High-Quality Circular Cutting Knives for Precision Cuts

By:Admin

Circular cutting knives are essential tools in many industries, providing precision cutting and durability for a wide range of applications. These knives are commonly used in manufacturing, recycling, and packaging industries, where accuracy and efficiency are crucial for the production process. One company at the forefront of circular cutting knife production is __ (remove brand name), a leading manufacturer of industrial cutting tools.

Established in 1985, __ (remove brand name) has been committed to providing high-quality cutting solutions for industrial applications. With a strong focus on research and development, the company has continued to innovate and improve its products to meet the evolving needs of its customers. __ (remove brand name) has built a strong reputation for its superior quality circular cutting knives, backed by state-of-the-art manufacturing processes and a team of experienced engineers and technicians.

One of the key factors that set __ (remove brand name) apart from its competitors is its dedication to precision engineering. The company utilizes advanced technologies and materials to ensure that its circular cutting knives meet the highest standards for accuracy and performance. Whether it is for cutting paper, plastics, textiles, or metal, __ (remove brand name)’s knives are designed to deliver clean and precise cuts, minimizing material waste and maximizing productivity.

In addition to precision, durability is another hallmark of __ (remove brand name)’s circular cutting knives. The company understands the demanding nature of industrial environments, where cutting tools are subjected to heavy usage and challenging materials. As a result, __ (remove brand name) has developed a range of high-strength, wear-resistant knives that can withstand the rigors of continuous operation. This durability not only extends the lifespan of the knives but also reduces maintenance costs for its customers.

__ (remove brand name)’s commitment to quality extends beyond its products to its customer service and support. The company works closely with its clients to understand their specific cutting needs and offers customized solutions to meet those requirements. Whether it is modifying blade geometries, coatings, or materials, __ (remove brand name) is dedicated to providing its customers with the best cutting tools for their applications.

Furthermore, __ (remove brand name) places a strong emphasis on sustainability and environmental responsibility in its manufacturing processes. The company is dedicated to reducing waste and energy consumption, as well as minimizing its carbon footprint. By investing in green technologies and processes, __ (remove brand name) aims to contribute to a more sustainable future for the industry and the planet.

As part of its ongoing commitment to excellence, __ (remove brand name) continues to invest in research and development to further enhance its circular cutting knives. The company recognizes the importance of staying ahead of industry trends and is constantly exploring new materials, coatings, and manufacturing techniques to improve the performance and lifespan of its products.

In conclusion, circular cutting knives are indispensable tools in various industrial applications, and __ (remove brand name) has established itself as a leading manufacturer in this field. With its focus on precision, durability, and customer satisfaction, the company has earned a strong reputation for delivering high-quality cutting solutions. As the industry continues to evolve, __ (remove brand name) remains committed to innovation, sustainability, and providing the best possible cutting tools for its customers.

Company News & Blog

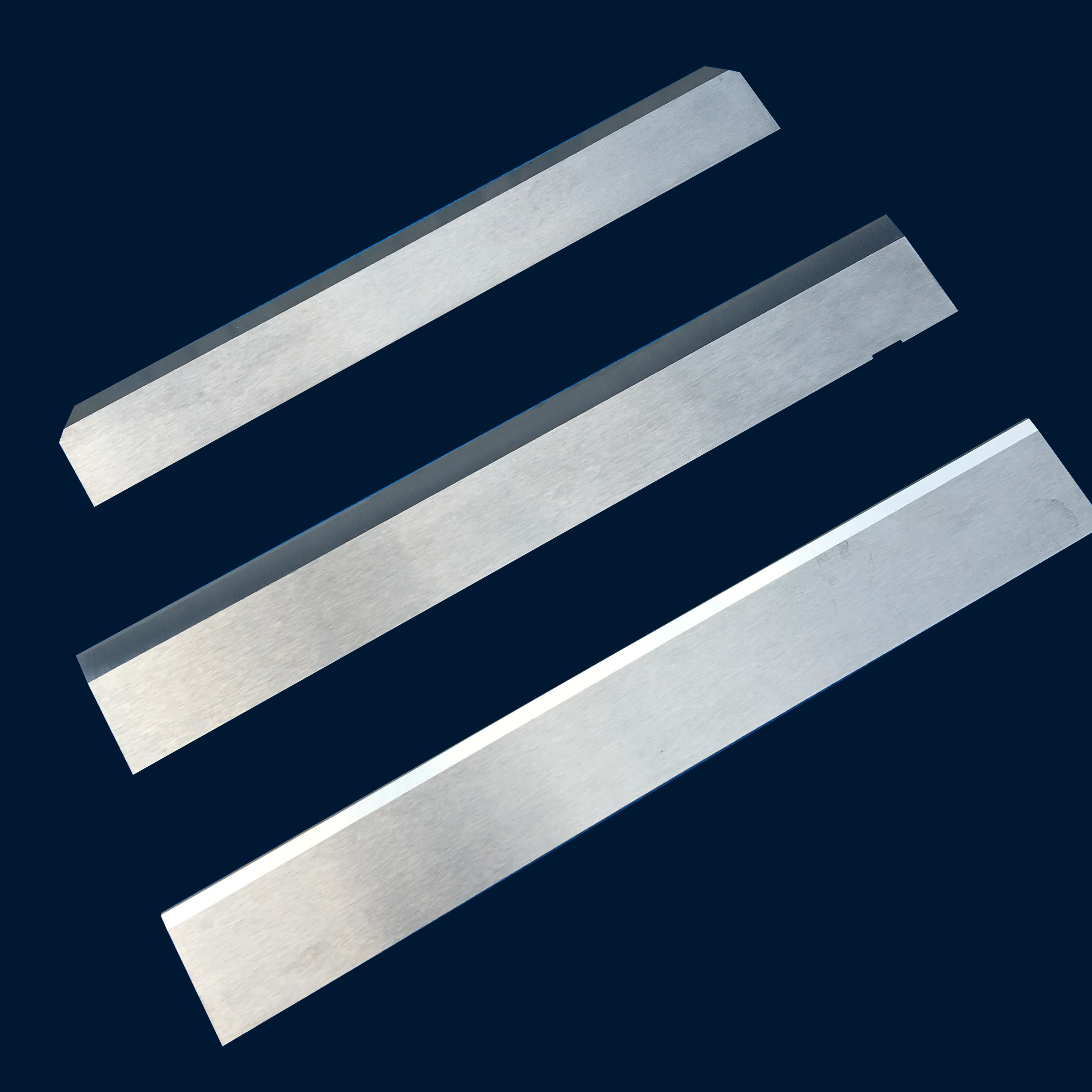

Ultimate Guide to Choosing the Perfect Planer Knife for Woodworking Projects

Planer Knife Sets New Standard for Precision and DurabilityTool manufacturing has always been a competitive industry, with companies continuously striving to develop innovative products that are efficient, reliable, and durable. One such company has recently set a new benchmark in the field with its latest revolutionary invention – the Planer Knife.Incorporating cutting-edge technology and years of expertise, this pioneering company, which prefers to remain anonymous for the purpose of this article, has successfully designed a planer knife that surpasses all existing industry standards. Through a meticulous process of research, testing, and experimentation, they have introduced a product that is set to transform the woodworking industry.With the rise in demand for high-quality woodwork, the need for precision tools has become increasingly vital. Traditional planer knives often fail to deliver consistent and accurate results, resulting in wasted time, effort, and resources. Recognizing this gap in the market, the anonymous company identified the importance of developing a planer knife that could meet the unique needs of contemporary craftsmen.The newly released Planer Knife has been engineered to perfection, offering exceptional precision and durability. The company has employed state-of-the-art technology to craft a blade that is not only razor-sharp but also highly resistant to wear and tear. This ensures that woodworkers can achieve the smoothest finishes with minimal effort, saving significant amounts of time and money.One of the standout features of this advanced planer knife is its unique composition. The blade is constructed using a proprietary blend of high-grade materials that have been specifically chosen for their exceptional hardness and longevity. This design allows the knife to retain its sharpness even after prolonged use, guaranteeing consistent and unparalleled performance throughout its lifespan.Additionally, the Planer Knife boasts an innovative design that enhances its versatility. The company's team of experienced engineers have carefully crafted the blade to be compatible with a wide range of planers, catering to the diverse requirements of woodworkers across the industry. This adaptability ensures that craftsmen can seamlessly integrate the Planer Knife into their existing tools, avoiding the need for costly upgrades.Furthermore, the anonymous company has prioritized the safety and ease of use of the Planer Knife. The blade is equipped with a series of intuitive features, including ergonomic handles and a secure locking mechanism, ensuring that woodworkers can operate the knife confidently and effectively. This focus on user-friendly design allows even amateur craftsmen to achieve professional-level results, democratizing the woodworking industry.The introduction of the Planer Knife has already generated considerable excitement within the woodworking community. Woodworkers have praised the knife for its unparalleled sharpness, precision, and longevity, noting that it outperforms all other planer knives currently available in the market. Many professionals have expressed their appreciation for the anonymous company's commitment to revolutionizing the industry, and eagerly anticipate future innovations from their workshop.In conclusion, the anonymous company behind the Planer Knife has showcased their dedication to excellence with the development of this groundbreaking tool. Through cutting-edge technology, meticulous craftsmanship, and a commitment to customer satisfaction, they have succeeded in creating a planer knife that exceeds all expectations. Woodworkers around the world can now benefit from this exceptional tool that sets a new standard for precision and durability, allowing them to achieve unparalleled results in their woodworking endeavors.

Boost Your Cutting Precision with High-Quality Plotter Blades

[Introduction]In the ever-evolving world of industrial cutting tools, Plotter Blades (brand name omitted) have emerged as a prominent player, offering high-quality and efficient solutions for various applications. With a commitment to innovation, durability, and precision, Plotter Blades has become a go-to choice for professionals seeking excellence in their cutting tasks. With a comprehensive range of products, this company has garnered a solid reputation in the market, delivering exceptional performance and reliability to customers worldwide.[Company Overview]Plotter Blades, founded by a team of industry experts, has swiftly established itself as a leading manufacturer of cutting-edge blades, designed to meet the diverse needs of its customers. The company's primary focus lies in producing blades that are both durable and precise, ensuring smooth and accurate cutting performance across a wide range of materials. With an unwavering commitment to quality, Plotter Blades continues to push the boundaries of blade technology, constantly striving to exceed customer expectations.[Product Range]The product portfolio of Plotter Blades encompasses an extensive range of blades, catering to various industries such as automotive, packaging, textile, signage, and advertising. Each blade is meticulously designed and crafted to fulfill specific cutting requirements, ensuring optimal results for professionals in their respective fields.The company offers blades suitable for different cutting machines, including vinyl cutters, digital plotters, CNC routers, and oscillating knife cutters. These blades are available in a variety of materials such as tungsten carbide, high-speed steel, and ceramic, allowing customers to choose the most appropriate option for their specific applications.[Innovation and Technology]Plotter Blades prides itself on its continuous efforts to develop and incorporate cutting-edge technology into its products. By staying at the forefront of technological advancements, the company ensures its customers benefit from the latest innovations in the industry.Utilizing advanced manufacturing techniques, Plotter Blades ensures consistent quality and superior performance in every blade. The company's research and development team constantly works to refine blade designs, resulting in improved cutting efficiency and extended blade life. This commitment to innovation has positioned Plotter Blades as a trusted brand among professionals seeking the best possible cutting solutions.[Quality Control]Maintaining stringent quality control measures is a top priority for Plotter Blades. From selecting high-grade raw materials to rigorous testing at every stage of production, the company leaves no stone unturned in ensuring its blades meet the highest standards. Stringent quality control protocols are in place, including comprehensive inspection and analysis, to guarantee that each blade leaving the factory is flawless in terms of durability, sharpness, and accuracy.[Catering to Customer Needs]Plotter Blades understands that the success of its customers relies on their ability to deliver superior results. As a result, the company places great emphasis on understanding the specific needs of its customers and tailoring its products accordingly. With a team of technical experts, Plotter Blades offers personalized guidance and support to help customers select the most suitable blades for their applications, ensuring they achieve optimal cutting performance.[Market Presence]With a strong presence in both domestic and international markets, Plotter Blades is dedicated to providing its exceptional products and services to customers around the globe. The company's commitment to customer satisfaction and its ability to consistently deliver high-quality blades have earned it a loyal customer base and established its reputation as a reliable market player.[Conclusion]Plotter Blades stands as a beacon of innovation and excellence in the field of industrial cutting tools. Its unwavering commitment to quality, cutting-edge technology, and customer satisfaction places it at the forefront of the industry. As Plotter Blades continues to expand its product range and reach new heights of success, professionals can rely on its blades to meet their cutting needs with precision and efficiency.

Top Recommendations for High-Quality Razor Blades

Croma Razor Blades: Revolutionizing the Shaving ExperienceShaving has been one of the most essential personal care activities for men across the globe. However, it is not uncommon to hear men complaining about the discomfort and irritation caused by blades while shaving. To address this issue, Croma – a leading blade manufacturer – has come up with a revolutionary product that offers a smooth and comfortable shaving experience – Croma Razor Blades.Croma Razor Blades are designed to deliver a perfect shave with minimal irritation and discomfort. They are made of premium quality materials and have an advanced coating that helps reduce friction and prevent skin irritation. The blades are precision-engineered to cut through even the toughest of hair with ease, providing a clean and smooth finish.The brand has successfully managed to capture a significant market share with its innovative product which has been widely accepted by consumers worldwide. Croma Razor Blades has become a household name when it comes to shaving essentials.Croma Razor Blades – Built to deliver a Superior Shaving ExperienceCroma Razor Blades boast an impressive design which provides a superior shaving experience like never before. These blades are designed to provide optimal comfort, improved glide and lasting sharpness. The blades are made of high quality, corrosion-resistant materials that help maintain their sharpness even after multiple shaves.The razor blades are coated with a special non-stick substance that ensures minimal resistance during the shave, resulting in smoother and comfortable results. The customized coating also resists the buildup of hair and skin debris, thereby ensuring that the blades remain clean throughout the shave.The blades are designed to offer uniform pressure and contact on every stroke, thereby reducing irritation and bumps. The blades are also engineered to offer a perfect balance between rigidity and flexibility, which ensures a close and precise shave without causing discomfort.Safety is a top priority for the company. Croma Razor Blades feature a unique safety guard that helps prevent nicks, cuts, and irritation during the shave. The safety guard also helps to pull the skin taut, providing a smooth surface for the blades to glide through.Innovative Design: What Makes Croma Razor Blades Stand OutCroma Razor Blades are also popular because of their innovative product design that ensures superior shaving performance. The blades come in various designs ranging from the traditional razor to the modern cartridge. The traditional razor design features a single blade that offers precision shaving, while the cartridge features multiple blades, which offer a close and comfortable shave.The company also offers the Croma Pro-Glide Technology that ensures a smooth and effortless shave. This added advantage is suitable for those with sensitive skin who are prone to razor burn or irritation.The Croma Razor Blades also boast a sturdy and ergonomically designed handle that provides a firm grip and enables more precise control over the shave. The handle features finger notches that provide added grip and reduce slippage during the shave.Croma Razor Blades – An Environmentally Conscious BrandCroma is also an environmentally conscious brand that recognizes the importance of sustainable production. The company uses eco-friendly processes and materials, which helps reduce the impact of manufacturing on the environment.ConclusionIn conclusion, Croma Razor Blades are a game-changer that has revolutionized the shaving experience. The blades deliver unmatched quality, comfort, and safety, thanks to their superior design, sharpness, and specialized coatings. The brand's commitment to environmentally friendly practices only adds to their appeal. Croma Razor Blades are a must-have item for those who demand the ultimate shaving experience. Try them today, and you'll be amazed at the difference they make.

High-quality Custom Carbide Knives for Precision Cutting

Custom Made Carbide Knives{Company name} is proud to announce the launch of a new line of custom-made carbide knives for industrial and manufacturing applications. This new product line is designed to provide maximum efficiency and durability for cutting and slicing tasks in a wide range of industries.Carbide is a material known for its durability and hardness, making it an excellent choice for knife blades that need to maintain their cutting edge for extended periods of time. {Company name} has leveraged its expertise in manufacturing and engineering to create custom carbide knives that meet the specific needs of its clients.The company's custom-made carbide knives are available in a variety of shapes, sizes, and configurations to suit different cutting applications. Whether it's cutting through tough materials such as plastic, rubber, or metal, {Company name}'s carbide knives are designed to deliver exceptional performance and longevity.One of the key advantages of carbide knives is their ability to maintain a sharp cutting edge for longer periods compared to traditional steel blades. This is particularly beneficial for industries that require precision cutting and high production volumes. The use of carbide knives can result in improved efficiency and reduced downtime for blade changes, leading to cost savings and increased productivity.Furthermore, {Company name} offers custom grinding and honing services to ensure that its carbide knives meet the exact specifications of its clients. This customization capability allows the company to work closely with customers to design and produce knives that are tailored to their specific cutting needs.In addition to its custom-made carbide knives, {Company name} also provides comprehensive technical support and consultation to help customers select the right knives for their applications. The company's team of experts can assist with blade selection, material recommendations, and performance optimization to ensure that customers achieve the best results with their carbide knives.{Company name} takes pride in its commitment to quality and customer satisfaction. All of its carbide knives are manufactured to the highest standards using advanced CNC machining and precision grinding techniques. The company's state-of-the-art manufacturing facilities enable it to produce custom knives with tight tolerances and exceptional consistency."We are thrilled to introduce our custom-made carbide knives to the market," said {Spokesperson's name}, {position} at {Company name}. "With our extensive experience in precision engineering and manufacturing, we are confident that our carbide knives will deliver superior performance and reliability for a wide range of cutting applications."The launch of {Company name}'s custom-made carbide knives represents a significant milestone for the company as it continues to expand its product offerings and serve the evolving needs of its customers. By leveraging its expertise in material science and engineering, the company is well-positioned to deliver innovative cutting solutions that meet the demands of modern manufacturing and industrial processes.For businesses looking to improve their cutting operations, {Company name}'s custom-made carbide knives offer a compelling solution. With their exceptional durability, sharpness, and customized design options, these knives are set to make a significant impact in various industries.To learn more about {Company name}'s custom-made carbide knives and other cutting solutions, please visit {company website} or contact the company directly to discuss specific requirements and applications.

Discover the Best Paint Scraper Blades for Effective Surface Removal

Title: Paint Scraper Blades: High-Quality Tools for Efficient Surface PreparationIntroduction:In the realm of surface preparation, Paint Scraper Blades have continually proven their efficacy in achieving smooth and polished finishes. Known for their exceptional quality and durability, these versatile tools are widely used by professionals and DIY enthusiasts alike. Manufactured with precision and engineered to handle various materials, Paint Scraper Blades ensure a seamless and hassle-free paint removal process, making them an indispensable tool in any toolkit.[Company Name], a renowned manufacturer of high-quality paint scraper blades, has witnessed tremendous success in the industry due to their commitment to excellence and customer satisfaction. With a diverse range of innovative products, the company has positioned itself as a market leader, catering to the needs of professionals in the painting and decorating industry.Body:1. Introduction to Paint Scraper Blades: - Paint scraper blades are essential tools for any surface preparation job, aiding in the efficient removal of paint, varnish, and other coatings. - Traditionally made from high-grade steel, these blades are engineered to resist wear and tear, ensuring a long lifespan and optimal performance.2. [Company Name]: Revolutionizing Surface Preparation: - [Company Name] is a leading manufacturer of paint scraper blades, trusted by professionals worldwide for their exceptional quality and craftsmanship. - The company's commitment to innovation, coupled with extensive research and development, has allowed them to create cutting-edge scraper blade designs. - [Company Name]'s state-of-the-art manufacturing facilities adhere to strict quality control processes, guaranteeing consistent and reliable products.3. Specialized Blades for Different Surface Preparation Needs: - [Company Name] offers a comprehensive range of paint scraper blades tailored to meet specific surface preparation requirements. - The company's lineup includes multi-edge blades, carbide-tipped blades, and extended reach blades, ensuring versatility and efficiency in various projects. - Their carbide-tipped blades provide exceptional durability and are specially designed to handle tough surfaces such as concrete, brick, and metal.4. Professional-Grade Durability and Performance: - Paint Scraper Blades by [Company Name] are known for their exceptional durability, enabling professionals to undertake demanding tasks without frequent replacements. - The blades' precise cutting edge allows for effortless paint removal, reducing the need for excessive force and minimizing the risk of damage to the underlying surface. - Designed with ergonomics in mind, [Company Name]'s blades offer a comfortable grip, reducing hand fatigue during extended periods of use.5. Customer Satisfaction and Industry Recognition: - [Company Name] takes pride in its commitment to customer satisfaction and has built a strong reputation for providing top-notch products and services. - With a focus on continuous improvement, the company actively seeks customer feedback to enhance product performance and design. - Their dedication to quality has earned them accolades within the industry, with numerous professionals relying on their blades for superior surface preparation results.Conclusion:Paint Scraper Blades by [Company Name] have become synonymous with quality and efficiency in surface preparation. With their commitment to innovation and customer satisfaction, the company has solidified its position as a market leader in manufacturing top-grade scraper blades. Whether it is paint removal, varnish stripping, or general surface preparation, professionals and DIY enthusiasts can rely on [Company Name]'s versatile and durable products to achieve outstanding finishes.

High-Quality Cutting and Blade Manufacturing in China

China Cutting and Blade Industry Continues to Thrive in 2021China is known for its expertise in manufacturing and production, and the cutting and blade industry is no exception. With the continued growth of the global economy and the increasing demand for high-quality cutting and blade products, China has emerged as a leader in the industry. One company that has been at the forefront of this development is {}.{} is a leading manufacturer of cutting and blade products in China. With a history of over 20 years in the industry, the company has established itself as a trusted and reliable supplier of cutting and blade products for a wide range of applications. From industrial cutting tools to consumer-grade blades, {} provides high-quality products that meet the needs of its customers.The company's success can be attributed to its commitment to innovation and quality. {} has invested heavily in research and development, continuously exploring new materials and manufacturing techniques to improve the performance and durability of its products. This dedication to innovation has allowed the company to stay ahead of the competition and meet the evolving needs of the market.In addition to its focus on innovation, {} also places a strong emphasis on quality control. The company has implemented rigorous quality assurance processes throughout its manufacturing facilities to ensure that every product that leaves its factory meets the highest standards of quality and performance. As a result, {} has built a reputation for producing cutting and blade products that are reliable, durable, and cost-effective.Furthermore, {} is committed to sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing practices and uses recyclable materials whenever possible. By minimizing its environmental impact, {} is not only contributing to a greener planet but also meeting the growing demand for sustainable products in the market.In recent years, {} has experienced significant growth, driven by the increasing demand for cutting and blade products both domestically and internationally. The company's products are widely used in various industries, including manufacturing, construction, automotive, and agriculture. With a strong focus on product development and customer satisfaction, {} has successfully expanded its market reach and established a loyal customer base around the world.Looking ahead, {} is poised for even greater success in the cutting and blade industry. The company is committed to staying at the forefront of innovation, continuously improving its products to meet the evolving needs of the market. With a strong focus on quality, sustainability, and customer satisfaction, {} is well-positioned to continue its growth and maintain its position as a leader in the industry.As the global economy continues to recover from the impact of the COVID-19 pandemic, the demand for cutting and blade products is expected to further increase, presenting new opportunities for {} and other manufacturers in the industry. With its proven track record of excellence and commitment to innovation, {} is primed to capitalize on these opportunities and further solidify its position as a leader in the cutting and blade industry.

Top Circular Blade Options for Cutting Efficiency

Circular Blade, a leading manufacturer of industrial cutting tools and equipment, has announced the launch of its newest cutting-edge product. The company, known for its innovative and reliable products, has once again set the bar high with the introduction of the new Circular Blade.The Circular Blade is designed to meet the ever-evolving needs of the manufacturing and industrial sectors, offering precision and efficiency in cutting materials such as metal, wood, plastic, and more. With its advanced technology and high-performance features, the Circular Blade aims to streamline cutting processes and enhance overall productivity for businesses."We are thrilled to introduce our latest innovation, the Circular Blade, to the market," said the spokesperson for Circular Blade. "As a company committed to excellence, we continuously strive to develop cutting-edge solutions that meet the demands of our valued customers. The Circular Blade is a testament to our dedication to providing top-quality cutting tools that deliver exceptional performance and reliability."The Circular Blade is crafted with superior quality materials and undergoes rigorous testing to ensure durability and longevity. Its precision-engineered design allows for smooth and seamless cutting, reducing material waste and maximizing efficiency in various industrial applications. Whether used for straight cuts, bevel cuts, or other specific applications, the Circular Blade offers unmatched versatility and consistency.In addition to its impeccable performance, the Circular Blade is also designed with user-friendly features, making it easy to install and operate. Its ergonomic design and intuitive controls ensure convenience and safety for operators, further solidifying its position as a game-changer in the cutting tool industry.Furthermore, Circular Blade offers a range of customization options for the Circular Blade, allowing businesses to tailor the tool to their specific needs and requirements. From size variations to specific cutting capabilities, the company aims to provide tailored solutions that cater to the diverse needs of its clientele.Circular Blade has been a trusted name in the industry for over two decades, consistently delivering top-of-the-line products and unparalleled customer service. With a strong emphasis on research and development, the company continues to push the boundaries of innovation, setting new standards for cutting tools and equipment.The launch of the Circular Blade is a testament to Circular Blade's commitment to excellence and its relentless pursuit of technological advancement. By introducing a cutting-edge product that redefines precision and efficiency in cutting processes, the company reinforces its position as a leading force in the industry.As businesses across various sectors seek to optimize their operations and maximize productivity, the Circular Blade presents itself as a valuable asset, offering a competitive edge through its advanced cutting capabilities.With the introduction of the Circular Blade, Circular Blade is not only revolutionizing the cutting tool industry but also empowering businesses to achieve new heights of efficiency and performance. As businesses embrace this innovative solution, it is clear that Circular Blade continues to be at the forefront of driving progress and innovation in industrial cutting technology.

High-Quality Slitting Blades for Lithium Battery Chips: A Guide to Manufacturers and Suppliers

and Lithium Battery Chip Slitting Knife throughout the content.The demand for advanced lithium batteries is surging worldwide. Lithium-ion batteries, in particular, are popular among electronic device manufacturers due to their high efficiency, durability, and long shelf life. However, the lithium-ion battery production process is not without its challenges. One of the critical steps in the production process is chip slitting. Chip slitting involves cutting the anode and cathode material into thin strips to divide the electrodes. For this process, battery manufacturers require reliable and high-quality lithium battery chip slitting blades/knives.There are several manufacturers of lithium battery chip slitting blades/knives in China. These blades/knives are available in various sizes, shapes, and materials. The most commonly used materials for these blades/knives are tungsten carbide, ceramic, and diamond. Each material has its unique characteristics and benefits.Tungsten Carbide Blades/KnivesTungsten carbide blades/knives are the most widely used type of lithium battery chip slitting blades/knives. These blades/knives are made of tungsten carbide, a hard and durable material that can withstand high levels of wear and tear. Tungsten carbide blades/knives are ideal for cutting through thick and hard materials, making them ideal for lithium battery chip slitting.Ceramic Blades/KnivesCeramic blades/knives are also popular for lithium battery chip slitting. These blades/knives are made of zirconia or alumina, which are highly resistant to wear and corrosion. Ceramic blades/knives are lightweight, making them easy to handle, and they generate less heat during the cutting process. These characteristics make ceramic blades/knives ideal for high-precision cutting applications.Diamond Blades/KnivesDiamond blades/knives are the most expensive type of lithium battery chip slitting blades/knives, but they are also the most durable. These blades/knives are made of a diamond-coated carbide material, which can easily cut through hard and abrasive materials. Diamond blades/knives are ideal for cutting through materials like silicon anodes, which are challenging to cut with other types of blades/knives.ConclusionChoosing the right type of lithium battery chip slitting blades/knives is critical to the efficiency and production quality of a lithium-ion battery. Tungsten carbide, ceramic, and diamond blades/knives are the most popular materials used for this purpose. Each material has its advantages and disadvantages, so it is essential to choose the right blade/knife based on the specific needs of the manufacturer. Regardless of the type of blade/knife selected, it is essential to work with reliable and high-quality manufacturers who use advanced production techniques to ensure consistent and accurate cuts. Battery slitting blade and lithium battery chip slitting knife are essential tools in the production process of lithium-ion batteries, and choosing the right one can make the difference between a successful and failed project.

Newly Released Corrugated Paper Blades: A Breakthrough Technology for Enhanced Cutting Efficiency

Title: Innovation Driven Efficiency: Introducing Corrugated Paper Blades by [Company]Introduction:[Company], a leading player in the manufacturing industry, has unveiled a breakthrough product: Corrugated Paper Blades. With a proven commitment to innovation and a strong focus on customer satisfaction, [Company] has once again set an exemplary standard in the market. This news piece will delve into the features, benefits, and potential impacts of Corrugated Paper Blades by [Company].I. Overview of Corrugated Paper Blades:Corrugated Paper Blades are a pioneering solution developed by [Company] to enhance the efficiency and precision in cutting corrugated paper, one of the most commonly used materials in the packaging industry. These blades are specifically designed to meet the demanding requirements of corrugated paper production lines, offering improved durability, longevity, and cutting accuracy. With their enhanced design, Corrugated Paper Blades aim to revolutionize the manufacturing landscape for various industries reliant on corrugated packaging.II. Features and Benefits of Corrugated Paper Blades:a. Enhanced Durability: The Corrugated Paper Blades by [Company] are manufactured using cutting-edge materials and state-of-the-art technology, ensuring increased durability and prolonged lifespan. This feature helps reduce downtime due to blade replacements, optimizing operational efficiency and cost-effectiveness for businesses.b. Precise Cutting: The design of Corrugated Paper Blades incorporates advanced cutting edge geometries and sharpening techniques, resulting in unparalleled precision during the cutting process. This not only enhances the overall quality of the finished products but also minimizes production waste, leading to improved profitability for manufacturers.c. Customizability: Recognizing the diverse needs of its customers, [Company] offers Corrugated Paper Blades in various sizes and configurations. This flexibility allows businesses to find the perfect fit for their specific corrugated paper cutting requirements, further optimizing their operations.d. Eco-Friendly Solution: In line with [Company]'s commitment to sustainability, Corrugated Paper Blades are manufactured using eco-friendly materials and production processes. This eco-conscious approach ensures that end-users can reduce their carbon footprint while benefiting from the product's exceptional performance.III. Impact on Industries:The introduction of Corrugated Paper Blades by [Company] is expected to have a significant positive impact on various industries, particularly those heavily reliant on corrugated packaging. Some of the key effects include:a. Improved Productivity: By providing accurate and efficient cutting, Corrugated Paper Blades will streamline production processes, which in turn will boost overall productivity. Manufacturers will witness a reduction in material wastage, downtime, and rework, leading to higher output and profitability.b. Enhanced Quality Control: With precision cutting capabilities, Corrugated Paper Blades will contribute to the consistent production of high-quality corrugated paper products. This will strengthen the brand reputation of businesses and improve customer satisfaction.c. Cost Optimization: Corrugated Paper Blades' enhanced durability and longer lifespan contribute to reduced maintenance costs and fewer blade replacements. Consequently, businesses can allocate their resources more effectively and invest in other growth opportunities.d. Sustainability: The adoption of Corrugated Paper Blades aligns with the growing global trend of sustainability in manufacturing. By using eco-friendly materials and production processes, businesses can improve their environmental credentials and cater to increasingly conscious consumer demands.Conclusion:[Company]'s innovative Corrugated Paper Blades demonstrate their commitment to driving efficiency and customer satisfaction. With enhanced durability, cutting precision, and eco-friendly features, these blades offer numerous benefits to manufacturers relying on corrugated packaging. By embracing this cutting-edge solution, businesses can optimize their operations, enhance productivity, deliver high-quality products, and contribute to a sustainable future.

Ultimate Guide to Choosing Rotary Machine Knives: Industry Insights and Expert Advice

Title: Innovating Precision and Efficiency: Rotary Machine Knives Redefine Cutting TechnologyIntroduction:In the ever-evolving world of industrial machinery, one company stands out for its commitment to precision, efficiency, and cutting-edge technology. Rotary Machine Knives, a key player in the industry, has gained a global reputation for delivering high-quality products that streamline cutting processes across several sectors. With a comprehensive range of rotary machine knives and an unwavering dedication to innovation, the company continues to revolutionize cutting technology, making operations faster, smoother, and more cost-effective for countless businesses worldwide.1. Pioneering Cutting-Edge Technology:Rotary Machine Knives has a distinguished history of pioneering cutting-edge technology that raises the bar in the industry. With an unwavering focus on research and development, the company constantly pushes the boundaries of what is possible in cutting applications. By leveraging the latest advancements in materials, engineering, and automation, Rotary Machine Knives has managed to introduce several groundbreaking products to the market.One such product is their state-of-the-art [insert innovative product name]. This ground-breaking rotary knife combines [insert key features] to provide unprecedented precision and efficiency in cutting applications. Designed to meet the diverse needs of industries such as packaging, paper converting, textile, and more, this innovative tool enables businesses to optimize their processes, reduce waste, and enhance productivity significantly.2. Extensive Product Portfolio:Rotary Machine Knives boasts an extensive product portfolio that caters to a wide range of cutting requirements across various industries. From blade sharpeners to circular knives, slitters, perforators, and sheeters, the company offers comprehensive solutions that address the specific needs of their clients.Their high-quality rotary machine knives are manufactured using premium materials and employ cutting-edge engineering techniques. This ensures maximum lifespan, exceptional cutting performances, and minimal downtime. In addition, the company provides customizable solutions, allowing businesses to tailor their rotary machine knives to suit their unique applications and preferences.3. Industry-Specific Applications:Recognizing the diverse needs of different industries, Rotary Machine Knives has developed specialized solutions for specific applications. In the printing and packaging industry, their rotary machine knives deliver precise cutting of paper, labels, plastic films, and even complex patterns. The textile industry benefits from their seamless cutting of fabrics and other materials, ensuring efficient production processes.Moreover, Rotary Machine Knives caters to the demanding needs of the food processing industry, offering hygiene-approved blades that cut through meat, fruits, and vegetables with unparalleled precision and hygiene. These industry-specific solutions have positioned the company as a trusted partner across various sectors, where precision and quality are crucial for success.4. Commitment to Customer Satisfaction:Apart from their cutting-edge technology and comprehensive product range, Rotary Machine Knives prides itself on its dedication to customer satisfaction. The company values long-term relationships with its clients, emphasizing collaborative partnerships and efficient support.By providing expert guidance and tailored solutions, Rotary Machine Knives assists their customers in optimizing their cutting processes to drive productivity and profitability. The company's team of experienced engineers and technicians offer responsive assistance, ensuring quick resolutions and minimized downtime in case of any issues.Conclusion:Rotary Machine Knives has established itself as a driving force in the cutting technology realm, delivering state-of-the-art solutions that redefine precision and efficiency. With an unwavering commitment to innovation and a comprehensive product portfolio, the company continues to meet the diverse needs of industries worldwide, allowing businesses to elevate their cutting processes to new heights. Through pioneering technology, industry-specific applications, and dedicated customer support, Rotary Machine Knives remains at the forefront of the industry, empowering businesses to excel in their operations.