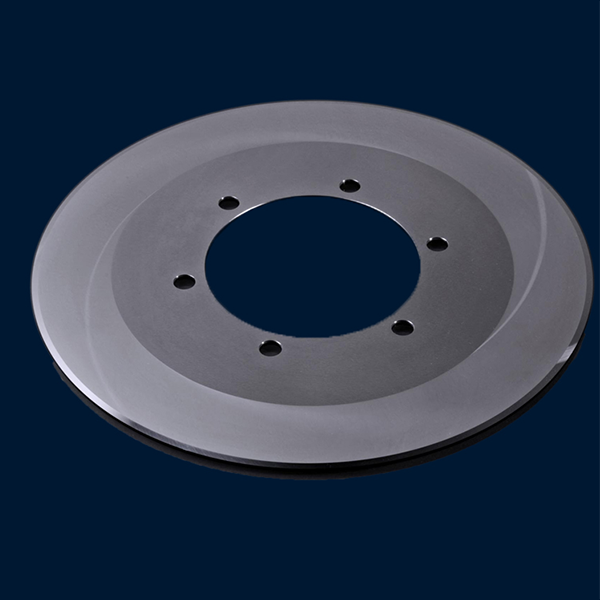

High-Quality Toothed Cutting Blade for Efficient Cutting

By:Admin

[Company Name], a leading manufacturer of industrial cutting tools and solutions, has recently launched its newest addition to their product line - the Toothed Cutting Blade. This state-of-the-art blade is designed to provide exceptional cutting performance and accuracy for a wide range of industrial applications.

The Toothed Cutting Blade is the result of years of research and development by [Company Name]'s team of expert engineers and designers. The company's commitment to innovation and excellence is evident in the precision engineering and high-quality materials used in the production of this cutting-edge tool.

With its unique toothed design, the Toothed Cutting Blade offers unparalleled cutting efficiency and versatility. It is capable of cutting through a variety of materials, including metal, plastic, wood, and composite substances, with utmost precision and speed. The toothed design of the blade ensures a clean and smooth cut, making it the ideal choice for industries where precision and accuracy are of utmost importance.

"We are extremely proud to introduce the Toothed Cutting Blade to the market," said [Company Name]'s spokesperson. "This innovative tool is a game-changer for industries that rely on high-quality cutting solutions. Whether it's for metal fabrication, woodworking, or general industrial cutting applications, the Toothed Cutting Blade delivers exceptional performance and reliability."

In addition to its superior cutting performance, the Toothed Cutting Blade is also designed with user convenience and safety in mind. The blade is equipped with advanced safety features to minimize the risk of accidents and ensure the protection of the user. Its ergonomic design and easy-to-use functionality make it a valuable tool for professionals in various industries.

[Company Name] has built a solid reputation for delivering cutting-edge solutions that meet the evolving needs of the industrial sector. The company's commitment to quality and innovation has earned them the trust and loyalty of countless customers worldwide. With the introduction of the Toothed Cutting Blade, [Company Name] further solidifies its position as a leader in the industry.

The Toothed Cutting Blade is now available for purchase through [Company Name]'s extensive network of distributors and partners. The company is also offering comprehensive support and technical assistance to ensure that customers can maximize the potential of this innovative cutting tool.

As industries continue to evolve and demand more advanced cutting solutions, [Company Name] remains dedicated to pushing the boundaries of innovation and setting new standards for excellence in the field of industrial cutting technology. The launch of the Toothed Cutting Blade is a testament to the company's unwavering commitment to delivering high-quality, high-performance tools that empower businesses to thrive in the modern industrial landscape.

For more information about the Toothed Cutting Blade and other cutting solutions offered by [Company Name], please visit their official website or contact their customer service team. The company looks forward to serving the diverse needs of industries with its latest innovation and continuing to be a trusted partner for cutting-edge solutions.

Company News & Blog

Top Paint Scraper for Efficient and Easy Paint Removal

Richards Paint Scraper (name changed), a leading manufacturer in the paint and hardware industry, has recently unveiled its latest innovation in paint removal tools. The company, which has been in operation for over two decades, is known for its high-quality products and dedication to meeting the needs of professionals and DIY enthusiasts alike.The new paint scraper is designed to make the paint removal process more efficient and less labor-intensive. It features a durable stainless steel blade that is able to effectively scrape away layers of paint without causing damage to the underlying surface. Additionally, the scraper is equipped with a comfortable, ergonomic handle that allows for prolonged use without causing strain or discomfort to the user."We are thrilled to introduce our newest paint scraper to the market," said James Richards, the CEO of Richards Paint Scraper. "Our team has worked tirelessly to develop a tool that not only simplifies the paint removal process, but also meets the high standards of quality and performance that our customers have come to expect from us."In addition to its superior functionality, the paint scraper is also designed with safety in mind. The blade is securely attached to the handle, reducing the risk of accidents or injuries during use. Furthermore, the scraper is equipped with a blade cover that can be easily attached when the tool is not in use, providing an extra layer of protection for both the user and the blade itself.The paint scraper is suitable for use on a variety of surfaces, including wood, metal, and concrete. This versatility makes it an ideal tool for a wide range of painting and renovation projects, whether in a professional capacity or for personal use.Richards Paint Scraper has a long history of providing top-notch products and unparalleled customer service. The company is committed to ensuring that its customers have access to the best tools and equipment for their projects, and the new paint scraper is no exception."Our customers are at the forefront of everything we do," said Richards. "We are constantly striving to improve and innovate in order to better serve their needs. With the launch of our new paint scraper, we are confident that we are offering a solution that will make the paint removal process easier and more efficient for everyone."In addition to its commitment to quality and innovation, Richards Paint Scraper is also dedicated to sustainability and environmental responsibility. The company utilizes eco-friendly manufacturing processes and materials whenever possible, and it is continually seeking new ways to reduce its carbon footprint and minimize waste."Our mission goes beyond providing excellent products," Richards explained. "We want to ensure that our business practices have a positive impact on the world around us. By prioritizing sustainability and environmental responsibility, we are working to create a better future for our customers and the planet."With the introduction of its latest paint scraper, Richards Paint Scraper continues to solidify its position as a leader in the paint and hardware industry. The company's unwavering commitment to quality, innovation, and environmental responsibility sets it apart as a trusted and reliable source for professional-grade tools and equipment.The new paint scraper is now available for purchase through Richards Paint Scraper's website and select retailers. As the company looks toward the future, it remains dedicated to exceeding the expectations of its customers and providing them with the tools they need to bring their projects to life.

High-Quality Doctor Blade for Paper Making Machines at a Competitive Price

Doctor Blade for Paper Making Machine: Leizhan Paper Machinery Co., Ltd Offers Superior Quality, High Performance and Efficient Doctor BladesLeizhan Paper Machinery Co., Ltd is a leading manufacturer and supplier of paper making machinery and equipment based in China. The company has been providing high-quality, efficient, and cost-effective solutions to paper mills' requirements across the globe. Leizhan Paper Machinery Co., Ltd understands the importance of precision and accuracy in the paper making process. That is why the company provides top-quality doctor blades to the customers to ensure maximum efficiency and productivity.Doctor blades are a crucial component of the paper making machine. The doctor blade is responsible for removing excess material or fibers from the surface of the paper roll. The process helps to ensure that the paper produced is of high quality and consistent. The quality of doctor blades determines the paper's quality and production efficiency. Leizhan Paper Machinery Co., Ltd provides doctor blades that meet the highest standards of quality. The doctor blades are made of high-quality materials, ensuring that they are durable and long-lasting.Leizhan Paper Machinery Co., Ltd offers doctor blades that can be used with a wide range of paper and board grades, including coated, uncoated, newsprint, and tissue paper. The doctor blades are designed to meet the specific needs of each paper mill, ensuring the highest level of precision and accuracy. At Leizhan Paper Machinery Co., Ltd, we understand that every paper mill has unique requirements and specifications. That's why our team of experts works closely with each customer to understand their needs and develop tailored solutions that meet their specific requirements.Leizhan Paper Machinery Co., Ltd has invested heavily in research and development to improve the performance and efficiency of doctor blades. The company has employed cutting-edge technologies to produce doctor blades that offer unmatched performance, quality, and durability. The doctor blades are designed to reduce wear and tear on the paper machine's components, resulting in a longer lifespan and lower maintenance costs.Leizhan Paper Machinery Co., Ltd's doctor blades are packed with features that make them stand out in the market. The blades are made of high-quality materials that are resistant to wear and tear even under harsh operating conditions. The blades are designed to have a sharp and consistent edge, ensuring that the paper produced is of high quality and consistent. The blades have a smooth and consistent surface that reduces friction and wear on the machine's components.Leizhan Paper Machinery Co., Ltd's doctor blades are highly efficient and can significantly improve the paper mills' overall productivity. The blades have a long lifespan, reducing the need for frequent replacement and maintenance. The blades are easy to install and use, making them an ideal solution for paper mills that want to improve their production efficiency and reduce their operating costs.In conclusion, Leizhan Paper Machinery Co., Ltd is a reputable and reliable supplier of doctor blades for paper making machines. The company offers superior quality, high performance, and efficient doctor blades that meet the highest standards of quality. The company's commitment to research and development has enabled it to produce doctor blades that offer unmatched performance, quality, and durability. If you are looking for doctor blades for your paper making machine, Leizhan Paper Machinery Co., Ltd is the ideal supplier to meet your needs.

New Tapered Blade Design Enhances Bag Cutting Efficiency

Bag Taper Blade – Revolutionizing the Packaging IndustryFor businesses that deal with packaging, finding the most efficient and cost-effective solutions is essential. In recent years, Bag Taper Blade has emerged as a game-changer in the industry. This innovative product makes the process of sealing bags faster, easier, and more precise than ever before. With its exceptional performance, it has become a success story. Bag Taper Blade is a product of {company name}, a reputable manufacturer and distributor of packaging tools and accessories. The company has been providing high-quality solutions to customers for many years. They understand the needs of the packaging industry and are continually looking for ways to upgrade and enhance their product line.The Bag Taper Blade is one such product that the company has developed with a clear understanding of the packaging industry's requirements. This tool is designed to be durable, efficient, and easy to use. It is made of high-quality steel that can withstand heavy usage and endure harsh environments. The blade is also resistant to corrosion, which ensures its longevity and reliability.One of the most notable benefits of Bag Taper Blade is its speed. It can seal bags quickly and effortlessly, averting delays and increasing productivity. This is particularly beneficial for businesses that require high output while maintaining quality standards. The product has been tested and proven to work faster than traditional sealing machines, making it an excellent investment for businesses that prioritize efficiency.Another essential feature of Bag Taper Blade is its precision. The blade is designed to seal bags evenly, preventing any leaks or spillage. This means that businesses can package their products efficiently, ensuring that they maintain quality and integrity during transportation and storage. The precision of the blade also minimizes the risk of waste, which can save money for businesses in the long run.The Bag Taper Blade is also easy to use. It requires minimal training as it is straightforward and user-friendly. The blade is designed to fit onto most sealing machines, making it convenient for businesses that do not want to replace their equipment. The blade's installation process is simple and straightforward, and it can be done without the need for any additional tools.Perhaps one of the most significant advantages of Bag Taper Blade is its versatility. It can be used in a wide range of industries, including food and beverage, agriculture, pharmaceuticals, and more. The product's flexibility provides businesses with a lot of options and the ability to adapt to different packaging needs.In conclusion, the Bag Taper Blade has revolutionized the packaging industry, providing businesses with a cost-effective, efficient, and reliable sealing solution. Its numerous benefits, including speed, precision, ease of use, and versatility, make it a must-have for businesses looking to stay ahead of the curve. With its exceptional performance, Bag Taper Blade has become an industry leader, providing innovative solutions that meet the changing needs of businesses. The Bag Taper Blade is available for purchase online on {company name}'s website. Their support team is always ready to assist in choosing and installing the blade to ensure that businesses experience maximum efficiency and return on investment.

Discover the Efficiency of a Cutting Knife Made from Cardboard

Cardboard Cutting Tool: The Sustainable Solution for Every BusinessEvery business understands the importance of sustainability, not only from an ecological standpoint but also in terms of financial and operational efficiency. The demand for environmentally friendly alternatives to traditional business practices has led to the development of innovative solutions aimed at reducing waste, emissions, and costs. One such solution is the Cardboard Cutting Tool, a sustainable alternative to traditional cutting knives.The Cardboard Cutting Tool is a simple yet powerful tool designed to cut through cardboard, paper, and other fibrous materials. The tool features a durable, high-quality blade that is made from stainless steel and is built to last. The blade is attached to a sturdy handle made from recycled plastic, making the tool lightweight and easy to handle.This cutting tool is ideal for businesses that need to cut cardboard and other materials on a regular basis. It is perfect for packaging companies, shipping warehouses, and other businesses that deal with large volumes of cardboard and paper. Unlike traditional cutting knives, the Cardboard Cutting Tool is designed to be safer and more efficient, reducing the risk of injuries and accidents in the workplace.The Cardboard Cutting Tool is also an eco-friendly solution that helps businesses reduce waste and emissions. It is made from recycled materials, which means that it has a much lower carbon footprint than traditional cutting knives. Additionally, the durable blade means that the tool can be used for a long time, reducing the need for constant replacements and further reducing waste.One company that is leading the way in the production of sustainable cutting tools is {company name}. Founded in {year}, the company has been committed to providing eco-friendly solutions to businesses across a range of industries. With a focus on innovation and sustainability, {company name} has quickly become one of the most trusted names in the industry.Taking inspiration from the ever-increasing demand for sustainable alternatives to traditional business practices, {company name} developed the Cardboard Cutting Tool. The tool has been designed to meet the needs of businesses that want to reduce their environmental impact while maintaining the efficiency and quality of their operations.The Cardboard Cutting Tool is just one example of {company name}'s commitment to sustainability. The company also produces a range of other eco-friendly cutting tools, including recycled plastic knives, biodegradable blades, and more. {Company name} is constantly developing new and innovative products to help businesses reduce their environmental impact, and the Cardboard Cutting Tool is just the beginning.In conclusion, the Cardboard Cutting Tool is a sustainable solution that offers businesses a safer, more efficient, and more eco-friendly alternative to traditional cutting knives. It is the perfect tool for businesses that deal with large volumes of cardboard and paper, and it is made from recycled materials, reducing waste and emissions. With {company name} leading the charge in the development of eco-friendly cutting tools, businesses can be confident that they are investing in a sustainable future.

Industrial Quality Solid Carbide Ball End Insert Knives for CNC Router Bits and Tooling

, CNC Router Bits, Industrial CNC Tooling, Amana Tool, Saw Blades, Shaper Cutters, Boring Bits, Planer and Jointer Knives.If you need to machine materials that are tough, abrasive, or hard to cut effectively, then you need the right tools for the job. Solid carbide insert knives offer several advantages over traditional cutting tools. They can increase your productivity, reduce your downtime, and enhance your cutting performance. At Amana Tool, we offer a wide range of industrial-quality router bits, CNC router bits, saw blades, shaper cutters, boring bits, and planer and jointer knives that meet the needs of any woodworking or manufacturing application.Our Solid Carbide Ball End Insert CNC Replacement Knives are a perfect example of the precision and durability that our products offer. These knives are designed to fit into standard CNC routers and offer superior cutting performance in materials like aluminum, hardwoods, MDF, particle board, and more. They are also ideal for cutting through difficult materials such as plastics, foam, and composites.The Solid Carbide Insert Knives used for these replacement knives are made from premium grade carbide materials that are designed to withstand repeated use and last longer than traditional cutting tools. This industrial-grade material is extremely hard and wear-resistant, which means that it holds its cutting edge longer and can deliver more precise cuts for longer periods of time.These insert knives also offer a significant improvement in cutting performance over traditional cutting tools. The unique design and sharp edge of these knives enable them to slice through materials with ease, without generating excessive heat or friction. This enables you to achieve a smoother, more accurate finish, even on difficult-to-cut materials.Our CNC Router Bits and Industrial CNC Tooling are world-renowned for their quality and precision. They are made with the highest quality materials and manufacturing processes to ensure that they meet the high demands of our industrial customers. Our tools are designed to be easy to use, with a range of sizes and configurations to meet any application.Our Saw Blades are also designed to deliver superior cutting performance in various materials, including hardwoods, softwoods, plastics, and more. Our blades are made from the best quality materials that provide the perfect balance of sharpness, durability, and heat resistance. We offer a broad range of sizes, tooth configurations, and blade types to meet a variety of cutting requirements.Our Shaper Cutters are perfect for producing precise and repeatable cuts on a range of materials. They are made from the highest quality carbide materials, which ensure that they remain sharp and durable even after multiple uses. We offer a wide range of shaper cutter types, including bead, straight, and cove, among others.Our Boring Bits are among the best in the industry, delivering precision drilling and smooth finish even in the toughest materials. They are made from premium quality carbide materials that ensure better cutting speeds and accuracy. We offer a range of boring bit types, such as through-hole bits, hinge boring bits, and dowel drilling bits to meet various applications.Our Planer and Jointer Knives are designed to make your woodworking tasks easy and efficient. They are made from premium quality carbide materials that ensure sharper and more precise cuts every time. We offer a broad range of knives sizes, shapes, and configurations to meet the needs of any woodworker.ConclusionSolid carbide insert knives, CNC router bits, and industrial CNC tooling are essential tools for anyone engaged in woodworking or manufacturing. They offer superior cutting performance, longer life, and greater precision than traditional tools, making them a smart investment for businesses of all sizes. At Amana Tool, we're dedicated to providing the highest quality tools at competitive prices and with unparalleled customer service. So, if you're looking for the best tools for your woodworking and manufacturing needs, look no further than Amana Tool!

Quality Cutting Knives from Reliable Suppliers in China for Global Buyers

In modern times, cutting knives have become an indispensable tool in various manufacturing industries. For instance, industries dealing with textiles, leather, and paper heavily depend on cutting knives for their operations. Besides, the usage of cutting knives has also extended to food processing, pharmaceutical production, and other areas that require precise cutting.The cutting knife is a general term for a diverse range of blades that cut through various materials using a sharpened edge. These blades could be in the form of single-edged blades or double-edged blades, and their composition could range from stainless steel to diamond.However, with the advancements in technology, there has been a tremendous shift from traditional cutting knives to more advanced alternatives like the PU cutting blade.What is a PU cutting blade?PU cutting blade refers to a type of cutting knife made from polyurethane. This material is known for its unique properties, such as high elasticity, durability, and excellent wear resistance. PU cutting blades are used in various industries to cut materials like paper, film, cloth, and leather, among others.One of the primary advantages of using PU cutting blades is their excellent cut quality. The high elasticity of polyurethane allows the blade to flex and adapt to the contours of the material, giving it a clean and precise cut. Moreover, PU cutting blades are non-corrosive, making them ideal for use in humid or wet environments.What are the benefits of using PU cutting blades over traditional cutting knives?1. Increased lifespanPU cutting blades have a more extended lifespan compared to traditional cutting knives. This is because polyurethane has excellent wear resistance, which ensures that the blade retains its sharpness for longer periods.2. High precision cuttingUsing a PU cutting blade ensures high precision cutting due to its excellent cut quality. The blade's flexibility allows it to adapt to the material's contours, ensuring a clean and precise cut.3. Better edge retentionPU cutting blades retain their edges better than traditional cutting knives. This is because the material is not prone to chipping or dulling, ensuring that the blade stays sharp for longer.4. Reduced downtimePU cutting blades do not require regular re-sharpening like traditional cutting knives. This reduces the amount of downtime required for maintenance, ensuring that production runs smoothly.ConclusionIn conclusion, the usage of cutting knives in various industries has revolutionized the manufacturing process. However, with the advancements in technology, there has been a shift from traditional cutting knives to more advanced alternatives like the PU cutting blade. PU cutting blades offer numerous benefits, including increased lifespan, high precision cutting, better edge retention, and reduced downtime. As such, they are becoming increasingly popular in various industries that require precise cutting.

A Guide to the Versatile 3-Hole Knife: Uses and Benefits

Introducing Unique and Innovative 3 Hole Knife by Innovative Kitchen ToolsInnovative Kitchen Tools is proud to announce the launch of their latest product, the 3 Hole Knife. The 3 Hole Knife is a revolutionary kitchen tool that is designed to make slicing and cutting vegetables, fruits, and meats easier and more efficient than ever before.The 3 Hole Knife features a unique design that sets it apart from traditional knives. It is equipped with three precision-cut holes along the blade, which serve multiple purposes. Firstly, these holes reduce friction and allow food to easily slide off the knife, making for a seamless and effortless cutting experience. Additionally, the holes create air pockets, preventing food from sticking to the blade and facilitating a smoother and more even cutting motion.The 3 Hole Knife is crafted from high-quality stainless steel, ensuring durability and longevity. Its ergonomic handle is comfortable to grip, providing users with optimal control and precision. Whether you are a professional chef or a home cook, the 3 Hole Knife is a must-have tool for any kitchen."We are thrilled to introduce the 3 Hole Knife to the market," said a representative from Innovative Kitchen Tools. "We believe that this innovative and versatile knife will revolutionize the way people approach food preparation. Its unique design not only enhances cutting performance but also makes the cooking process more enjoyable and efficient."In addition to its functionality, the 3 Hole Knife is also dishwasher safe, allowing for easy and convenient cleanup. Its sleek and modern design makes it a stylish addition to any kitchen, and its versatility makes it suitable for a wide range of cutting tasks.The 3 Hole Knife has already garnered attention and acclaim from early users and professionals in the culinary industry. Chefs and cooking enthusiasts alike have praised its exceptional performance and the ease with which it handles various ingredients."I have been using the 3 Hole Knife in my kitchen, and I am thoroughly impressed by its performance," said a professional chef. "It has quickly become my go-to knife for all cutting and slicing tasks. Its unique design truly sets it apart from conventional knives, and I can't imagine working without it."The 3 Hole Knife is now available for purchase on the Innovative Kitchen Tools website and select retailers. With its innovative design and superior functionality, the 3 Hole Knife is poised to become an essential tool for anyone who values efficiency and precision in the kitchen.Innovative Kitchen Tools is committed to developing high-quality and innovative kitchen products that enhance the cooking experience for individuals worldwide. With a focus on functionality, durability, and design, the company continues to introduce cutting-edge tools that cater to the needs of modern home cooks and professional chefs alike.

vibrators, Tungsten tip, Tungsten alloy tip, Professional tungsten manufacturer, Tungsten supplier.Tungsten Alloy Vibrator Manufacturer and Supplier: All You Need to KnowTungsten is a rare metal that finds its use in a plethora of industries, including aerospace, defense, electronics, and more. Owing to its exceptional properties, tungsten is widely used in the manufacture of various products, including Tungsten Alloy Vibrators. If you're looking for a professional Tungsten manufacturer or Tungsten supplier for your Vibrator needs, look no further than Chinatungsten.As a professional Tungsten Alloy Vibrator manufacturer and supplier, Chinatungsten offers a broad range of Tungsten-related products, including Tungsten tip and Tungsten alloy tip, to meet the ever-growing demands of its customers worldwide.What is Tungsten Alloy?Tungsten alloy is a blend of tungsten, nickel, and iron or cobalt, with tungsten content varying between 80-98%. The alloy is resistant to heat, corrosion, and wear, making it ideal for high-stress applications. In particular, tungsten alloy is widely used in the defense industry, where high-density materials are essential for radiological shielding, and projectiles.Tungsten alloy has several other applications, including machining tools, radiation shielding, aerospace applications, and electronics.Tungsten Alloy VibratorsTungsten alloy vibrators produced by Chinatungsten are high-density vibrators that can withstand high temperatures and resist corrosion. Tungsten alloy vibrators find their use in several applications, including mineral separation, electronic machines, medical devices, and more.Benefits of Tungsten Alloy VibratorsTungsten alloy vibrators offer several benefits compared to regular vibrators, including:1. High density: Tungsten alloy vibrators boast a high density that allows them to generate strong vibrations, making them ideal for several applications.2. Corrosion and Wear Resistance: Tungsten alloy vibrators are highly resistant to corrosion and wear, making them cost-effective and long-lasting.3. High Melting Point: Tungsten alloy vibrators have a high melting point, making them suitable for high temperature and pressure applications.Tungsten Tip and Tungsten Alloy TipChinatungsten offers Tungsten tips and Tungsten alloy tips in various shapes and sizes. Tungsten tips find their use in drilling, machining, and mining, owing to their outstanding strength and durability.Tungsten alloy tips are commonly used in cutting and milling operations, owing to their excellent heat resistance, toughness, and wear resistance properties.Professional Tungsten Manufacturer and Tungsten SupplierChinatungsten is a professional Tungsten manufacturer and Tungsten supplier that caters to the needs of various industries worldwide. The company has been in the business for over two decades and has built a solid reputation for providing high-quality Tungsten products at competitive prices.Chinatungsten has a robust supply chain and production process that allows the company to deliver Tungsten products worldwide within the shortest time possible. The company complies with international quality standards and undertakes rigorous quality checks to ensure its products meet the requirements of its customers.In ConclusionIf you're looking for a professional Tungsten Alloy Vibrator manufacturer or Tungsten supplier, Chinatungsten is your one-stop-shop. With over two decades in the business, the company has a wealth of experience in producing high-quality Tungsten products that meet the needs of its customers worldwide.Chinatungsten offers Tungsten tips, Tungsten alloy tips, and Tungsten alloy Vibrators that boast high density, wear resistance, corrosion resistance, and high melting point. Head over to their website to learn more about their product offerings and get in touch with their team for all your Tungsten needs.

Top China Blade Manufacturer: Expert Insights and Industry News

China Blade Company, a leading manufacturer of industrial cutting tools, has recently announced the launch of their latest line of high-performance blades. These new blades are designed to provide exceptional cutting efficiency and durability for various industrial applications.With over 20 years of experience in the cutting tools industry, China Blade Company has established itself as a trusted provider of high-quality blades for a wide range of industries, including manufacturing, construction, and automotive. The company’s commitment to innovation and continuous improvement has allowed them to stay at the forefront of the industry, meeting the evolving needs of their customers.The new line of blades incorporates the latest advancements in materials and manufacturing technologies, resulting in a product that offers superior performance and longevity. The blades are designed to withstand the rigors of heavy-duty cutting tasks, delivering precise and reliable results with every use.One of the key features of the new blades is their advanced blade geometry, which is optimized for efficient cutting and reduced friction. This design allows for smoother cutting action, resulting in less wear and tear on the blades and the equipment, as well as improved cutting speed and accuracy.Furthermore, the blades are manufactured using high-quality materials that have been specially chosen for their durability and resistance to wear. This ensures that the blades maintain their sharpness and cutting performance even after prolonged use, making them a cost-effective solution for businesses looking to improve their cutting processes.China Blade Company’s new line of blades also includes options for a variety of cutting tasks, from general-purpose cutting to specialized applications. This versatility allows businesses to find the right blade for their specific needs, ensuring that they can achieve optimal cutting results across different materials and workpieces.In addition to their exceptional performance, the new blades are also designed with user safety in mind. Each blade undergoes rigorous testing to meet industry standards and ensure that they are safe to use in industrial environments. This commitment to safety reflects China Blade Company’s dedication to providing a reliable and responsible product to their customers.“We are excited to introduce our latest line of blades to the market,” said Mr. Zhang, the CEO of China Blade Company. “These new blades represent the culmination of years of research and development, and we are confident that they will deliver exceptional value to our customers.”Mr. Zhang also emphasized the company’s dedication to customer satisfaction, stating that China Blade Company is committed to providing the highest level of support and service to their customers. This includes expert guidance in selecting the right blades for specific applications, as well as ongoing support to ensure that customers achieve the best possible results with their products.As China Blade Company continues to expand its product offerings and reach new markets, their latest line of blades is poised to make a significant impact on the cutting tools industry. With their focus on innovation, quality, and customer satisfaction, the company is well-positioned to maintain its status as a leading provider of industrial cutting solutions.As businesses seek to improve their cutting processes and achieve greater efficiency, China Blade Company’s new line of high-performance blades offers a compelling solution. With their exceptional performance, durability, and versatility, these blades are set to become a valuable asset for businesses across various industries.

Rotary Cutting Tool for Fiber Cable and Microduct: A Game-Changer in Communication Technology

In today's ever-evolving technology landscape, fiber optics has become an integral part of our daily lives. With the rise of 5G technology, high-speed internet, and faster data transfer rates, fiber optic cables have become the backbone of our digital world. However, the installation and maintenance of fiber optic cables can be a daunting task. It requires a specific set of tools and expertise to ensure smooth and uninterrupted service.One of the essential tools in the fiber optic industry is the fiber cutting blade. Fiber cutting blades are used to cut optic fibers and microducts to the required length and diameter accurately. They are used to cut fiber optic cables during installation and maintenance operations. These tools come in various forms, including handheld knives, rotary cutting tools, and specialty cutters. In this blog, we will be discussing the use of fiber cable and microduct rotary cutting tools.Fiber Cable and Microduct Rotary Cutting ToolWhen it comes to cutting fiber cables and microducts, the rotary cutting tools provide precise and efficient cutting solutions. Rotary cutting tools are an essential part of any fiber optic installer's toolkit. They are designed to provide optimal performance and ease of use when cutting through difficult materials like hardened stainless steel or dense fiber optic cables.The fiber cable and microduct rotary cutting tool come in various shapes and sizes to provide the flexibility required when working with different types of cables and microducts. These rotary cutting tools use a spinning blade to cut through the fiber optic cables or microducts. The spinning blade provides precise and smooth cuts to the cable or microduct, ensuring a clean edge that won't cause any damage to the fiber optic strands.The fiber cable and microduct rotary cutting tools come with various features that make them an ideal choice for fiber optic installers. They have an adjustable blade depth, which allows the installer to cut through different thicknesses of the cable or microduct. They also come with ergonomic handles that provide comfortable grip and reduce hand fatigue during extended usage.Another crucial feature of the fiber cable and microduct rotary cutting tools is the blade's material. The blades are made of high-quality materials that ensure durability and longevity. The blades are designed to withstand heavy usage without getting dull or damaged, ensuring a long lifespan for the tool.The fiber cutting blades used in the rotary cutting tools are designed specifically for cutting through fiber optic cables and microducts. They are designed to cut through the cable or microduct without damaging the fiber strands. The fiber cutting blades come in various shapes and sizes to accommodate different types and thicknesses of cables and microducts. They are made of high-quality materials that ensure sharpness and durability.ConclusionIn conclusion, fiber cable and microduct rotary cutting tools have become an essential tool in the fiber optic industry. They provide a precise and efficient cutting solution when working with fiber optic cables and microducts. The adjustable blade depth, ergonomic handle, and high-quality blades make these rotary cutting tools an ideal choice for fiber optic installers.If you're a fiber optic installer or technician, it's crucial to invest in high-quality fiber cutting blades and rotary cutting tools for seamless installation and maintenance operations. Choosing the right fiber cable and microduct rotary cutting tool for the job is crucial to ensure that the cable or microduct is cut with precision and care. It will not only help you save time but also ensure the fiber strands' safety and longevity.