Discover the Best Paint Scraper Blades for Effective Surface Removal

By:Admin

Introduction:

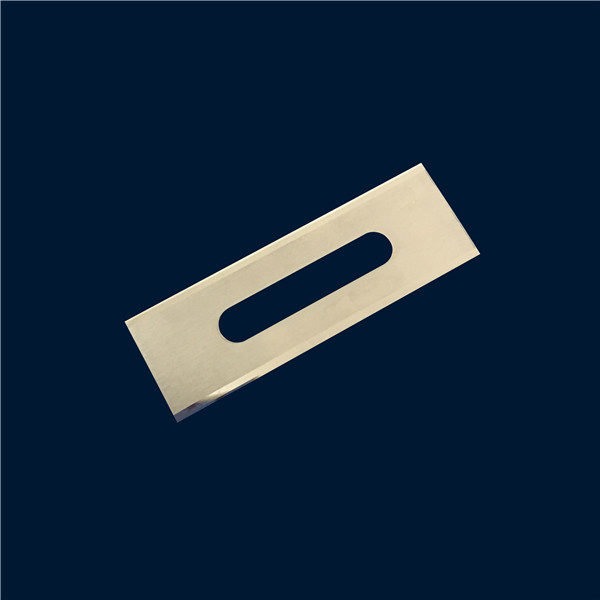

In the realm of surface preparation, Paint Scraper Blades have continually proven their efficacy in achieving smooth and polished finishes. Known for their exceptional quality and durability, these versatile tools are widely used by professionals and DIY enthusiasts alike. Manufactured with precision and engineered to handle various materials, Paint Scraper Blades ensure a seamless and hassle-free paint removal process, making them an indispensable tool in any toolkit.

[Company Name], a renowned manufacturer of high-quality paint scraper blades, has witnessed tremendous success in the industry due to their commitment to excellence and customer satisfaction. With a diverse range of innovative products, the company has positioned itself as a market leader, catering to the needs of professionals in the painting and decorating industry.

Body:

1. Introduction to Paint Scraper Blades:

- Paint scraper blades are essential tools for any surface preparation job, aiding in the efficient removal of paint, varnish, and other coatings.

- Traditionally made from high-grade steel, these blades are engineered to resist wear and tear, ensuring a long lifespan and optimal performance.

2. [Company Name]: Revolutionizing Surface Preparation:

- [Company Name] is a leading manufacturer of paint scraper blades, trusted by professionals worldwide for their exceptional quality and craftsmanship.

- The company's commitment to innovation, coupled with extensive research and development, has allowed them to create cutting-edge scraper blade designs.

- [Company Name]'s state-of-the-art manufacturing facilities adhere to strict quality control processes, guaranteeing consistent and reliable products.

3. Specialized Blades for Different Surface Preparation Needs:

- [Company Name] offers a comprehensive range of paint scraper blades tailored to meet specific surface preparation requirements.

- The company's lineup includes multi-edge blades, carbide-tipped blades, and extended reach blades, ensuring versatility and efficiency in various projects.

- Their carbide-tipped blades provide exceptional durability and are specially designed to handle tough surfaces such as concrete, brick, and metal.

4. Professional-Grade Durability and Performance:

- Paint Scraper Blades by [Company Name] are known for their exceptional durability, enabling professionals to undertake demanding tasks without frequent replacements.

- The blades' precise cutting edge allows for effortless paint removal, reducing the need for excessive force and minimizing the risk of damage to the underlying surface.

- Designed with ergonomics in mind, [Company Name]'s blades offer a comfortable grip, reducing hand fatigue during extended periods of use.

5. Customer Satisfaction and Industry Recognition:

- [Company Name] takes pride in its commitment to customer satisfaction and has built a strong reputation for providing top-notch products and services.

- With a focus on continuous improvement, the company actively seeks customer feedback to enhance product performance and design.

- Their dedication to quality has earned them accolades within the industry, with numerous professionals relying on their blades for superior surface preparation results.

Conclusion:

Paint Scraper Blades by [Company Name] have become synonymous with quality and efficiency in surface preparation. With their commitment to innovation and customer satisfaction, the company has solidified its position as a market leader in manufacturing top-grade scraper blades. Whether it is paint removal, varnish stripping, or general surface preparation, professionals and DIY enthusiasts can rely on [Company Name]'s versatile and durable products to achieve outstanding finishes.

Company News & Blog

Industrial rotary files: A game-changer for metalworking tasks

Innovation is at the forefront of every industry, and the world of manufacturing is no exception. Wide range of industrial solutions are constantly being unveiled that are designed to make production processes more efficient, time-saving, and cost-effective. One such solution is the Carbide Rotary File. These files are revolutionizing the world of manufacturing and are being widely adopted by companies across the globe. Carbide Rotary Files have become an increasingly popular tool among manufacturers in recent years owing to the many advantages that they offer. They are highly versatile and are used in a variety of applications, ranging from shaping hard metals to creating intricate designs in plastics and wood. They can be used to cut, grind, deburr, shape, and finish a wide range of materials with precision and ease. Carbide Rotary Files are made using high-quality tungsten carbide, which ensures that they are highly durable, long-lasting, and can withstand heavy usage. The Carbide Rotary File is becoming an especially popular tool among manufacturers looking for a faster way to remove material during prototyping and production runs. The tool is capable of carving through metal, composites, wood, and other materials without breaking or dulling quickly, thus saving on downtime. With its speed and efficiency, it can help manufacturers achieve their desired product shape or design in a fraction of the time taken by traditional tools. Its popularity among the manufacturing community has been growing steadily ever since the Carbide Rotary File was introduced. There are several reasons why this tool is becoming increasingly preferred by manufacturers. Firstly, the Carbide Rotary Files are highly versatile. They can be used on a wide range of materials, including steel, aluminum, wood, and plastic, among others. Secondly, they are highly durable and can withstand heavy usage without breaking or dulling. This ensures that manufacturers can use the same file for multiple applications, which saves both time and money. Lastly, the Carbide Rotary Files are easy to use and can be operated by almost anyone without any specialized training or experience. In light of the growing demand for Carbide Rotary Files, several companies have started to manufacture and supply these tools. One such company is a leading supplier of cutting tools based in the United States that offers a wide range of Carbide Rotary Files. The company has over 30 years of experience in the cutting tool industry and has a proven track record of delivering high-quality tools to its clients. The Carbide Rotary Files manufactured by this company are highly rated by users and have received rave reviews. The company uses only the highest quality tungsten carbide to ensure that its files are durable, long-lasting, and can withstand heavy usage. The products are designed to offer maximum flexibility and precision while working with a variety of metals, ceramics, plastics, and composites. The company is also known for its exceptional customer service. It offers timely deliveries and ensures that its customers are satisfied with their orders and the products received. The company also provides routine maintenance for their tools to keep them in good condition and ensure they function optimally. In conclusion, the Carbide Rotary File is an essential tool for modern-day manufacturers looking for a faster and more efficient way of removing material during the prototyping and production processes. These files provide unparalleled flexibility, precision, and durability, making them an ideal solution for cutting, grinding, deburring, shaping, and finishing a wide range of materials. The Carbide Rotary Files offered by the leading supplier of cutting tools in the United States exemplify the latest in innovation and are being widely adopted by manufacturers across the globe.

How to Cut Holes in Cement Backer Board with a Jigsaw: A Homeowner's Guide to Cutting Hardie Backer Board. Blade Options for Cutting Cement Backer Board.

for Effective Backer Board Installation. When it comes to installing tile or other types of flooring in your home, proper preparation is essential for a successful outcome. One of the most important steps is installing the right backer board. Hardie board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. However, cutting Hardie backer board can be a challenge without the right tools and techniques. In this post, we will discuss how to cut holes in cement backer board with a jigsaw and the importance of choosing the right Hardie plank cutting blade.Cutting Holes in Cement Backer Board with a JigsawMany DIY enthusiasts and professional contractors alike prefer using a jigsaw for cutting holes in cement backer board. With its fine-toothed blade, a jigsaw can make precise cuts quickly and easily. To get started, you will need the following tools:- A jigsaw with a fine-toothed blade - A straight edge - Safety glasses - Dust mask - Gloves Here are the steps to follow:1. Place the cement backer board on a work surface, such as a sawhorse or workbench.2. Use a straight edge to mark the shape of the hole you want to cut 3. Put on your safety glasses, dust mask, and gloves 4. Insert the jigsaw blade into the hole you have drilled in the cement backer board 5. Turn on the jigsaw and follow the outline you have marked on the backer board 6. Apply firm and steady pressure as you cut through the cement backer board Choosing the Right Hardie Plank Cutting BladeTo achieve a clean cut on your cement backer board, you must use the right type of blade. A Hardie plank cutting blade is specially designed to cut through fiber cement products like Hardie board. Here are some factors to consider when choosing the right blade:- Tooth configuration: The blade should have a double-row configuration with extra-sharp teeth to prevent chipping and splintering - Diameter: The diameter of the blade must be suitable for the type of tool you are using - Material: Choose a blade made of high-quality carbide-tipped material, which is durable and long-lasting In summary, Hardie backer board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. Cutting holes in cement backer board with a jigsaw is a great option for those who prefer a fine-toothed blade. To achieve a clean cut, it is essential to choose the right Hardie plank cutting blade. With these tips in mind, you can install your Hardie backer board with ease and confidence.

Boost Your Cutting Precision with High-Quality Plotter Blades

[Introduction]In the ever-evolving world of industrial cutting tools, Plotter Blades (brand name omitted) have emerged as a prominent player, offering high-quality and efficient solutions for various applications. With a commitment to innovation, durability, and precision, Plotter Blades has become a go-to choice for professionals seeking excellence in their cutting tasks. With a comprehensive range of products, this company has garnered a solid reputation in the market, delivering exceptional performance and reliability to customers worldwide.[Company Overview]Plotter Blades, founded by a team of industry experts, has swiftly established itself as a leading manufacturer of cutting-edge blades, designed to meet the diverse needs of its customers. The company's primary focus lies in producing blades that are both durable and precise, ensuring smooth and accurate cutting performance across a wide range of materials. With an unwavering commitment to quality, Plotter Blades continues to push the boundaries of blade technology, constantly striving to exceed customer expectations.[Product Range]The product portfolio of Plotter Blades encompasses an extensive range of blades, catering to various industries such as automotive, packaging, textile, signage, and advertising. Each blade is meticulously designed and crafted to fulfill specific cutting requirements, ensuring optimal results for professionals in their respective fields.The company offers blades suitable for different cutting machines, including vinyl cutters, digital plotters, CNC routers, and oscillating knife cutters. These blades are available in a variety of materials such as tungsten carbide, high-speed steel, and ceramic, allowing customers to choose the most appropriate option for their specific applications.[Innovation and Technology]Plotter Blades prides itself on its continuous efforts to develop and incorporate cutting-edge technology into its products. By staying at the forefront of technological advancements, the company ensures its customers benefit from the latest innovations in the industry.Utilizing advanced manufacturing techniques, Plotter Blades ensures consistent quality and superior performance in every blade. The company's research and development team constantly works to refine blade designs, resulting in improved cutting efficiency and extended blade life. This commitment to innovation has positioned Plotter Blades as a trusted brand among professionals seeking the best possible cutting solutions.[Quality Control]Maintaining stringent quality control measures is a top priority for Plotter Blades. From selecting high-grade raw materials to rigorous testing at every stage of production, the company leaves no stone unturned in ensuring its blades meet the highest standards. Stringent quality control protocols are in place, including comprehensive inspection and analysis, to guarantee that each blade leaving the factory is flawless in terms of durability, sharpness, and accuracy.[Catering to Customer Needs]Plotter Blades understands that the success of its customers relies on their ability to deliver superior results. As a result, the company places great emphasis on understanding the specific needs of its customers and tailoring its products accordingly. With a team of technical experts, Plotter Blades offers personalized guidance and support to help customers select the most suitable blades for their applications, ensuring they achieve optimal cutting performance.[Market Presence]With a strong presence in both domestic and international markets, Plotter Blades is dedicated to providing its exceptional products and services to customers around the globe. The company's commitment to customer satisfaction and its ability to consistently deliver high-quality blades have earned it a loyal customer base and established its reputation as a reliable market player.[Conclusion]Plotter Blades stands as a beacon of innovation and excellence in the field of industrial cutting tools. Its unwavering commitment to quality, cutting-edge technology, and customer satisfaction places it at the forefront of the industry. As Plotter Blades continues to expand its product range and reach new heights of success, professionals can rely on its blades to meet their cutting needs with precision and efficiency.

Hard and High-Quality Circular Cutting Knives and Blades for Various Applications

Circular knives are essential tools for many industries. They are used for a variety of cutting tasks such as cutting cartons, leather, textiles, food products and even metals. It is crucial to choose the right kind of knife for each specific task to ensure optimal performance. In this blog, we will discuss circular knives that are commonly used for cutting cartons, and specifically, the round wood saw Fujian blade, steel cutting machine for circular blade Fujian cutter, and slotting carton on scimitar.A carton cutting circular knife is a blade that is specifically designed to cut through cardboard and other similar materials. These knives are used in various industries, such as packaging, printing, and cardboard box manufacturing. These industries require a specific type of circular knife that can cut through cartons quickly and efficiently. There are different types of carton cutting circular knives, and three of the most common are the round wood saw Fujian blade, steel cutting machine for circular blade Fujian cutter, and slotting carton on scimitar.The round wood saw Fujian blade is a circular knife that is specifically designed for cutting through wood. It is made with a high-quality steel material that is durable and long-lasting. The blade has sharp teeth that can easily cut through wood without getting stuck or frayed. This blade is perfect for cutting pallets, crates, and other wooden items that are used in the packaging industry.The steel cutting machine for circular blade Fujian cutter is another type of carton cutting circular knife. This blade is designed for cutting through steel and other metals. It is made with high-quality steel that is strong and long-lasting. The blade has sharp teeth that can cut through steel quickly and efficiently without getting stuck or overheating. This blade is perfect for cutting metal sheets, pipes, and other metal items that are used in the manufacturing industry.The slotting carton on scimitar is another type of carton cutting circular knife that is commonly used in the packaging industry. This blade has a unique design that enables it to cut slits in cartons. The blade has a curved edge that is ideal for making precise cuts in cartons without damaging the contents inside. This blade is perfect for cutting slits in cartons that are used for packaging food, medicine, and other delicate items.In conclusion, choosing the right circular knife is essential for ensuring optimal performance and productivity. The round wood saw Fujian blade, steel cutting machine for circular blade Fujian cutter, and slotting carton on scimitar are three types of carton cutting circular knives commonly used in the packaging, printing, and manufacturing industries. These blades are all designed to cut through specific types of materials efficiently and effectively. So, if you need to cut cartons or other materials for your business, make sure to choose the right circular knife for your specific task. Keywords: Carton Cutting Circular Knives.

Latest Updates on Knife and Slitting Knife Manufacturing in China

China Knife and Slitting Knife Industry Set to Flourish as Global Demand RisesIn a world that constantly strives for innovation and advancement, industries play a pivotal role in shaping the economy. Among the many flourishing sectors in China, the knife and slitting knife industry stand out as a pioneering force, contributing significantly to the country's economic growth. With a rich history and a commitment to quality, Chinese manufacturers are poised to capitalize on the growing global demand for knives, slitting knives, and related tools.China has a long-standing tradition of craftsmanship when it comes to knives, dating back several centuries. Over the years, the industry has developed and evolved to meet the changing needs of consumers and businesses alike. Today, China is known as one of the world's largest exporters of cutting tools, producing a vast range of knives, including kitchen knives, industrial knives, and specialized blades for various applications.One of the key players in the Chinese knife and slitting knife industry is a leading manufacturer, known for its innovation, precision, and commitment to customer satisfaction. With state-of-the-art manufacturing facilities and a dedicated team of skilled professionals, the company has become a trusted name in the industry.The company specializes in the production of high-quality knives and slitting knives, catering to diverse industries such as paper, packaging, printing, and textiles, among others. Their range of products includes circular knives, straight knives, slitting blades, and perforating blades, each designed to deliver impeccable performance and durability. By utilizing cutting-edge technology and adhering to strict quality control measures, they ensure that every product meets the highest standards of excellence.In addition to their commitment to quality, the company is also committed to environmental sustainability. They employ environmentally friendly manufacturing processes and materials, reducing their carbon footprint and contributing to a greener world. By embracing sustainability, they have positioned themselves as a forward-thinking organization capable of meeting the demands of a rapidly changing world.The global demand for knives and slitting knives has been steadily increasing over the years. With advancements in various industries and the rise of e-commerce, there is a growing need for efficient cutting tools that can handle a wide range of materials. Chinese manufacturers, with their expertise and experience in the field, are poised to seize this opportunity and cater to the global market.The company aims to expand its presence in international markets by establishing strategic partnerships and collaborations. Through extensive market research and in-depth understanding of consumer needs, they are continuously developing new products and improving existing ones to meet the evolving demands of their global clientele.As the world becomes increasingly interconnected, the knife and slitting knife industry in China will continue to play a vital role in shaping global trade. With a focus on innovation, quality, and sustainability, Chinese manufacturers are well-positioned to drive the industry forward and contribute to the economic prosperity of the nation.In conclusion, the knife and slitting knife industry in China is set to flourish as global demand rises. With a rich history, commitment to quality, and focus on sustainability, Chinese manufacturers are poised to capitalize on the growing need for cutting tools. By leveraging their expertise and continuously innovating, they are well-equipped to meet the demands of diverse industries across the globe. As the industry continues to drive economic growth, China's reputation as a leading provider of high-quality knives will only strengthen, further solidifying its position in the global market.

Customizable Cemented Carbide Cutter Blades and Tungsten Carbide Knives for Tip MAT Cutting Blades

Title: Enhance Precision and Efficiency with Tungsten Carbide Knives and Cemented Carbide Cutter Blades in ChinaIntroduction:In today's world, precision and efficiency are key factors in various industries, from manufacturing to construction. One critical component that ensures smooth operations and precise cuts is the Tip MAT Cutting Blade. This blog will delve into the world of Tungsten Carbide Knives and Cemented Carbide Cutter Blades, explaining their significance, applications, and why they are the preferred choice in China's industrial landscape.1. Understanding Tungsten Carbide Knives:Tungsten Carbide Knives, renowned for their exceptional hardness, durability, and wear resistance, have become a cornerstone in many industries. These knives are composed of a combination of premium-quality tungsten carbide and a bonding metal, usually cobalt or nickel. The hardness of tungsten carbide allows it to withstand high temperatures and extreme pressures, making it an excellent choice for cutting applications.2. Versatility in Cemented Carbide Cutter Blades:Cemented Carbide Cutter Blades, often referred to as tungsten carbide blades, are highly versatile due to their outstanding cutting capabilities. They are utilized in numerous industries such as paper, textile, plastic, metalworking, and more. These blades not only offer superior cutting performance but also ensure extended productivity and reduced maintenance costs.3. Customized Solutions for a Perfect Fit:The Chinese market offers a wide range of Cemented Carbide Cutter Blades in regular sizes. However, manufacturers also have the provision to supply customized Tungsten Carbide Knives as per customer specifications. By submitting your inquiry, you provide precise demands in terms of size, design, and performance requirement, enabling manufacturers to cater to your unique needs effectively.4. Applications and Benefits:4.1 Textile Industry: Tungsten Carbide Knives and Cemented Carbide Cutter Blades find extensive use in the textile sector due to their ability to cut fibers, threads, and woven materials with accuracy, resulting in enhanced production rates and improved fabric quality.4.2 Packaging Industry: These blades are crucial in the packaging industry, precisely cutting various packaging materials like cardboard, plastic, and paperboard. They deliver clean cuts, prevent product damages, and ensure packaging precision.4.3 Metalworking Industry: Tungsten Carbide Knives excel in the metalworking industry, enabling effortless cutting of different metals and alloys. Their superior wear resistance ensures prolonged blade life, allowing increased productivity and minimized downtime.4.4 Woodworking Industry: Cemented Carbide Cutter Blades offer precise and efficient wood cutting solutions. They slice through hardwoods, softwoods, laminates, and composite boards effortlessly, creating clean and accurate cuts, minimizing wastage, and optimizing output.5. Why Choose Carbide Cutter Blades?5.1 Exceptional Durability: Carbide Cutter Blades possess remarkable wear resistance and withstand extreme temperatures, ensuring longevity and reduced replacement costs.5.2 Enhanced Efficiency: These blades provide clean, precise cuts, resulting in minimal material waste, increased productivity, and improved product quality.5.3 Cost-effectiveness: Although initially pricier than conventional blades, the long-lasting performance and reduced maintenance requirements make Carbide Cutter Blades a cost-effective investment in the long run.Conclusion:In the world of precision cutting, Tungsten Carbide Knives and Cemented Carbide Cutter Blades stand tall as game-changers. Especially in China's industrial domain, these superior blades are extensively utilized, guaranteeing precision, efficiency, and customer satisfaction. Whether you require off-the-shelf sizes or customized solutions, the Chinese market caters to all your demands, ensuring your cutting needs are met comprehensively. Choose Carbide Cutter Blades and experience an unparalleled cutting revolution!

Discover the Ultimate Double Blade Razor for an Effortless Shave

Title: The Perfect Shave - Discovering the Best Double Blade Razor in the MarketIntroduction:In the world of grooming, a smooth and comfortable shave is the epitome of a well-groomed individual. The hunt for the perfect razor has always been a challenge, with countless brands promising superior performance. However, one brand has consistently set the benchmark for excellence in shaving technology – the Best Double Blade Razor (*brand name removed*). Combining cutting-edge innovation with a rich heritage, this razor has earned its reputation as the go-to choice for those seeking the ultimate shaving experience.Fostering Tradition and Innovation:As a company with a longstanding history in the grooming industry, (*brand name removed*) has continued to evolve and adapt to the changing needs of consumers. Established with a mission to revolutionize the shave, the company has consistently delivered exceptional quality and performance. By combining traditional craftsmanship with state-of-the-art technology, (*brand name removed*) has developed a double blade razor that sets the standard for precision, comfort, and durability.Precision Engineering for Optimal Results:The Best Double Blade Razor by (*brand name removed*) embodies an unrivaled commitment to precision engineering. Each razor is carefully crafted using high-quality materials to ensure exceptional performance. The dual-blade design allows for a close and comfortable shave, effortlessly gliding over the contours of the face to provide an impeccably smooth finish. With meticulous attention to detail, the razor blades are meticulously sharpened, guaranteeing a precise and consistent shave every time.Superior Shaving Experience:(*brand name removed*) has taken every aspect of the shaving experience into consideration. The ergonomic handle of the Best Double Blade Razor ensures a comfortable grip, allowing for precise control even in hard-to-reach areas. The razor's advanced pivot technology adapts to the facial contours, providing a seamless glide and minimizing irritation. Whether it's a quick touch-up or a more detailed grooming routine, (*brand name removed*)'s double blade razor delivers a superior and effortless shaving experience.Uncompromised Safety and Durability:Safety is of paramount importance with (*brand name removed*). The Best Double Blade Razor incorporates safety features such as a protective guard to minimize the risk of nicks and cuts. Furthermore, the razor's durable construction ensures its longevity, allowing for extended use without compromising its shaving performance. By prioritizing safety and durability, (*brand name removed*) gives customers peace of mind while guaranteeing a superior shave for years to come.Consumer Satisfaction:The success of (*brand name removed*), lies in its unwavering commitment to customer satisfaction. Each razor undergoes rigorous testing to ensure the highest quality standards are met. Customer feedback and preferences are carefully considered during the design process, allowing (*brand name removed*) to continuously refine and improve its product offerings. It is this dedication to providing an exceptional shaving experience that has made (*brand name removed*) a trusted choice among consumers worldwide.Conclusion:(*Brand name removed*)'s Best Double Blade Razor truly stands out as a testament to the company's commitment to innovation, quality, and customer satisfaction. Through precision engineering, advanced technology, and a focus on safety and durability, (*brand name removed*) has redefined the shaving experience. As individuals strive to achieve the perfect shave, the Best Double Blade Razor by (*brand name removed*) emerges as the unrivaled choice for those seeking superior performance and uncompromising quality.

The Advantages of a Tungsten Carbide Knife Revealed in Latest News

Tungsten Carbide Knife: Revolutionizing Precision CuttingIn recent years, the field of precision cutting has witnessed astounding advancements. One such innovation is the Tungsten Carbide Knife, a cutting-edge tool that has revolutionized various industries. With its exceptional durability, sharpness, and versatility, this remarkable blade has quickly become the go-to choice for professionals in fields ranging from aerospace engineering to surgical procedures.The Tungsten Carbide Knife, a remarkable creation of multiple cutting-edge technologies, is composed of tungsten carbide, a hard and dense material that exhibits immense strength and resistance to wear. This unique combination of strength and durability makes it perfect for applications that require sustained high-performance cutting.What sets the Tungsten Carbide Knife apart from other cutting tools is its exceptional sharpness. With a hardness level close to that of a diamond, this knife boasts an unbeatable cutting edge that remains sharper for longer compared to traditional blades. This sharpness not only ensures precision and accuracy in every cut but also eliminates the need for constant sharpening, saving both time and costs for its users.Moreover, the versatility of the Tungsten Carbide Knife is another factor contributing to its widespread adoption across various industries. Whether it be slicing through tough materials like steel or delicate procedures such as intricate surgical incisions, this revolutionary blade can handle it all. Its adaptability has made it indispensable in fields like aerospace engineering, metal fabrication, woodworking, and even culinary arts.The aerospace industry has greatly benefited from the Tungsten Carbide Knife's exceptional cutting performance. During the manufacturing process of aircraft components, precision is of utmost importance to ensure the safety and integrity of the final product. The sharpness and durability of this knife make it an invaluable tool for cutting materials like carbon fiber composites and titanium alloys with utmost precision and efficiency.Metal fabricators have also found the Tungsten Carbide Knife to be a game-changer. It enables them to effortlessly cut through hardened steel, reducing production time and improving overall efficiency. Additionally, its long-lasting sharpness minimizes the need for blade replacements or frequent resharpening, resulting in significant cost savings.Woodworking enthusiasts have also hailed the Tungsten Carbide Knife as one of the most essential tools in their repertoire. Its ability to cut through various types of wood with precision and ease allows craftsmen to create intricate designs and achieve exceptional finishes. The durability of the blade ensures that it can handle prolonged use, even on denser wood species, without losing its sharpness or structural integrity.In the field of medicine, the Tungsten Carbide Knife has become a staple tool for surgeons performing intricate procedures. Its outstanding sharpness and resistance to wear enable precise incisions, reducing the risk of tissue damage and minimizing patient recovery time. Furthermore, the knife's resistance to corrosion ensures that it can be safely sterilized for reuse, providing a cost-effective solution for hospitals and medical facilities.As demand for precision cutting solutions continues to rise, manufacturers have capitalized on the potential of the Tungsten Carbide Knife. Companies such as [Company Name] have honed their expertise in producing these exceptional blades, combining cutting-edge technologies with intricate craftsmanship. From material selection to the final finishing, every step of the manufacturing process at [Company Name] ensures that their Tungsten Carbide Knives meet the highest standards of quality and performance.With dedicated research and development efforts, [Company Name] continuously pushes the boundaries of what is possible with the Tungsten Carbide Knife. By incorporating user feedback and advanced manufacturing techniques, they strive to improve the blade's performance, lifespan, and versatility. As a result, [Company Name] has become a trusted name in the industry, providing professionals across various fields with reliable and exceptional cutting solutions.In conclusion, the Tungsten Carbide Knife has revolutionized precision cutting in multiple industries. Its unparalleled durability, sharpness, and versatility have made it the go-to tool for professionals in aerospace engineering, metal fabrication, woodworking, and medicine. Manufacturers like [Company Name] have played a crucial role in the widespread adoption of this remarkable blade, constantly pushing the boundaries of its capabilities. As technology continues to advance, we can expect the Tungsten Carbide Knife to further evolve, revolutionizing precision cutting even more in the years to come.

Discover the Advantages of Tire Shredders - Efficiently Shred Various Materials for Recycling

: A Comprehensive GuideWhen it comes to reducing the size of wood waste, a wood shredder is an indispensable piece of equipment in any wood processing facility. The machine grinds large pieces of wood into small particles, making it easier and more efficient to transport and dispose of. In this article, we will discuss the features of wood shredders, their price movement and sales, and the Hengzhou Shuguang Heavy Machinery Co., Ltd. tire shredder.Features of Wood ShreddersWood shredders come in various sizes and shapes, but most of them share a common set of features that make them capable of handling different types of wood waste. These features include:1. Single Spindle CrusherThis feature allows wood shredders to break down large parts of powder basket pipe board wood tires, scrap metal barrel, a large roll film, and other kinds of wood waste. The single spindle crusher reduces the size of the wood waste to a manageable size, making it easier to transport and dispose of.2. High Plate PrecisionThe combination structure of a high plate precision facilitates the efficient and cost-effective shredding of wood waste. A high plate precision ensures that the machine operates smoothly and performs well, even when working on hardwoods or thicker wood material.Wood Shredder Price MovementThe price of wood shredders varies depending on the machine's size, features, and performance. A small wood shredder costs around $500 to $1,500, while a commercial-grade shredder costs $10,000 or more. As demand for wood shredders rises, so does the price. However, with the increasing adoption of efficient wood shredders, the price is likely to stabilize in the long run.Wood Shredder SalesWood shredders are widely used in various industries, which drives demand for these machines. Some of the significant industries that use wood shredders include wood processing facilities, paper mills, lumberyards, and biomass energy plants. The increasing adoption of wood shredders is expected to enable these industries to reduce the time and cost of wood processing.Hengzhou Shuguang Heavy Machinery Co., Ltd. Tire ShredderHengzhou Shuguang Heavy Machinery Co., Ltd. is a leading manufacturer of tire shredders. The tire shredder has several features that make it unique, including:1. High OutputThe tire shredder has a high output capacity that enables it to process a large number of tires within a short period.2. Low Energy ConsumptionThe tire shredder uses a low amount of energy to operate, making it cost-effective and energy-efficient.3. High AutomationThe tire shredder is fully automated, taking only a few minutes to shred a tire into small pieces.In conclusion, wood shredders are essential machines in wood processing facilities, enabling efficient processing of wood waste. With their various features, these machines can handle different types of wood scrap, reducing the cost and time spent on processing wood. As of the price movement, the price of wood shredders is likely to increase in the short term, but it will stabilize as the adoption of these machines grows.

New Precision Cutting Disc Technology Shifting the Industry Standard" becomes "Revolutionary Precision Cutting Disc Tech Changes Industry Norms

Title: Industry Leader Launches Cutting-Edge Cutting Disc Solution for Enhanced Precision and Efficiency Introduction:{Company Name}, a renowned global manufacturing company specializing in innovative industrial tools, has announced the release of its latest innovative product, the cutting disc. With decades of experience and expertise in the industry, {Company Name} has consistently led the market in developing cutting-edge solutions to address the evolving needs of professionals across various sectors.Innovative Features and Technology:The new cutting disc by {Company Name} sets new industry standards by offering a comprehensive range of features and cutting-edge technology. Incorporating state-of-the-art materials and precision engineering, this cutting disc ensures exceptional performance, prolonged durability, and enhanced cutting efficiency.One of the key innovations of this cutting disc lies in its unique composition. Made from a combination of high-quality abrasives and reinforced resin, this advanced disc delivers exceptional precision cutting without compromising on durability. Designed to resist heat and wear during demanding applications, the cutting disc guarantees long-lasting performance, making it an ideal tool for professionals in heavy industries such as automotive, construction, and manufacturing.Unparalleled Precision:{Company Name}'s cutting disc is specifically engineered to provide maximum precision, enabling professionals to achieve the most accurate cuts possible. The meticulous craftsmanship and rigorous quality control measures employed during the manufacturing process guarantee unparalleled consistency in thickness, diameter, and overall cut.The advanced technology utilized in the production of the cutting disc ensures reduced vibration, thereby minimizing the risk of user fatigue and ensuring a safe and comfortable working environment. Users can rely on this cutting disc for smooth, straight, and clean cuts across a wide range of materials, including metal, stainless steel, aluminum, and more.Optimized Efficiency and Productivity:{Company Name}'s cutting disc is meticulously designed to optimize efficiency and productivity in the workplace. The disc's unique composition and superior manufacturing process result in reduced cutting time and improved overall performance. With this cutting disc, professionals can complete their tasks efficiently while achieving outstanding accuracy.Additionally, this cutting disc offers remarkable versatility, adapting to a variety of cutting applications. Its compatibility with different tools, including angle grinders and power saws, further enhances its usability and makes it a preferable choice across various industries.Commitment to Safety:{Company Name} prioritizes the safety of its customers, and this commitment is evident in the design and manufacturing process of its cutting discs. Every disc undergoes rigorous quality control tests to ensure compliance with the highest safety standards. The cutting disc's advanced features and enhanced durability minimize the risk of accidents, providing users with a reliable and secure cutting solution.Conclusion:As {Company Name} launches its cutting disc into the market, professionals from various industries can look forward to experiencing a new standard of precision, efficiency, and durability. With its superior cutting performance, advanced technology, and commitment to safety, this cutting disc will undoubtedly become an indispensable tool in the toolbox of professionals around the world.