Essential Tips for Choosing the Best Woodworking Blade

By:Admin

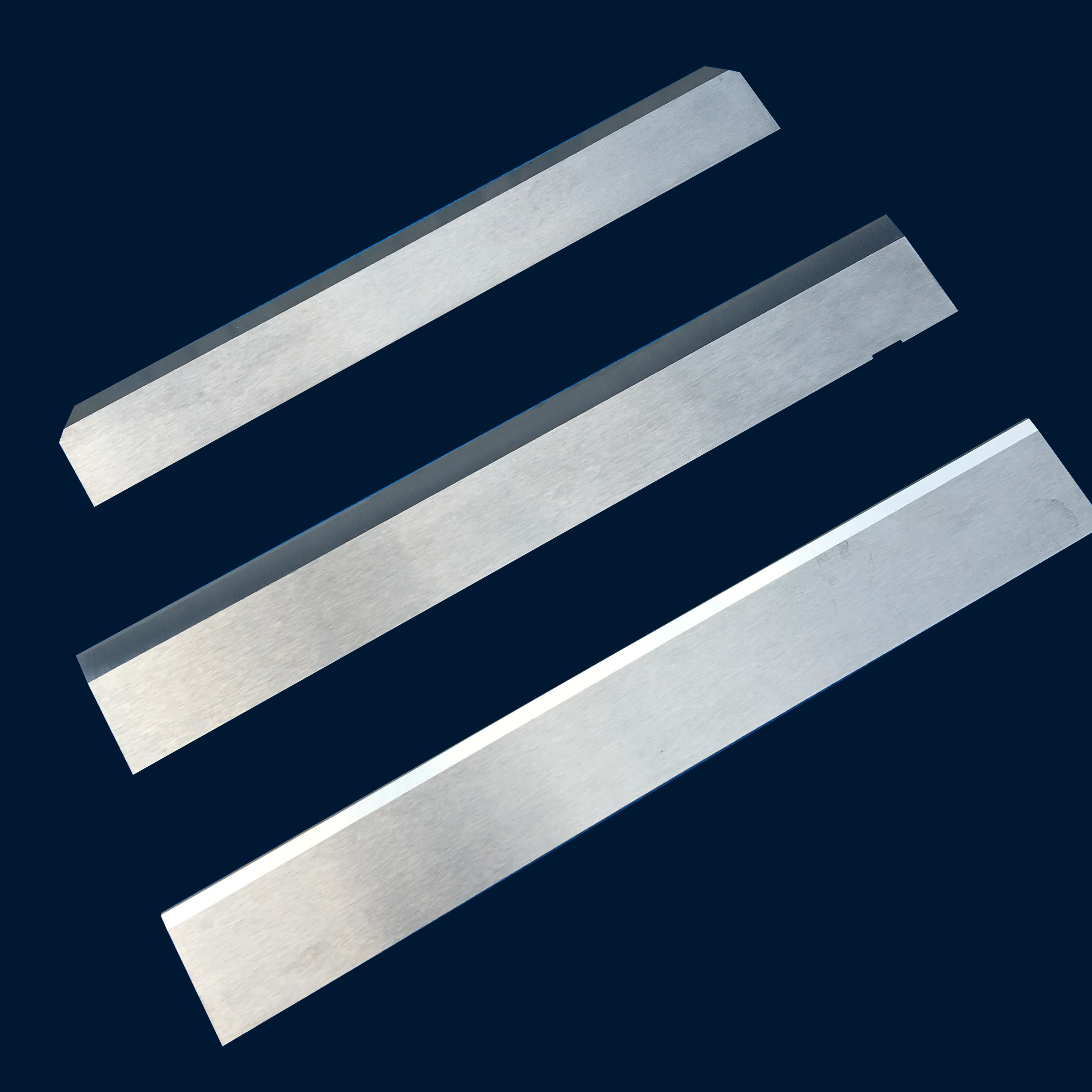

Woodworking Blade (name removed), a leading manufacturer of cutting tools and equipment for the woodworking industry, has announced the launch of their newest product – a revolutionary cutting tool that promises to change the way woodworkers approach their craft.

The new cutting tool, which comes in a variety of blade sizes and configurations, is designed to provide woodworkers with unparalleled precision and control. Its advanced design and engineering allow for clean and accurate cuts, minimizing the need for additional finishing and sanding, and ultimately saving woodworkers time and effort.

"We are thrilled to introduce this cutting-edge tool to the woodworking industry," said the spokesperson for Woodworking Blade (name removed). "Our team of engineers and designers have worked tirelessly to create a product that not only meets, but exceeds, the needs and expectations of woodworkers at all levels. We believe that this new cutting tool will revolutionize the way woodworkers approach their craft, and we can't wait to see the impact it will have on the industry."

In addition to its precision and accuracy, the new cutting tool is also designed to be long-lasting and durable. Made from high-quality materials and manufactured to the highest standards, woodworkers can rely on this tool to deliver consistent and reliable performance, even after repeated use.

Furthermore, the cutting tool has been designed to be compatible with a wide range of woodworking equipment, making it a versatile and valuable addition to any woodworker's toolkit. Whether working with a table saw, miter saw, circular saw, or any other woodworking machinery, woodworkers can trust that this cutting tool will deliver exceptional results.

To further demonstrate their commitment to quality and innovation, Woodworking Blade (name removed) offers a comprehensive warranty on their new cutting tool, providing customers with peace of mind and confidence in their investment.

"Our goal is to not only meet, but exceed the expectations of woodworkers," the spokesperson added. "We understand the demands and challenges of woodworking, and we are dedicated to providing tools and equipment that make the process easier, more efficient, and ultimately more rewarding for woodworkers. We are confident that our new cutting tool will accomplish just that."

The introduction of this new cutting tool solidifies Woodworking Blade (name removed)'s position as a leader in the woodworking industry. With a commitment to innovation, quality, and customer satisfaction, the company continues to set the standard for cutting tools and equipment, inspiring woodworkers to achieve their best work.

Woodworking Blade (name removed) is a company with a rich history in the woodworking industry. With a legacy of craftsmanship and innovation that spans over 50 years, the company has established itself as a trusted and respected name among woodworkers worldwide. Their dedication to excellence and their passion for woodworking has driven them to create cutting-edge tools and equipment that empower woodworkers to achieve outstanding results.

As Woodworking Blade (name removed) continues to push the boundaries of what is possible in woodworking, the introduction of their new cutting tool represents a significant milestone in the company's legacy. With a continued focus on quality, innovation, and customer satisfaction, the company is poised to lead the way in the woodworking industry for years to come. Woodworkers can look forward to more groundbreaking products and solutions from Woodworking Blade (name removed) as the company remains dedicated to shaping the future of woodworking.

Company News & Blog

Revolutionary Carbide Disposable Insert: Discover the Latest Advancements in Cutting Technology

Carbide Disposables – Revolutionizing the Industrial Manufacturing ProcessIn the industrial manufacturing process, the production of high-quality precision components requires the use of cutting-edge technology and the right tools. One critical component in this respect is Carbide Disposables, which have revolutionized the way manufacturers approach their manufacturing processes. Carbide Disposables are a type of cutting tool that is made with carbide, a type of material that is known for its durability and wear resistance.Carbide Disposables are used in various industrial applications, including woodworking, metalworking, and automotive manufacturing. They have become increasingly popular among manufacturers due to their superior cutting performance and extended durability. When compared to traditional steel or high-speed steel cutting tools, Carbide Disposables have a longer lifespan and can cut through materials with a higher degree of precision.As a market leader in the production of Carbide Disposables, our company has a proven track record in manufacturing the highest-quality cutting tools for industrial applications. Our company has been producing cutting tools since the early 1970s and has remained at the forefront of technological advancements in the industry. Our Carbide Disposables product line is a result of years of dedicated research and development, and our cutting-edge manufacturing process ensures that our tools are of the highest quality.Our Carbide Disposables are designed for a range of industrial applications and are available in various shapes and sizes. Our products are designed to meet the needs of customers across different industries, and we offer customized solutions to ensure that our customers get the best tools to fit their specific requirements. Our Carbide Disposables are made using the latest sintering and centerless grinding technologies, which means that they are precision-engineered and have incredibly consistent cutting performance.One of the biggest benefits of using Carbide Disposables is that they require less maintenance when compared to other cutting tools. This is because carbide is incredibly durable and wear-resistant, which means that our Carbide Disposables last longer than conventional cutting tools. This translates into a significant cost-saving for our customers as they do not have to replace cutting tools as frequently.Our Carbide Disposables are not just durable and long-lasting, they also offer superior cutting performance. This is because carbide is a harder material than steel, which means that it can cut through tougher materials with greater ease. Additionally, our Carbide Disposables are made with a precision-ground edge, which ensures that they cut through materials with a higher degree of accuracy. This translates into less waste material and increased efficiency in the manufacturing process.In conclusion, Carbide Disposables have revolutionized the industrial manufacturing process by offering superior cutting performance, enhanced durability, and reduced maintenance requirements. Our company's Carbide Disposables product line is a market leader in the industry, and we pride ourselves in offering customized solutions that meet the needs of our customers. Our Carbide Disposables are a testament to our company's commitment to excellence in manufacturing, and we will continue to develop new and innovative products to meet the evolving needs of the industrial manufacturing sector.

Industrial rotary files: A game-changer for metalworking tasks

Innovation is at the forefront of every industry, and the world of manufacturing is no exception. Wide range of industrial solutions are constantly being unveiled that are designed to make production processes more efficient, time-saving, and cost-effective. One such solution is the Carbide Rotary File. These files are revolutionizing the world of manufacturing and are being widely adopted by companies across the globe. Carbide Rotary Files have become an increasingly popular tool among manufacturers in recent years owing to the many advantages that they offer. They are highly versatile and are used in a variety of applications, ranging from shaping hard metals to creating intricate designs in plastics and wood. They can be used to cut, grind, deburr, shape, and finish a wide range of materials with precision and ease. Carbide Rotary Files are made using high-quality tungsten carbide, which ensures that they are highly durable, long-lasting, and can withstand heavy usage. The Carbide Rotary File is becoming an especially popular tool among manufacturers looking for a faster way to remove material during prototyping and production runs. The tool is capable of carving through metal, composites, wood, and other materials without breaking or dulling quickly, thus saving on downtime. With its speed and efficiency, it can help manufacturers achieve their desired product shape or design in a fraction of the time taken by traditional tools. Its popularity among the manufacturing community has been growing steadily ever since the Carbide Rotary File was introduced. There are several reasons why this tool is becoming increasingly preferred by manufacturers. Firstly, the Carbide Rotary Files are highly versatile. They can be used on a wide range of materials, including steel, aluminum, wood, and plastic, among others. Secondly, they are highly durable and can withstand heavy usage without breaking or dulling. This ensures that manufacturers can use the same file for multiple applications, which saves both time and money. Lastly, the Carbide Rotary Files are easy to use and can be operated by almost anyone without any specialized training or experience. In light of the growing demand for Carbide Rotary Files, several companies have started to manufacture and supply these tools. One such company is a leading supplier of cutting tools based in the United States that offers a wide range of Carbide Rotary Files. The company has over 30 years of experience in the cutting tool industry and has a proven track record of delivering high-quality tools to its clients. The Carbide Rotary Files manufactured by this company are highly rated by users and have received rave reviews. The company uses only the highest quality tungsten carbide to ensure that its files are durable, long-lasting, and can withstand heavy usage. The products are designed to offer maximum flexibility and precision while working with a variety of metals, ceramics, plastics, and composites. The company is also known for its exceptional customer service. It offers timely deliveries and ensures that its customers are satisfied with their orders and the products received. The company also provides routine maintenance for their tools to keep them in good condition and ensure they function optimally. In conclusion, the Carbide Rotary File is an essential tool for modern-day manufacturers looking for a faster and more efficient way of removing material during the prototyping and production processes. These files provide unparalleled flexibility, precision, and durability, making them an ideal solution for cutting, grinding, deburring, shaping, and finishing a wide range of materials. The Carbide Rotary Files offered by the leading supplier of cutting tools in the United States exemplify the latest in innovation and are being widely adopted by manufacturers across the globe.

New Tapered Blade Design Enhances Bag Cutting Efficiency

Bag Taper Blade – Revolutionizing the Packaging IndustryFor businesses that deal with packaging, finding the most efficient and cost-effective solutions is essential. In recent years, Bag Taper Blade has emerged as a game-changer in the industry. This innovative product makes the process of sealing bags faster, easier, and more precise than ever before. With its exceptional performance, it has become a success story. Bag Taper Blade is a product of {company name}, a reputable manufacturer and distributor of packaging tools and accessories. The company has been providing high-quality solutions to customers for many years. They understand the needs of the packaging industry and are continually looking for ways to upgrade and enhance their product line.The Bag Taper Blade is one such product that the company has developed with a clear understanding of the packaging industry's requirements. This tool is designed to be durable, efficient, and easy to use. It is made of high-quality steel that can withstand heavy usage and endure harsh environments. The blade is also resistant to corrosion, which ensures its longevity and reliability.One of the most notable benefits of Bag Taper Blade is its speed. It can seal bags quickly and effortlessly, averting delays and increasing productivity. This is particularly beneficial for businesses that require high output while maintaining quality standards. The product has been tested and proven to work faster than traditional sealing machines, making it an excellent investment for businesses that prioritize efficiency.Another essential feature of Bag Taper Blade is its precision. The blade is designed to seal bags evenly, preventing any leaks or spillage. This means that businesses can package their products efficiently, ensuring that they maintain quality and integrity during transportation and storage. The precision of the blade also minimizes the risk of waste, which can save money for businesses in the long run.The Bag Taper Blade is also easy to use. It requires minimal training as it is straightforward and user-friendly. The blade is designed to fit onto most sealing machines, making it convenient for businesses that do not want to replace their equipment. The blade's installation process is simple and straightforward, and it can be done without the need for any additional tools.Perhaps one of the most significant advantages of Bag Taper Blade is its versatility. It can be used in a wide range of industries, including food and beverage, agriculture, pharmaceuticals, and more. The product's flexibility provides businesses with a lot of options and the ability to adapt to different packaging needs.In conclusion, the Bag Taper Blade has revolutionized the packaging industry, providing businesses with a cost-effective, efficient, and reliable sealing solution. Its numerous benefits, including speed, precision, ease of use, and versatility, make it a must-have for businesses looking to stay ahead of the curve. With its exceptional performance, Bag Taper Blade has become an industry leader, providing innovative solutions that meet the changing needs of businesses. The Bag Taper Blade is available for purchase online on {company name}'s website. Their support team is always ready to assist in choosing and installing the blade to ensure that businesses experience maximum efficiency and return on investment.

Essential Tools: Unveiling the Power of Straight Paint Scraper Blades

Title: Straight Paint Scraper Blades: The Perfect Solution for Your Painting NeedsIntroduction:Painting can be a therapeutic and satisfying experience, but removing old paint or working on intricate areas can be a daunting task. That is where the Straight Paint Scraper Blades come in. Offering precision, durability, and ease of use, these paint scraper blades are revolutionizing the painting industry. In this article, we will delve into the features and benefits of these remarkable tools, ensuring that your next painting project is a breeze.Company Introduction: XXXX Company is a leading manufacturer of innovative painting tools and accessories. With years of experience in the industry, their products stand out for their exceptional quality, reliability, and functionality. Aimed at simplifying the painting process and improving efficiency, XXXX Company continuously endeavors to offer top-notch tools to professionals and DIY enthusiasts alike.Features of Straight Paint Scraper Blades:1. Unparalleled Durability: Straight Paint Scraper Blades are made from high-quality materials, ensuring exceptional longevity and resistance to wear and tear. These blades are built to last and can withstand the toughest of painting tasks.2. Precision and Versatility: The sharp, straight edge of these paint scraper blades enables precise and accurate paint removal, even in intricate areas. Whether you need to remove paint from window frames, cabinets, or any other surface, Straight Paint Scraper Blades provide the perfect solution.3. Ergonomic Design: Comfort matters, especially during long painting projects. Straight Paint Scraper Blades are designed with ergonomics in mind. The handles are optimized for a comfortable grip, reducing hand fatigue and making paint removal a hassle-free experience.4. Safe and Efficient: XXXX Company prioritizes safety in their products. Straight Paint Scraper Blades feature safety caps that cover the sharp edge when not in use. This ensures protection against accidental cuts, making them safe to handle even when not wearing protective gloves.5. Multiple Blade Sizes: Recognizing that every painting project has different requirements, Straight Paint Scraper Blades are available in various sizes. This enables users to choose the most suitable blade based on the specific task at hand, ensuring optimal performance.Benefits of Using Straight Paint Scraper Blades:1. Time-Saving: The sharp edge of the paint scraper blades makes the process of paint removal quick and efficient. Spending less time on this task allows for more time to focus on other aspects of your painting project.2. Cost-Effective: With their exceptional durability, Straight Paint Scraper Blades offer a cost-effective solution for paint removal. You won't have to spend money on frequent replacements, saving you both time and money in the long run.3. Enhanced Paint Preparation: Preparing a surface for painting is crucial for achieving a high-quality finish. The use of Straight Paint Scraper Blades ensures a smooth and clean surface, enabling better adhesion and longevity of the new paint.4. Versatile Application: Whether you are a professional painter or a homeowner working on a DIY project, Straight Paint Scraper Blades are suitable for all skill levels. Their versatility allows you to tackle various painting tasks with ease, providing professional results every time.Conclusion:In the realm of painting, having the right tools can make a world of difference. Straight Paint Scraper Blades, offered by XXXX Company, provide a convenient and effective solution for any paint removal job. Empowering users with durability, precision, and versatility, these scraper blades are the choice of professionals worldwide. So, next time you have a painting project, equip yourself with Straight Paint Scraper Blades and witness the transformation of your paint removal process.

Top-Quality Double Edge Safety Razor Blades with Teflon and Chrome Platinum Coating

Bic Maggard Razors, a leading company in the shaving and grooming industry, has launched their latest product in the market - a line of double edge safety razor blades. Made with top-quality stainless steel, these blades are triple honed and coated with Teflon and chrome platinum. The product is made in Greece and promises to be a game-changer in the industry.The company takes pride in delivering superior quality products to its consumers. They ensure that their products are durable, well-designed and deliver excellent performance. With their newest addition, the company is keeping up with its reputation and is expected to set new standards in the market.The double edge safety razor blades are suitable for all skin types and are designed to provide a seamless shaving experience. The sharpness of the blades is well-balanced with the triple honing, providing a smooth cut with little to no irritation. The Teflon and chrome platinum coating makes the blades rust-resistant and adds to their longevity.It has been reported that the double edge safety razor blades by Bic Maggard Razors have been tested by a panel of experts, and the results have been favorable. The testers were impressed with the quality of the blades and how they performed. The blades have also been reviewed by regular users, who have reported the same outcome. The reviews pointed towards the longevity of the product and how well they shaved. Moreover, they mentioned the added benefit of cost-effectiveness, as the blades are said to last longer than other razors in the market.The company spokesperson was thrilled with the response from the audience. He stated, “We are excited about the launch of our double edge safety razor blades. We take pride in our products, and these blades are no exception. Our priority is to deliver superior quality products that are both cost-effective and efficient. And with these double edge safety razor blades, we are doing just that.”Bic Maggard Razors has been a trusted name in the shaving and grooming industry for many years. The company has come a long way, expanding its product line and innovating to bring the latest and the best in the market. The company is dedicated to delivering quality products that provide value to its customers.In recent years, there has been a shift towards using traditional shaving methods, and Bic Maggard Razors has been at the forefront of this trend. The company has been catering to the market demand by providing consumers with high-quality products that help them achieve the perfect shave.The double edge safety razor blades by Bic Maggard Razors are expected to take the industry by storm. The product is an excellent choice for individuals who prefer a classic shaving experience. Moreover, the blades are easy to replace, so consumers can switch them out as often as necessary, adding to their convenience.In conclusion, Bic Maggard Razors has done it again with their newest addition to the product line. The double edge safety razor blades are an excellent choice for anyone looking for a cost-effective way to achieve a smooth and comfortable shave. With their top-quality stainless steel, triple honing, and Teflon and chrome platinum coating, these blades are sure to impress. The company continues to set new industry standards with its innovative products, making them a go-to choice for anyone looking for quality in shaving and grooming products.

The Ultimate Guide to Paint Scraper Blades: Everything You Need to Know

Paint Scraper Blades are an essential tool for any painter or decorator. Whether you’re a professional tradesperson or a DIY enthusiast, having the right equipment can make all the difference when it comes to achieving a high-quality finish.One brand that has been making waves in the industry is {brand name}. Their range of high-quality paint scraper blades are designed to make the paint removal process quicker and easier, saving you time and effort on your projects.{Brand name} is a leading manufacturer of professional-grade paint scraper blades. Their products are trusted by professionals and DIYers alike for their durability, precision, and performance. With a commitment to quality and innovation, {Brand name} has become a go-to choice for those seeking reliable and effective paint scraper blades.The company’s dedication to quality is evident in their materials and manufacturing processes. Their blades are made from high-quality steel, ensuring they can withstand the rigors of everyday use. This durability means that {Brand name}’s paint scraper blades are long-lasting, providing excellent value for money.In addition to their durability, {Brand name}’s paint scraper blades are also designed for precision. The company’s innovative manufacturing techniques result in blades that are sharp and precise, allowing for smooth and efficient paint removal. This precision is crucial for achieving a professional finish, whether you’re working on a small DIY project or a large-scale commercial job.{Brand name} offers a wide range of paint scraper blades to suit different needs and preferences. From standard straight blades to angled and hooked blades, they have a variety of options to cater to various scraping requirements. This extensive range ensures that customers can find the perfect blade for their specific project, no matter the size or complexity.With a commitment to customer satisfaction, {Brand name} also provides excellent customer service and support. Their team of experts is on hand to offer advice and assistance, ensuring that customers can get the most out of their products. This dedication to customer care has helped {Brand name} build a loyal and satisfied customer base over the years.In addition to their quality products and customer service, {Brand name} is also dedicated to sustainability and environmental responsibility. The company strives to minimize its environmental impact by using eco-friendly materials and processes wherever possible. This commitment to sustainability ensures that customers can feel good about choosing {Brand name} for their paint scraper blade needs.With all these factors combined, it’s no wonder that {Brand name} has become a trusted name in the industry. Their dedication to quality, innovation, and customer satisfaction sets them apart from their competitors, making them a top choice for those in need of reliable paint scraper blades.In conclusion, {Brand name} is a leading manufacturer of professional-grade paint scraper blades that are trusted by professionals and DIYers alike. With a commitment to quality, precision, and customer satisfaction, {Brand name} has established itself as a go-to choice for those seeking high-quality paint scraper blades. Whether you’re working on a small DIY project or a large-scale commercial job, {Brand name} has the perfect blade to meet your needs. With their dedication to sustainability and environmental responsibility, customers can feel good about choosing {Brand name} for their paint scraper blade needs.

Circular Blades for Cigarette Filter Rod Cutting: Tungsten Carbide Circular Cutting Knives in 88x16x0.25mm Size

Eight Cutters Inc. is proud to announce its latest addition to its extensive range of cutting tools – the 88x16x0.25mm circular blades, made from Tungsten Carbide. With the increased demand for cigarette filtering machinery in recent years, these blades are the most suitable tools to process cigarette filters.At Eight Cutters Inc., we are committed to delivering premium quality cutting tools for various industries. Our Tungsten Carbide circular blades are the result of years of research, development, and experience in the cutting tool industry. We have invested in advanced technology and equipment to ensure that our clients receive top-quality products that meet their industry’s specific requirements.The regular size of the slitting knives is OD88xID16xTHK0.26mm. However, we can customize them based on your specific needs. Our tungsten carbide blades are renowned for their incredible durability, resistance to wear, and high-quality finishes. These blades are designed to provide precision cuts, reduce the need for frequent blade changes, and optimize your cutting process’s productivity.Tungsten carbide is the primary material used in these blades as it is a high-performance material that offers superior durability and wear resistance. Its unique properties make it ideal for use in the high-speed cutting of cigarettes. The blades are also manufactured to the highest standards, making them easy to adjust and maintain, ensuring precision in every cut.Our 88x16x0.25mm circular blades are the perfect fit for cigarette filter rod cutting, as they offer clean and precise cuts for high-speed cigarette manufacturing machinery. Our blades are also versatile enough to be employed in different cutting processes, making them an essential tool for a wide range of industries.We are proud to hold a reputation for quality, reliability, and efficiency, and at Eight Cutters Inc., we continuously strive to exceed our customers’ expectations. Our cutting tools are always available and ready for shipping to our customers worldwide. When you choose us, rest assured that our customer support team is available to provide prompt support and solutions to any queries or issues you may have.Our products are accessible to clients all over the globe, and we offer flexible shipping and payment options to make sure that our customers receive the products at their convenience. You can order our Tungsten Carbide blades directly from our website or through our sales team. Our team is always available to discuss your needs and suggest the best tooling solutions for your applications.In conclusion, the 88x16x0.25mm circular blades manufactured from Tungsten Carbide are the most suitable tool for processing cigarettes and other filter rods. Eight Cutters Inc. is proud to be at the forefront of the cutting tool industry, delivering top-quality cutting tools to different industries worldwide. We value our customers’ satisfaction and continuously work towards improving our products and services to meet their evolving needs. Choose us today and experience the difference in our top-quality cutting tools.

Discover the Latest Insights on Tobacco Filter Rods Slitter Knives

Tobacco Filter Rods Slitter Knives: Revolutionizing Efficiency in Tobacco ProductionTobacco production has always been an industry that demands precision and efficiency. With the increasing demand for cigarettes across the globe, manufacturers constantly search for innovative solutions to improve their production processes. Recently, a pioneering company has launched a groundbreaking tool that is set to revolutionize the tobacco industry – the Tobacco Filter Rods Slitter Knives.Introducing a Perfect Harmony of Quality and EfficiencyThe Tobacco Filter Rods Slitter Knives, developed by a leading manufacturer in the field, are designed to offer a perfect harmony of quality and efficiency in the tobacco production process. With their state-of-the-art technology and meticulous craftsmanship, these knives are poised to transform the way filter rods are slit, resulting in significant improvements in production speed and accuracy.The company behind this groundbreaking invention has been a trailblazer in the tobacco machinery industry for over two decades. They have consistently delivered cutting-edge solutions that have helped tobacco companies streamline their production processes and enhance their product quality. Their deep understanding of the tobacco industry's requirements has enabled them to create tools that not only meet industry standards but also exceed expectations.Enhancing Efficiency and PrecisionThe Tobacco Filter Rods Slitter Knives are specifically designed to enhance the efficiency and precision of the tobacco production process. These knives are crafted with the highest quality materials, ensuring durability and longevity, even under demanding operating conditions. The company utilizes advanced manufacturing techniques and stringent quality control measures to guarantee exceptional performance.One of the key features of these knives is their ability to achieve precise slitting of filter rods. The intricate design and sharpness of the blades enable manufacturers to achieve consistent and accurate cuts, ensuring that each filter rod meets the desired specifications. This feature not only reduces waste in the production line but also ensures that the final product is of the highest quality.Furthermore, the Tobacco Filter Rods Slitter Knives are designed for easy installation and maintenance. The company provides comprehensive user manuals and technical support to assist customers in incorporating these knives seamlessly into their production systems. This user-friendly approach ensures that tobacco manufacturers can swiftly integrate this innovative tool into their existing processes, without causing disruptions or delays.Advancing the Tobacco IndustryThe introduction of the Tobacco Filter Rods Slitter Knives marks a significant milestone in the tobacco industry. This groundbreaking tool is set to revolutionize the way filter rods are slit, ultimately improving productivity, reducing waste, and enhancing the overall efficiency of tobacco production. By embracing this cutting-edge technology, manufacturers can stay ahead of the competition and meet the ever-growing demands of the tobacco market.With its commitment to innovation and continuous improvement, the company behind the Tobacco Filter Rods Slitter Knives ensures that its customers benefit from the latest advancements in the industry. They continue to invest in research and development, striving to create new solutions that address the evolving needs and challenges of tobacco manufacturers worldwide.ConclusionThe Tobacco Filter Rods Slitter Knives represent a game-changer for the tobacco industry, promising to streamline production processes and elevate product quality to new heights. As this revolutionary tool makes its mark in the market, tobacco manufacturers can look forward to improved efficiency, increased profitability, and enhanced customer satisfaction. With its combination of precision, durability, and ease of use, these knives undoubtedly have the potential to reshape the future of the tobacco production industry.

High-Quality Pelletizer Shredder Blades for Rotary Plastic Auxiliary Machine

Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades: A New Era for Plastic RecyclingThe world is facing a major environmental crisis due to the overconsumption of plastic and the lack of proper disposal and recycling methods. According to a study published by the World Economic Forum, by 2050, the ocean’s plastic will outweigh fishes, which will make up to approximately 12 billion tonnes. This alarm, along with a rising awareness of the need for sustainability, has urged individuals, communities, and companies to work towards cleaner and greener futures. Among these, manufacturers of machinery and tools have innovated and collaborated with researchers and organic entities to develop solutions for the proper management and recycling of plastic materials, which is an underlying cause of plastic waste buildup.One notable example of this is the Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades, a product manufactured in China and distributed worldwide. The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades serve as plastic auxiliary equipment used for melting, mixing, and shaping different types of plastics. It is used in the production of granules, fibers, and filaments for various industrial applications, particularly in the recycling of plastic waste.These machines are designed to offer accuracy, precision, and efficiency in plastics processing. They have a large tolerance range, which makes them ideal for processing different types of plastics, including hard-to-process plastics, such as those with high melting points, low densities, or high viscosities. The blades are made of high-strength steel and undergo comprehensive heat treatment processes that allow them to withstand impact, wear, and deformation.The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades' operational principles follow the shredding and granulation processes. The shredding process involves the reduction of plastic waste materials into smaller pieces through the use of shredding blades rotating at high speeds. The granulation process, on the other hand, involves heating and melting the plastic waste pieces before pushing them through the orifice of the die to form the desired granules or pellets shape. Continual production of granules, fibers, or filaments then occurs, depending on the customer's needs.The applications of these machines are diverse, and they can be applied to the agricultural, automotive, construction, electrical, packaging, and textile industries. They have found their place in the efforts to address the plastic waste problem, particularly in "grassroots recycling" projects led by communities and individuals. Also, their affordability has made them an important tool for recycling in resource-limited communities.Manufacturing companies worldwide have taken note of the advantages of this innovation. The rotary plastic auxiliary machines and pelletizers come with a low running cost, have high efficiency, and are environmentally friendly. Thus, many companies are integrating them into their recycling plants for sustainable plastic production. The product has gained recognition and acceptance in the market, driven by high demand for durable, versatile tools that can process different types of plastics.Overall, the Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades represent a critical tool that can significantly reduce the environmental footprint of plastic processing. The innovation represents a crucial step towards more sustainable and responsible solutions within the industry. The low cost, efficiency, and versatility make these machines ideal for both developing and developed countries, where proper plastic recycling, recovery, and upcycling are vital. Furthermore, it highlights the impact that innovation and collaboration can have on addressing pressing environmental challenges, and the need to support and encourage such solutions. In conclusion, combating plastic waste and promoting a circular economy requires a combination of innovative technologies and public and private partnerships. The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades represent one of many innovations aimed at solving the complex problem of plastic waste and are proof that sustainable production methods can be effective and commercially viable.