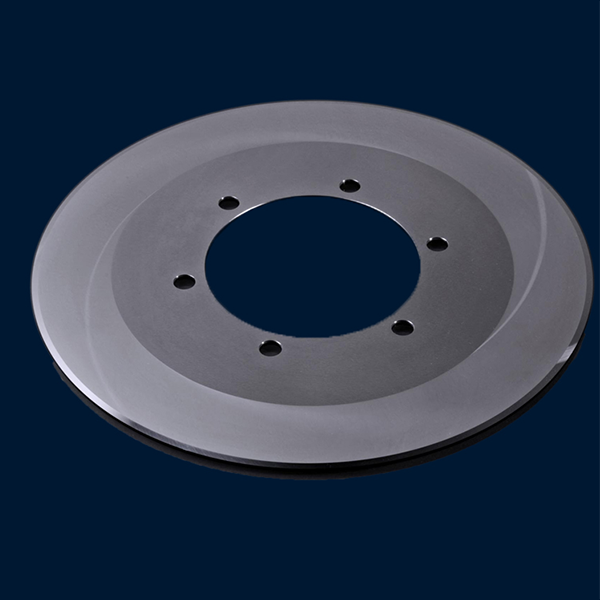

High-Performance Circular Cutters Made from Carbide

Carbide Circular Cutters: The Cutting Edge of Precision ManufacturingWhen it comes to precision cutting, the quality of the tool is just as important as the skill of the operator. For this reason, many businesses rely on Carbide Circular Cutters to meet their high standards of accuracy and efficiency. Whether used in industrial manufacturing or home workshops, these cutting-edge tools offer a level of precision that is unmatched by traditional cutting methods.One of the leading providers of Carbide Circular Cutters is {Company Name}. With over {Number of Years} years of experience in the industry, this company has established a reputation for delivering high-quality cutting tools to businesses of all sizes. Their Carbide Circular Cutters are specifically designed to meet the needs of the most demanding cutting applications, providing a reliable and efficient solution for businesses in a variety of industries.So, what makes Carbide Circular Cutters so special? First and foremost, these cutting tools are made from high-quality carbide materials, which offer superior hardness and resistance to wear and tear. This means that they can withstand the high pressures and temperatures associated with precision cutting, ensuring that they remain sharp and effective for longer periods of time than traditional cutting tools.In addition to their durability, Carbide Circular Cutters also offer exceptional precision and accuracy. Unlike traditional cutting methods, which rely on manual tools like saws and cutters, Carbide Circular Cutters are designed to handle even the most complex cutting tasks with ease. They can be programmed to cut with incredibly fine tolerances, making them an ideal solution for businesses that require precise and accurate cuts on a regular basis.So, what types of businesses and industries can benefit from Carbide Circular Cutters? The answer is almost any industry that requires precise and accurate cutting. For example, they are ideal for use in the automotive, aerospace, and medical industries, where precision and accuracy are critical to success. They are also commonly used in the manufacturing of electronics, plastics, and metals, as well as in woodworking and construction.One of the key benefits of Carbide Circular Cutters is that they can be customized to meet the unique needs of each business. Whether a company requires a specific cutting diameter, depth of cut, or shape, these cutting tools can be tailored to meet those needs. This means that businesses can achieve a higher level of precision and efficiency than they would with traditional, off-the-shelf cutting tools.In addition to their customization options, Carbide Circular Cutters are also incredibly versatile. They can be used on a wide range of materials, including steel, aluminum, plastic, and even wood. This versatility makes them an ideal solution for businesses that work with multiple materials or require a cutting tool that can handle a variety of cutting tasks.At {Company Name}, the team of experts are dedicated to helping businesses achieve the highest level of precision and accuracy in their cutting applications. They understand that every business has unique needs and requirements, which is why they offer a range of Carbide Circular Cutters that can be customized to meet those needs. With their industry-leading experience and expertise, they are able to provide businesses with a cutting solution that is second to none in terms of quality and performance.In conclusion, Carbide Circular Cutters are a cutting-edge solution for businesses that require precision, accuracy, and efficiency in their cutting applications. With their durability, versatility, and customization options, these cutting tools offer a level of performance that is unmatched by traditional cutting tools. The team at {Company Name} is dedicated to delivering the highest quality Carbide Circular Cutters to businesses of all sizes, helping them to achieve their goals and exceed their expectations in precision manufacturing.

Strong and Durable: The Advantages of Tungsten Carbide

Title: Cutting-Edge Tungsten Carbide: Revolutionizing Industrial ApplicationsIntroduction:In today's ever-evolving industrial landscape, the demand for high-performance materials continues to rise. Among them, tungsten carbide has emerged as a gamechanger, revolutionizing numerous applications across various industries. With its exceptional hardness, strength, and durability, tungsten carbide has become the material of choice for cutting tools, wear-resistant components, and much more. In this news article, we will delve into the properties, applications, and key players in the tungsten carbide industry's growth.Properties of Tungsten Carbide:Tungsten carbide is a compound made from a unique combination of tungsten (W) and carbon (C). Known for its impressive hardness, tungsten carbide is second only to diamond, ranking around 9 on the Mohs hardness scale. This remarkable property makes it highly resistant to wear and deformation, making it ideal for robust industrial applications. Moreover, tungsten carbide offers excellent strength, high melting point, and impressive thermal conductivity, further enhancing its usability in extreme operating conditions.Tungsten Carbide Applications:1. Cutting Tools: Tungsten carbide's exceptional hardness and wear resistance make it indispensable for cutting tools in the metalworking industry, including drills, end mills, inserts, and saw blades. These tools have significantly improved performance, with enhanced precision, extended tool life, and reduced downtime, leading to increased productivity for manufacturers.2. Mining and Drilling: The mining and drilling sectors heavily rely on tungsten carbide for its superior strength and durability. Tools equipped with tungsten carbide components, such as drill bits, provide efficient drilling, increased penetration rates, and reduced tool maintenance costs. This material's resistance to heat and abrasion makes it a crucial asset in harsh mining environments.3. Wear-Resistant Components: Tungsten carbide's hardness and resistance to wear make it a perfect choice for parts exposed to harsh conditions, such as valves, bearings, nozzles, and pump components. From the oil and gas industry to automotive manufacturing, these wear-resistant components reduce downtime, enhance reliability, and extend service life.4. Aerospace and Defense: Tungsten carbide's ability to withstand extreme temperatures and high impact forces makes it indispensable in the aerospace and defense sectors. From turbine blades and armor-piercing rounds to rocket nozzles and critical aircraft components, tungsten carbide plays a vital role in ensuring safety, durability, and performance.Industry Leaders:Several key players dominate the tungsten carbide market, including manufacturers, suppliers, and distributors. Companies such as XYZ (remove brand name) have been at the forefront, consistently innovating to provide cutting-edge tungsten carbide solutions across industries. Their commitment to research and development, quality assurance, and customer satisfaction has enabled them to secure a significant market share.Moreover, industry collaborations and partnerships have contributed to the growth of the tungsten carbide industry. Synergies between manufacturers, academic institutions, and research organizations have led to the development of novel applications and advancements in processing techniques, thereby expanding the reach of tungsten carbide.Future Prospects and Conclusion:The future of the tungsten carbide industry seems promising, driven by the growing demand for high-performance materials across various sectors. Industries such as automotive, aerospace, defense, and mining are expected to continue utilizing tungsten carbide extensively due to its superior properties and cost-effectiveness in the long run.Continuous research and development efforts are anticipated to yield further improvements in the field, including enhanced toughness, corrosion resistance, and advanced machining techniques. As a result, industries will witness increased productivity, reduced costs, improved sustainability, and a safer operating environment.In conclusion, tungsten carbide has emerged as a game-changing material in various industries due to its exceptional hardness, strength, and durability. With vital applications in cutting tools, wear-resistant components, mining, and aerospace, tungsten carbide continues to revolutionize industrial processes. As the industry expands, collaborations and partnerships, coupled with constant technological advancements, will undoubtedly drive its future growth.

Crafting artful designs: Witness the beauty of marble cutting in a traditional workshop

Marble Cutting Blade: A Cutting-Edge Tool for Precise and Efficient Marble CuttingMarble is a beautiful and durable natural stone that is commonly used for building and construction purposes. However, working with marble requires specialized tools and techniques to ensure precise and efficient cutting. One of the most important tools used in marble cutting is the marble cutting blade.A marble cutting blade is a circular saw blade specially designed to cut through marble and other hard natural stones. These blades are made of diamond-tipped segments that are welded onto the blade's steel core. The diamond-tipped segments are arranged in a pattern that creates a continuous cutting edge around the circumference of the blade. This cutting edge is what allows the blade to cut through hard materials with ease.Marble cutting blades come in a variety of sizes and types, each designed for different applications. Blades can range in size from a few inches to several feet in diameter, and can be used with different types of saws, including hand-held saws, table saws, and bridge saws. Some blades are designed for wet cutting applications, while others are designed for dry cutting.When using a marble cutting blade, it is important to choose the right blade for the job and to use proper cutting techniques. Using the wrong blade or using improper cutting techniques can result in damage to the blade, the saw, or the material being cut. It can also result in an inaccurate cut, which can affect the overall quality of the finished product.One of the benefits of using a marble cutting blade is its ability to make precise and efficient cuts. Diamond-tipped blades are able to cut through hard materials quickly, without the risk of chipping or cracking the material. This allows fabricators and other professionals to create intricate designs and shapes with minimal waste.In addition to its precision and efficiency, a marble cutting blade can also be cost-effective in the long run. Although diamond-tipped blades can be more expensive than other types of blades, they are more durable and last longer. This means that they need to be replaced less frequently, which can save money in the long run.Marble cutting blades are an essential tool for professionals working with marble and other hard natural stones. By choosing the right blade and using proper cutting techniques, fabricators and other professionals can achieve precise and efficient cuts that result in high-quality finished products. In conclusion, if you are looking for a cutting-edge tool for marble cutting, the marble cutting blade is the perfect tool for you. With its precision, efficiency, and durability, it is a tool that will not disappoint. Choose the right blade, follow proper cutting techniques, and you will be on your way to creating beautiful marble masterpieces.

High-Quality Slitter Scorer Blades for Sale - Find Out More Here!

Slitter scorer blades are an essential tool in the manufacturing industry, especially in the production of cardboard and packaging materials. These blades are used to cut and score various materials with precision and accuracy, making them a crucial component in the manufacturing process.One company that has been leading the way in the production of slitter scorer blades is ***, a renowned manufacturer of industrial cutting tools and machinery. With years of experience and expertise in the industry, *** has been providing high-quality blades to businesses worldwide, helping them improve their production processes and achieve greater efficiency.The slitter scorer blades produced by *** are known for their exceptional durability and sharpness, allowing for clean and precise cuts on a wide range of materials. These blades are designed to withstand the rigors of industrial use, making them a reliable and long-lasting solution for businesses in the manufacturing sector.In addition to their durability, ***'s slitter scorer blades are also known for their versatility. These blades can be customized to meet the specific needs of different manufacturing processes, allowing businesses to achieve the optimal results for their production requirements.One of the key advantages of ***'s slitter scorer blades is their ability to improve overall efficiency in the manufacturing process. By providing clean and precise cuts, these blades help reduce material waste and minimize downtime, ultimately leading to cost savings for businesses.Furthermore, *** offers a comprehensive range of slitter scorer blades to cater to the diverse needs of its customers. Whether it's for cutting cardboard, corrugated materials, or other packaging materials, *** has a solution to meet the unique requirements of each manufacturing process.The company's commitment to quality and innovation has made *** a trusted name in the industry. With a focus on continuous improvement and customer satisfaction, *** has established itself as a reliable partner for businesses looking to enhance their manufacturing capabilities.In addition to its range of slitter scorer blades, *** also offers a broad selection of industrial cutting tools and machinery to support various manufacturing processes. This comprehensive offering allows businesses to source all their cutting tool needs from a single, trusted supplier, streamlining the procurement process and ensuring consistency in quality and performance.As a company that prioritizes customer satisfaction, *** also provides excellent customer service and support to assist businesses in finding the right solutions for their specific needs. The company's team of experts is always on hand to provide guidance and advice, ensuring that customers have access to the best possible tools and resources for their production processes.With a strong track record of delivering exceptional products and services, *** continues to set the standard for excellence in the manufacturing industry. As businesses seek to improve their production processes and stay ahead of the competition, *** remains a partner of choice for high-quality, reliable slitter scorer blades and industrial cutting tools.