Quality Flooring Blade Set for All Your Cutting Needs

By:Admin

When it comes to flooring installation, having the right tools is essential to ensure a precise and efficient process. One of the most important tools for cutting flooring materials is a high-quality blade set. A leading company in the industry, {Company Name}, has recently launched a new Flooring Blade Set that is set to revolutionize the way professionals and DIY enthusiasts approach flooring installation projects.

{Company Name} has been a trusted name in the flooring industry for over two decades. Specializing in providing high-quality tools and equipment for flooring installation and maintenance, the company has built a strong reputation for its commitment to innovation and excellence. With a focus on delivering products that are not only reliable and durable but also designed to improve efficiency and precision, {Company Name} has become a go-to source for professionals and enthusiasts alike.

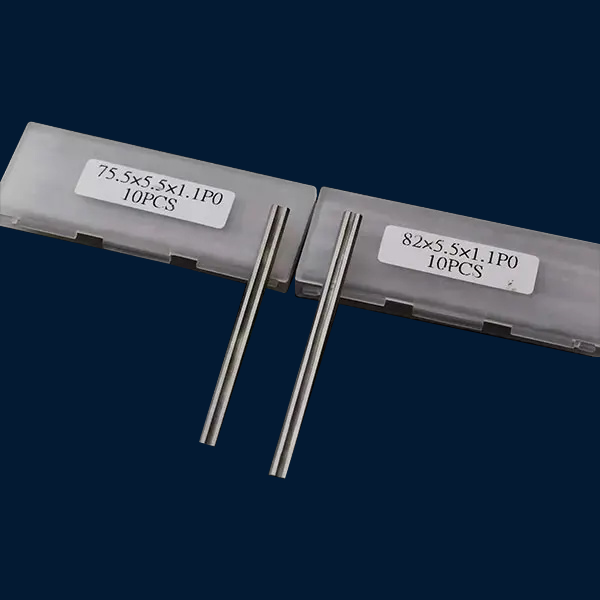

The new Flooring Blade Set is the latest addition to {Company Name}'s extensive range of products. Designed to meet the needs of flooring professionals, the blade set is engineered to deliver exceptional performance in cutting a wide range of flooring materials, including laminate, hardwood, vinyl, and more. The set includes a variety of blade types, each tailored for specific cutting requirements, ensuring that users have the right tool for the job at hand.

One of the standout features of the Flooring Blade Set is its precision-engineered blades. Crafted from high-quality materials, the blades are designed to maintain their sharpness and durability even when used on tough flooring materials. This ensures that users can achieve clean and accurate cuts without the risk of the blades becoming dull or worn out prematurely. The set also includes a convenient storage case, allowing users to keep their blades organized and easily accessible at all times.

In addition to precision, the Flooring Blade Set also prioritizes efficiency. The blades are engineered to minimize dust and debris during cutting, providing a cleaner and safer working environment. This not only improves the user experience but also enhances the overall quality of the flooring installation by reducing the need for extensive clean-up after the cutting process.

The launch of the Flooring Blade Set reflects {Company Name}'s ongoing commitment to meeting the evolving needs of its customers. By delivering a product that combines precision, durability, and efficiency, the company continues to set new standards in the flooring industry. As a trusted partner for professionals and enthusiasts, {Company Name} is dedicated to providing the tools and support that enable its customers to achieve outstanding results in their flooring projects.

With the new Flooring Blade Set, {Company Name} is poised to empower professionals and enthusiasts with a tool that not only simplifies the cutting process but also elevates the overall quality of flooring installations. By equipping users with high-performance blades that are designed to exceed expectations, {Company Name} is reinforcing its position as a leader in the industry, driving progress and innovation with every product it introduces.

As the demand for high-quality tools and equipment continues to grow, {Company Name} remains at the forefront of the industry, consistently delivering solutions that empower its customers to excel in their craft. With the launch of the Flooring Blade Set, the company is once again demonstrating its dedication to elevating standards and setting new benchmarks for excellence in flooring installation.

In conclusion, the new Flooring Blade Set from {Company Name} is set to make a significant impact in the flooring industry. With its focus on precision, durability, and efficiency, the blade set is poised to become an essential tool for professionals and enthusiasts alike, enabling them to achieve outstanding results in their flooring projects. As {Company Name} continues to innovate and set new standards, it reaffirms its position as a true leader in the industry, driving progress and empowering its customers to reach new heights of success.

Company News & Blog

High-Performance Circular Cutters Made from Carbide

Carbide Circular Cutters: The Cutting Edge of Precision ManufacturingWhen it comes to precision cutting, the quality of the tool is just as important as the skill of the operator. For this reason, many businesses rely on Carbide Circular Cutters to meet their high standards of accuracy and efficiency. Whether used in industrial manufacturing or home workshops, these cutting-edge tools offer a level of precision that is unmatched by traditional cutting methods.One of the leading providers of Carbide Circular Cutters is {Company Name}. With over {Number of Years} years of experience in the industry, this company has established a reputation for delivering high-quality cutting tools to businesses of all sizes. Their Carbide Circular Cutters are specifically designed to meet the needs of the most demanding cutting applications, providing a reliable and efficient solution for businesses in a variety of industries.So, what makes Carbide Circular Cutters so special? First and foremost, these cutting tools are made from high-quality carbide materials, which offer superior hardness and resistance to wear and tear. This means that they can withstand the high pressures and temperatures associated with precision cutting, ensuring that they remain sharp and effective for longer periods of time than traditional cutting tools.In addition to their durability, Carbide Circular Cutters also offer exceptional precision and accuracy. Unlike traditional cutting methods, which rely on manual tools like saws and cutters, Carbide Circular Cutters are designed to handle even the most complex cutting tasks with ease. They can be programmed to cut with incredibly fine tolerances, making them an ideal solution for businesses that require precise and accurate cuts on a regular basis.So, what types of businesses and industries can benefit from Carbide Circular Cutters? The answer is almost any industry that requires precise and accurate cutting. For example, they are ideal for use in the automotive, aerospace, and medical industries, where precision and accuracy are critical to success. They are also commonly used in the manufacturing of electronics, plastics, and metals, as well as in woodworking and construction.One of the key benefits of Carbide Circular Cutters is that they can be customized to meet the unique needs of each business. Whether a company requires a specific cutting diameter, depth of cut, or shape, these cutting tools can be tailored to meet those needs. This means that businesses can achieve a higher level of precision and efficiency than they would with traditional, off-the-shelf cutting tools.In addition to their customization options, Carbide Circular Cutters are also incredibly versatile. They can be used on a wide range of materials, including steel, aluminum, plastic, and even wood. This versatility makes them an ideal solution for businesses that work with multiple materials or require a cutting tool that can handle a variety of cutting tasks.At {Company Name}, the team of experts are dedicated to helping businesses achieve the highest level of precision and accuracy in their cutting applications. They understand that every business has unique needs and requirements, which is why they offer a range of Carbide Circular Cutters that can be customized to meet those needs. With their industry-leading experience and expertise, they are able to provide businesses with a cutting solution that is second to none in terms of quality and performance.In conclusion, Carbide Circular Cutters are a cutting-edge solution for businesses that require precision, accuracy, and efficiency in their cutting applications. With their durability, versatility, and customization options, these cutting tools offer a level of performance that is unmatched by traditional cutting tools. The team at {Company Name} is dedicated to delivering the highest quality Carbide Circular Cutters to businesses of all sizes, helping them to achieve their goals and exceed their expectations in precision manufacturing.

Corrugated Board Slitter: Latest News and Updates

BHS Corrugated Sets New Standards for Efficiency and Innovation in the Packaging IndustryIn the fast-paced world of packaging and manufacturing, efficiency and innovation are key drivers of success. As companies strive to meet the demands of the market and stay ahead of the competition, the need for cutting-edge technology and equipment has never been greater. That's why BHS Corrugated, a leading provider of solutions for the corrugated board industry, has once again raised the bar with its latest offering - the corrugated board slitter.With a long history of providing high-quality, reliable equipment for the packaging industry, BHS Corrugated has built a reputation for excellence. The company has consistently demonstrated its commitment to innovation, investing in research and development to create state-of-the-art solutions that meet the evolving needs of its customers. This commitment is evident in the new corrugated board slitter, which represents a significant leap forward in efficiency, productivity, and performance.The new slitter sets itself apart with its advanced features and capabilities, designed to streamline the production process and maximize output. Equipped with cutting-edge technology, the slitter offers unmatched precision, accuracy, and speed, allowing manufacturers to achieve higher levels of efficiency and consistency in their operations. The machine's innovative design and functionality make it an invaluable asset for companies looking to optimize their production processes and stay competitive in the rapidly changing market.One of the most impressive aspects of the new slitter is its versatility. It is capable of handling a wide range of materials and specifications, making it suitable for a diverse array of applications. Whether it's dealing with different types of corrugated board, varying widths, or specific configurations, the slitter is up to the task, ensuring that manufacturers can meet their customers' requirements with ease and confidence. This flexibility is a game-changer for companies that need to adapt to different production demands and maintain a high level of agility in their operations.In addition to its cutting-edge technology and versatility, the slitter is also designed with user-friendliness in mind. Its intuitive interface and controls make it easy to operate and maintain, minimizing downtime and optimizing productivity. With user-friendly features and built-in safety measures, the slitter empowers operators to work efficiently and safely, contributing to a positive work environment and overall satisfaction.The introduction of the new corrugated board slitter is a testament to BHS Corrugated's ongoing commitment to innovation and customer satisfaction. By delivering a product that combines cutting-edge technology with practical functionality, the company is once again setting new standards for excellence in the packaging industry. As manufacturers increasingly seek solutions that can help them navigate the challenges of a dynamic market, BHS Corrugated remains a trusted partner, offering reliable, high-performance equipment that helps businesses thrive in a competitive landscape.As the packaging industry continues to evolve, BHS Corrugated is dedicated to staying at the forefront of innovation, providing its customers with the tools and support they need to succeed. With the new corrugated board slitter, the company is empowering manufacturers to enhance their capabilities, improve their efficiency, and elevate their performance. As a result, BHS Corrugated continues to be a driving force in shaping the future of the packaging industry, creating opportunities for growth and success for businesses around the world.

High-Quality Wood Shredder Knife: The Ultimate Guide

Wood Shredder Knife: A Key Component for Efficient Wood ProcessingWood processing and recycling industries rely on the efficiency and reliability of their equipment to maintain a smooth operation. One crucial component that plays a significant role in the wood recycling process is the wood shredder knife. This essential tool is essential for ensuring the successful and efficient shredding of wood materials, and it has become an integral part of the wood processing industry.{Company Name}, a leading manufacturer of industrial knives and blades, has been at the forefront of producing high-quality wood shredder knives for wood processing and recycling industries. With decades of experience and a commitment to innovation, {Company Name} has established itself as a trusted provider of cutting-edge solutions for various industrial applications.The wood shredder knives produced by {Company Name} are designed to meet the specific needs of wood processing and recycling facilities. These knives are crafted using premium quality materials and state-of-the-art manufacturing processes to ensure their durability, sharpness, and overall performance. With a focus on precision and attention to detail, {Company Name} strives to deliver wood shredder knives that exceed industry standards and meet the demands of the most challenging wood shredding applications.One of the key advantages of {Company Name}'s wood shredder knives is their ability to effectively and efficiently process a wide range of wood materials. Whether it's hardwood, softwood, or engineered wood products, these knives are engineered to deliver consistent and reliable performance, allowing wood processing facilities to achieve optimal results in their operations.Furthermore, {Company Name} offers a range of customization options for its wood shredder knives, allowing customers to tailor the knives to their specific wood shredding requirements. Whether it's a particular blade profile, edge geometry, or surface treatment, {Company Name} works closely with its customers to develop custom solutions that address their unique wood processing needs.In addition to their exceptional quality, {Company Name}'s wood shredder knives are backed by a team of experts who provide comprehensive technical support and assistance to customers. From selecting the right knife for a specific application to offering maintenance and sharpening services, {Company Name} is committed to ensuring that its customers get the most out of their wood shredder knives.As sustainability and environmental responsibility become increasingly important in the wood processing industry, {Company Name} also offers eco-friendly and energy-efficient wood shredder knives. These knives are designed to minimize waste, reduce energy consumption, and optimize the overall wood recycling process, making them a valuable asset for organizations that prioritize environmental stewardship.With a focus on continuous improvement and customer satisfaction, {Company Name} remains dedicated to pushing the boundaries of wood shredder knife technology. By investing in research and development, embracing new manufacturing techniques, and collaborating with industry partners, {Company Name} is poised to remain a leader in providing innovative solutions for the wood processing and recycling industry.As the demand for efficient wood processing and recycling solutions continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its high-performance wood shredder knives. With a proven track record of excellence and a commitment to customer success, {Company Name} continues to set the standard for quality and reliability in the wood processing and recycling sector.

Newly Released Corrugated Paper Blades: A Breakthrough Technology for Enhanced Cutting Efficiency

Title: Innovation Driven Efficiency: Introducing Corrugated Paper Blades by [Company]Introduction:[Company], a leading player in the manufacturing industry, has unveiled a breakthrough product: Corrugated Paper Blades. With a proven commitment to innovation and a strong focus on customer satisfaction, [Company] has once again set an exemplary standard in the market. This news piece will delve into the features, benefits, and potential impacts of Corrugated Paper Blades by [Company].I. Overview of Corrugated Paper Blades:Corrugated Paper Blades are a pioneering solution developed by [Company] to enhance the efficiency and precision in cutting corrugated paper, one of the most commonly used materials in the packaging industry. These blades are specifically designed to meet the demanding requirements of corrugated paper production lines, offering improved durability, longevity, and cutting accuracy. With their enhanced design, Corrugated Paper Blades aim to revolutionize the manufacturing landscape for various industries reliant on corrugated packaging.II. Features and Benefits of Corrugated Paper Blades:a. Enhanced Durability: The Corrugated Paper Blades by [Company] are manufactured using cutting-edge materials and state-of-the-art technology, ensuring increased durability and prolonged lifespan. This feature helps reduce downtime due to blade replacements, optimizing operational efficiency and cost-effectiveness for businesses.b. Precise Cutting: The design of Corrugated Paper Blades incorporates advanced cutting edge geometries and sharpening techniques, resulting in unparalleled precision during the cutting process. This not only enhances the overall quality of the finished products but also minimizes production waste, leading to improved profitability for manufacturers.c. Customizability: Recognizing the diverse needs of its customers, [Company] offers Corrugated Paper Blades in various sizes and configurations. This flexibility allows businesses to find the perfect fit for their specific corrugated paper cutting requirements, further optimizing their operations.d. Eco-Friendly Solution: In line with [Company]'s commitment to sustainability, Corrugated Paper Blades are manufactured using eco-friendly materials and production processes. This eco-conscious approach ensures that end-users can reduce their carbon footprint while benefiting from the product's exceptional performance.III. Impact on Industries:The introduction of Corrugated Paper Blades by [Company] is expected to have a significant positive impact on various industries, particularly those heavily reliant on corrugated packaging. Some of the key effects include:a. Improved Productivity: By providing accurate and efficient cutting, Corrugated Paper Blades will streamline production processes, which in turn will boost overall productivity. Manufacturers will witness a reduction in material wastage, downtime, and rework, leading to higher output and profitability.b. Enhanced Quality Control: With precision cutting capabilities, Corrugated Paper Blades will contribute to the consistent production of high-quality corrugated paper products. This will strengthen the brand reputation of businesses and improve customer satisfaction.c. Cost Optimization: Corrugated Paper Blades' enhanced durability and longer lifespan contribute to reduced maintenance costs and fewer blade replacements. Consequently, businesses can allocate their resources more effectively and invest in other growth opportunities.d. Sustainability: The adoption of Corrugated Paper Blades aligns with the growing global trend of sustainability in manufacturing. By using eco-friendly materials and production processes, businesses can improve their environmental credentials and cater to increasingly conscious consumer demands.Conclusion:[Company]'s innovative Corrugated Paper Blades demonstrate their commitment to driving efficiency and customer satisfaction. With enhanced durability, cutting precision, and eco-friendly features, these blades offer numerous benefits to manufacturers relying on corrugated packaging. By embracing this cutting-edge solution, businesses can optimize their operations, enhance productivity, deliver high-quality products, and contribute to a sustainable future.

High-Quality Slitting Blades for Lithium Battery Chips: A Guide to Manufacturers and Suppliers

and Lithium Battery Chip Slitting Knife throughout the content.The demand for advanced lithium batteries is surging worldwide. Lithium-ion batteries, in particular, are popular among electronic device manufacturers due to their high efficiency, durability, and long shelf life. However, the lithium-ion battery production process is not without its challenges. One of the critical steps in the production process is chip slitting. Chip slitting involves cutting the anode and cathode material into thin strips to divide the electrodes. For this process, battery manufacturers require reliable and high-quality lithium battery chip slitting blades/knives.There are several manufacturers of lithium battery chip slitting blades/knives in China. These blades/knives are available in various sizes, shapes, and materials. The most commonly used materials for these blades/knives are tungsten carbide, ceramic, and diamond. Each material has its unique characteristics and benefits.Tungsten Carbide Blades/KnivesTungsten carbide blades/knives are the most widely used type of lithium battery chip slitting blades/knives. These blades/knives are made of tungsten carbide, a hard and durable material that can withstand high levels of wear and tear. Tungsten carbide blades/knives are ideal for cutting through thick and hard materials, making them ideal for lithium battery chip slitting.Ceramic Blades/KnivesCeramic blades/knives are also popular for lithium battery chip slitting. These blades/knives are made of zirconia or alumina, which are highly resistant to wear and corrosion. Ceramic blades/knives are lightweight, making them easy to handle, and they generate less heat during the cutting process. These characteristics make ceramic blades/knives ideal for high-precision cutting applications.Diamond Blades/KnivesDiamond blades/knives are the most expensive type of lithium battery chip slitting blades/knives, but they are also the most durable. These blades/knives are made of a diamond-coated carbide material, which can easily cut through hard and abrasive materials. Diamond blades/knives are ideal for cutting through materials like silicon anodes, which are challenging to cut with other types of blades/knives.ConclusionChoosing the right type of lithium battery chip slitting blades/knives is critical to the efficiency and production quality of a lithium-ion battery. Tungsten carbide, ceramic, and diamond blades/knives are the most popular materials used for this purpose. Each material has its advantages and disadvantages, so it is essential to choose the right blade/knife based on the specific needs of the manufacturer. Regardless of the type of blade/knife selected, it is essential to work with reliable and high-quality manufacturers who use advanced production techniques to ensure consistent and accurate cuts. Battery slitting blade and lithium battery chip slitting knife are essential tools in the production process of lithium-ion batteries, and choosing the right one can make the difference between a successful and failed project.

Exploring the Thrilling World of Black-Clad Heroes

Glorious Trash: Good Guys Wear Black - The Chuck Norris Tie-In You Need to ReadChuck Norris has been a cultural icon for several decades now, and his larger-than-life persona has continued to inspire countless fans around the world. The former martial arts champion turned movie star has appeared in several iconic films throughout his career, and one of the most memorable ones has to be Good Guys Wear Black.The movie, which was released in 1978, was a classic action flick that showcased Norris' impressive skills as a martial artist and actor. It was also turned into a novel by Max Franklin, and the tie-in edition remains a must-read for any Chuck Norris fan.So, what makes Good Guys Wear Black such a great read? Well, for starters, the book offers a more in-depth look into the story and characters than the movie could. The novelization fleshes out the plot and gives readers a more nuanced understanding of the events that unfold.Moreover, the book is written in a style that perfectly captures the tone and pace of the movie. It's fast-paced, action-packed, and filled with witty one-liners that are quintessential Norris. The writing is also surprisingly well-crafted, which makes for an engaging and enjoyable reading experience.However, the real highlight of Good Guys Wear Black is undoubtedly Chuck Norris' performance. The book manages to capture the essence of his character and his unique fighting style, making it a must-read for any fan of his work. Whether you're a long-time Chuck Norris aficionado or new to the world of martial arts movies, this tie-in edition is sure to impress.Another exciting aspect of Good Guys Wear Black is the fight scenes. In particular, Norris' use of a "good wear life blade" is a thrilling addition that adds an extra layer of excitement to the action sequences. The weapon is described in detail in the book, making it a memorable feature of the story.In conclusion, if you're a fan of Chuck Norris or just love a good, action-packed read, Good Guys Wear Black is a must-have addition to your bookshelf. The tie-in edition perfectly captures the essence of the movie and offers readers an engaging and enjoyable reading experience. So, go ahead and add this glorious trash to your collection - you won't regret it!

New Study Finds Majority of Beer Drinkers Prefer Craft Over Traditional" could be rewritten as "Majority of Beer Drinkers Favor Craft Beers in New Study".

[News Title]Cutting-Edge Cutter Technology Revolutionizing Industries: A Comprehensive Look into the Innovations of [Company][News Introduction]In today's rapidly evolving technological landscape, [Company] has been making significant waves with its groundbreaking cutter technology. Pioneering in several industries, [Company] has successfully transformed the way companies and individuals approach cutting tasks. With their advanced innovations, they have not only simplified and expedited operations but also ensured heightened precision and safety. Let's delve deeper into the revolutionary developments brought about by [Company] and the significant impact they have had on various sectors.[Company Background]Established in [Year], [Company] has spent years at the forefront of research and development to create cutting-edge cutter solutions. The company's vision is to reshape industries by providing cutting technology that surpasses existing benchmarks, revolutionizing efficiency, and enhancing operational safety. Utilizing a team of expert engineers and adopting state-of-the-art manufacturing techniques, [Company] has consistently pushed boundaries to deliver cutting solutions that cater to a wide range of applications.[Segment 1: Industrial and Manufacturing Sector]With their innovative cutter technology, [Company] has significantly transformed the industrial and manufacturing sector. By leveraging precision laser cutting, their equipment has enabled manufacturers to achieve unparalleled accuracy and efficiency in their production processes. These advanced solutions have allowed companies to minimize material waste and streamline operations, resulting in cost savings and improved productivity. Additionally, [Company's] cutting tools are designed to integrate seamlessly with industrial automation systems, further enhancing overall productivity.[Segment 2: Medical and Healthcare Sector]Recognizing the unique requirements of the medical and healthcare sector, [Company] has developed cutting solutions that are reshaping surgical procedures. By incorporating robotics and artificial intelligence, their cutters have revolutionized precision and safety in the operating room. Surgeons can now rely on [Company's] technology to perform intricate surgeries with unparalleled accuracy, resulting in improved patient outcomes and reduced recovery periods. Furthermore, the incorporation of advanced safety features ensures minimal risk during procedures, guaranteeing the well-being of both patients and medical professionals.[Segment 3: Construction and Architecture Sector]In the construction and architecture sector, [Company] has introduced cutter technology that has transformed the way projects are executed. With their efficient and high-precision tools, contractors can now tackle complex cutting tasks with ease. This has vastly improved the accuracy of project execution, leading to optimal results and reducing instances of rework. Moreover, [Company's] wide range of cutting solutions caters to different construction materials, allowing contractors to meet diverse project requirements while ensuring timeliness and cost-effectiveness.[Segment 4: Arts and Crafts]Not limited to industrial applications, [Company] has also made a significant impact in the arts and crafts community. By offering cutting tools that are user-friendly and versatile, artists and crafters can bring their intricate designs to life. [Company's] cutters are equipped with intuitive software, allowing creators to effortlessly design and execute complex patterns. This advancement has not only provided artists with enhanced creative freedom but has also accelerated the production of intricate and precise crafts.[Segment 5: Sustainable Manufacturing]In line with growing concerns for environmental sustainability, [Company] has integrated eco-friendly practices into their manufacturing processes. Through the use of energy-efficient technologies and sustainable materials, [Company's] cutters contribute to minimizing carbon footprints. Their commitment to sustainability extends beyond their manufacturing practices, as they continuously strive to develop techniques that promote recycling and waste reduction in various industries.[Conclusion]With their groundbreaking cutter technology, [Company] has revolutionized various industries, from manufacturing and healthcare to construction and arts. Through continuous innovation, the company has positioned itself as a global leader in advanced and efficient cutting solutions. As [Company] continues to push boundaries, the future of cutting technology appears full of promise, with further advancements poised to reshape industries and unlock new possibilities across multiple sectors.

Discover the Latest Insights on Tobacco Filter Rods Slitter Knives

Tobacco Filter Rods Slitter Knives: Revolutionizing Efficiency in Tobacco ProductionTobacco production has always been an industry that demands precision and efficiency. With the increasing demand for cigarettes across the globe, manufacturers constantly search for innovative solutions to improve their production processes. Recently, a pioneering company has launched a groundbreaking tool that is set to revolutionize the tobacco industry – the Tobacco Filter Rods Slitter Knives.Introducing a Perfect Harmony of Quality and EfficiencyThe Tobacco Filter Rods Slitter Knives, developed by a leading manufacturer in the field, are designed to offer a perfect harmony of quality and efficiency in the tobacco production process. With their state-of-the-art technology and meticulous craftsmanship, these knives are poised to transform the way filter rods are slit, resulting in significant improvements in production speed and accuracy.The company behind this groundbreaking invention has been a trailblazer in the tobacco machinery industry for over two decades. They have consistently delivered cutting-edge solutions that have helped tobacco companies streamline their production processes and enhance their product quality. Their deep understanding of the tobacco industry's requirements has enabled them to create tools that not only meet industry standards but also exceed expectations.Enhancing Efficiency and PrecisionThe Tobacco Filter Rods Slitter Knives are specifically designed to enhance the efficiency and precision of the tobacco production process. These knives are crafted with the highest quality materials, ensuring durability and longevity, even under demanding operating conditions. The company utilizes advanced manufacturing techniques and stringent quality control measures to guarantee exceptional performance.One of the key features of these knives is their ability to achieve precise slitting of filter rods. The intricate design and sharpness of the blades enable manufacturers to achieve consistent and accurate cuts, ensuring that each filter rod meets the desired specifications. This feature not only reduces waste in the production line but also ensures that the final product is of the highest quality.Furthermore, the Tobacco Filter Rods Slitter Knives are designed for easy installation and maintenance. The company provides comprehensive user manuals and technical support to assist customers in incorporating these knives seamlessly into their production systems. This user-friendly approach ensures that tobacco manufacturers can swiftly integrate this innovative tool into their existing processes, without causing disruptions or delays.Advancing the Tobacco IndustryThe introduction of the Tobacco Filter Rods Slitter Knives marks a significant milestone in the tobacco industry. This groundbreaking tool is set to revolutionize the way filter rods are slit, ultimately improving productivity, reducing waste, and enhancing the overall efficiency of tobacco production. By embracing this cutting-edge technology, manufacturers can stay ahead of the competition and meet the ever-growing demands of the tobacco market.With its commitment to innovation and continuous improvement, the company behind the Tobacco Filter Rods Slitter Knives ensures that its customers benefit from the latest advancements in the industry. They continue to invest in research and development, striving to create new solutions that address the evolving needs and challenges of tobacco manufacturers worldwide.ConclusionThe Tobacco Filter Rods Slitter Knives represent a game-changer for the tobacco industry, promising to streamline production processes and elevate product quality to new heights. As this revolutionary tool makes its mark in the market, tobacco manufacturers can look forward to improved efficiency, increased profitability, and enhanced customer satisfaction. With its combination of precision, durability, and ease of use, these knives undoubtedly have the potential to reshape the future of the tobacco production industry.

The Versatile and Efficient Three-Hole Knife: A Must-Have Kitchen Tool

Smiths Ltd is pleased to announce the release of its latest cutting-edge kitchen tool, the 3 Hole Knife. This innovative knife is designed to improve efficiency and precision in the kitchen, making it an essential addition to any home cook or professional chef's arsenal. The 3 Hole Knife features a unique design with three precision-cut holes along the blade, which allows for smoother cutting and slicing of a wide range of ingredients. Whether you're chopping vegetables, slicing meat, or dicing herbs, this knife offers unparalleled control and accuracy, making it an ideal choice for any kitchen task."We are thrilled to introduce the 3 Hole Knife to the market," said John Smith, CEO of Smiths Ltd. "We believe that this knife will revolutionize the way people approach food preparation, providing a level of precision and efficiency that has never been seen before."In addition to its innovative design, the 3 Hole Knife is made from high-quality stainless steel, ensuring durability and longevity. The blade is also carefully balanced for a comfortable and ergonomic grip, making it easy to handle for extended periods of time. Whether you're a professional chef working in a fast-paced restaurant kitchen or a home cook preparing meals for your family, the 3 Hole Knife is designed to meet the needs of all users."We have conducted extensive research and development to ensure that the 3 Hole Knife meets the highest standards of quality and performance," said Smith. "We are confident that this knife will exceed our customers' expectations and become an indispensable tool in their kitchens."The 3 Hole Knife is the latest addition to Smiths Ltd's extensive range of kitchen tools and accessories, which are known for their superior quality and innovation. The company has been a leading manufacturer and supplier in the culinary industry for over 50 years, earning a reputation for excellence and reliability."Our mission at Smiths Ltd is to provide our customers with the tools and equipment they need to succeed in the kitchen," said Smith. "We are committed to continuous innovation and improvement, and the 3 Hole Knife is a testament to that dedication."The 3 Hole Knife is now available for purchase online and at select retailers. With its advanced design and superior performance, this knife is expected to become a must-have item for anyone who takes their cooking seriously. Whether you're a professional chef looking for the latest in kitchen technology or a home cook seeking to elevate your culinary skills, the 3 Hole Knife is a game-changer that will revolutionize the way you approach food preparation."We are confident that the 3 Hole Knife will make a significant impact in the culinary world," said Smith. "We are excited to see how this innovative tool will empower chefs and home cooks alike to take their cooking to new heights." For more information about the 3 Hole Knife and other products from Smiths Ltd, please visit their website or contact their customer service team. With a commitment to quality, innovation, and customer satisfaction, Smiths Ltd continues to be a driving force in the culinary industry, providing professional-grade tools for chefs and home cooks around the world.

Top 10 Best Quality Blades in 2021

Blades, a leading company in the field of outdoor equipment, has recently unveiled their latest product line designed to revolutionize the way outdoor enthusiasts experience the wilderness. The company, known for its commitment to durability, reliability, and innovation, has been a trusted name in the industry for over a decade. With the introduction of their new line of blades, they are raising the bar once again.The Blades team has been hard at work, leveraging the latest technology and design principles to create blades that are not only functional and durable, but also lightweight and versatile. Their team of experts has poured countless hours into research and development, ensuring that each blade meets the high standards that the company has become known for.One of the key features of their new line of blades is the use of high-quality materials, such as high-carbon stainless steel and titanium, to ensure that they can withstand even the toughest outdoor conditions. This means that outdoor enthusiasts can rely on their Blades products to perform when it matters most, whether they are hiking through rugged terrain, camping in the wilderness, or simply tackling everyday tasks.In addition to their commitment to quality, Blades has also focused on creating blades that are versatile and practical. Each blade in their new line is designed to serve a variety of purposes, from cutting and chopping to slicing and dicing. This means that outdoor enthusiasts can carry just one blade with them, rather than a whole arsenal of tools, making it easier and more convenient to enjoy their outdoor adventures.Furthermore, Blades has taken user experience into account when designing their new line of blades. Each blade is ergonomically designed for maximum comfort and control, making it easier and safer to use, even in challenging conditions. Additionally, they have incorporated features such as easy-to-grip handles and safety locks to ensure that their blades are user-friendly and reliable.The unveiling of the new line of blades from Blades has been met with enthusiasm from outdoor enthusiasts and industry professionals alike. Many have praised the company for their commitment to quality and innovation, and have expressed excitement about the prospect of getting their hands on these new products. With the company's track record of success and their dedication to pushing the boundaries of what is possible in outdoor equipment, it is no surprise that the release of their new line of blades has generated significant buzz.Blades has also made it clear that this is just the beginning. They have hinted at additional products and innovations in the pipeline, suggesting that there is much more to come from this forward-thinking company. With their continued dedication to excellence, it is clear that Blades will remain a dominant force in the outdoor equipment industry for years to come.In conclusion, the unveiling of Blades' new line of blades represents a significant milestone for the company and the outdoor equipment industry as a whole. With a focus on quality, versatility, and user experience, these blades are set to redefine the way outdoor enthusiasts approach their adventures. As Blades continues to push the boundaries of innovation, it is clear that they will remain a leading force in the industry for years to come.