Industrial rotary files: A game-changer for metalworking tasks

By:Admin

Carbide Rotary Files have become an increasingly popular tool among manufacturers in recent years owing to the many advantages that they offer. They are highly versatile and are used in a variety of applications, ranging from shaping hard metals to creating intricate designs in plastics and wood. They can be used to cut, grind, deburr, shape, and finish a wide range of materials with precision and ease. Carbide Rotary Files are made using high-quality tungsten carbide, which ensures that they are highly durable, long-lasting, and can withstand heavy usage.

The Carbide Rotary File is becoming an especially popular tool among manufacturers looking for a faster way to remove material during prototyping and production runs. The tool is capable of carving through metal, composites, wood, and other materials without breaking or dulling quickly, thus saving on downtime. With its speed and efficiency, it can help manufacturers achieve their desired product shape or design in a fraction of the time taken by traditional tools.

Its popularity among the manufacturing community has been growing steadily ever since the Carbide Rotary File was introduced. There are several reasons why this tool is becoming increasingly preferred by manufacturers. Firstly, the Carbide Rotary Files are highly versatile. They can be used on a wide range of materials, including steel, aluminum, wood, and plastic, among others. Secondly, they are highly durable and can withstand heavy usage without breaking or dulling. This ensures that manufacturers can use the same file for multiple applications, which saves both time and money. Lastly, the Carbide Rotary Files are easy to use and can be operated by almost anyone without any specialized training or experience.

In light of the growing demand for Carbide Rotary Files, several companies have started to manufacture and supply these tools. One such company is a leading supplier of cutting tools based in the United States that offers a wide range of Carbide Rotary Files. The company has over 30 years of experience in the cutting tool industry and has a proven track record of delivering high-quality tools to its clients.

The Carbide Rotary Files manufactured by this company are highly rated by users and have received rave reviews. The company uses only the highest quality tungsten carbide to ensure that its files are durable, long-lasting, and can withstand heavy usage. The products are designed to offer maximum flexibility and precision while working with a variety of metals, ceramics, plastics, and composites.

The company is also known for its exceptional customer service. It offers timely deliveries and ensures that its customers are satisfied with their orders and the products received. The company also provides routine maintenance for their tools to keep them in good condition and ensure they function optimally.

In conclusion, the Carbide Rotary File is an essential tool for modern-day manufacturers looking for a faster and more efficient way of removing material during the prototyping and production processes. These files provide unparalleled flexibility, precision, and durability, making them an ideal solution for cutting, grinding, deburring, shaping, and finishing a wide range of materials. The Carbide Rotary Files offered by the leading supplier of cutting tools in the United States exemplify the latest in innovation and are being widely adopted by manufacturers across the globe.

Company News & Blog

Browse High-Quality Planer Blades and Accessories for Your Woodworking Needs

article about the importance of using high-quality planer blades for woodworking projects.As a woodworking professional, you understand the importance of using high-quality tools and equipment to achieve accurate and precise results. That's why investing in the right planer blades is essential to achieving superior quality output in every project.Planer blades are among the most critical tools in your arsenal for handling woodworking projects. These tools are responsible for shaping and leveling wood surfaces, which is why you need to choose the best planer blades for your applications.Here, we'll take a closer look at the importance of using high-quality planer blades in woodworking and how they can improve your output.PrecisionOne of the main advantages of using high-quality planer blades is precision. Good quality blades are precise and can achieve smoother, more even finishes. This precision can be essential when dealing with delicate or intricate wood pieces that require the utmost care.Reversible and Spiral BladesPROTRADE offers a range of planer blades for every woodworking need, including spiral and reversible blades. Reversible blades are versatile and can be flipped over for a fresh cutting edge, extending the life of the blade. They're also easy to replace, making them an excellent choice for woodworking professionals.Spiral blades, on the other hand, provide a superior cut surface quality, which is essential for high-end woodworking projects that require fine detail. Spiral blades offer great cutting performance and last longer than standard straight knives.DurabilityHigh-quality planer blades are made from high-quality materials, making them more durable than inferior blades. Durable blades are particularly advantageous in commercial woodworking shops where blades are used frequently and need to be replaced regularly.Using high-quality blades can also help prevent the need for frequent sharpening and blade replacements. This can be especially important for larger or more complex woodworking projects where efficient work and longer-lasting blades are crucial.Material CompatibilityDifferent materials and applications can require specific types of planer blades, which is another reason why it's essential to choose high-quality blades. Depending on the material you are workworking with, the blade's angle, length, and design will have an effect on the final output of your project.For instance, solid wood requires different blade designs compared to plywood or MDF. For harder or denser materials where more power is required, a blade with a steeper cutting angle may be required, while woods with a patterned grain may need blades with a shallower angle.In ConclusionIn summary, using high-quality planer blades can significantly enhance the quality of every woodworking project you undertake. Investing in the right blades, from high-quality brands like Festool and Virutex (remove brand name), is essential to achieving precise, even finishes and extending the life of your equipment.Whether you're a seasoned professional or just starting, using high-quality planer blades from PROTRADE can make a significant difference in the quality of your work. So why not upgrade your equipment today and see the difference for yourself?

New Precision Cutting Disc Technology Shifting the Industry Standard" becomes "Revolutionary Precision Cutting Disc Tech Changes Industry Norms

Title: Industry Leader Launches Cutting-Edge Cutting Disc Solution for Enhanced Precision and Efficiency Introduction:{Company Name}, a renowned global manufacturing company specializing in innovative industrial tools, has announced the release of its latest innovative product, the cutting disc. With decades of experience and expertise in the industry, {Company Name} has consistently led the market in developing cutting-edge solutions to address the evolving needs of professionals across various sectors.Innovative Features and Technology:The new cutting disc by {Company Name} sets new industry standards by offering a comprehensive range of features and cutting-edge technology. Incorporating state-of-the-art materials and precision engineering, this cutting disc ensures exceptional performance, prolonged durability, and enhanced cutting efficiency.One of the key innovations of this cutting disc lies in its unique composition. Made from a combination of high-quality abrasives and reinforced resin, this advanced disc delivers exceptional precision cutting without compromising on durability. Designed to resist heat and wear during demanding applications, the cutting disc guarantees long-lasting performance, making it an ideal tool for professionals in heavy industries such as automotive, construction, and manufacturing.Unparalleled Precision:{Company Name}'s cutting disc is specifically engineered to provide maximum precision, enabling professionals to achieve the most accurate cuts possible. The meticulous craftsmanship and rigorous quality control measures employed during the manufacturing process guarantee unparalleled consistency in thickness, diameter, and overall cut.The advanced technology utilized in the production of the cutting disc ensures reduced vibration, thereby minimizing the risk of user fatigue and ensuring a safe and comfortable working environment. Users can rely on this cutting disc for smooth, straight, and clean cuts across a wide range of materials, including metal, stainless steel, aluminum, and more.Optimized Efficiency and Productivity:{Company Name}'s cutting disc is meticulously designed to optimize efficiency and productivity in the workplace. The disc's unique composition and superior manufacturing process result in reduced cutting time and improved overall performance. With this cutting disc, professionals can complete their tasks efficiently while achieving outstanding accuracy.Additionally, this cutting disc offers remarkable versatility, adapting to a variety of cutting applications. Its compatibility with different tools, including angle grinders and power saws, further enhances its usability and makes it a preferable choice across various industries.Commitment to Safety:{Company Name} prioritizes the safety of its customers, and this commitment is evident in the design and manufacturing process of its cutting discs. Every disc undergoes rigorous quality control tests to ensure compliance with the highest safety standards. The cutting disc's advanced features and enhanced durability minimize the risk of accidents, providing users with a reliable and secure cutting solution.Conclusion:As {Company Name} launches its cutting disc into the market, professionals from various industries can look forward to experiencing a new standard of precision, efficiency, and durability. With its superior cutting performance, advanced technology, and commitment to safety, this cutting disc will undoubtedly become an indispensable tool in the toolbox of professionals around the world.

Circular Blades for Cigarette Filter Rod Cutting - Tungsten Carbide Knives

Kunshan Dekaisheng Edge Mold Co. Ltd. is a reputable company that specializes in the production of circular cutting knives. The company has been in existence for many years and is well-known for producing high-quality products that meet the needs of its numerous clients. One of the most popular products manufactured by the company is the 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives.The cigarette filter is an essential part of cigarette production, and it helps to reduce the harmful effects of smoking on human health. One of the critical processes involved in cigarette production is cutting the cigarette filter rod. This is where the 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives come in handy.These circular cutting knives are made of tungsten carbide material, which makes them tough and durable. Tungsten carbide is known for its excellent wear resistance, high melting point, and strength. Therefore, it is the most suitable material for the production of circular cutting knives that can withstand the rigorous and demanding requirements of cigarette filter rod cutting.The regular size of slitting knives is OD88xID16xTHK0.26mm, which is the perfect dimension for the cutting of cigarette filter rods. The blades are sharp and accurate, and they can cut the filter rod to the desired size and shape with ease. The precision of the knives is crucial because it ensures that the filter is cut to the right size, and it fits perfectly into the cigarette.The 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives produced by Kunshan Dekaisheng Edge Mold Co. Ltd. are of high quality and meet the standards set by the industry. The company uses the latest technology in the production of its products, and it employs experienced professionals who understand the intricacies of the industry.Regardless of the size of your order, Kunshan Dekaisheng Edge Mold Co. Ltd. can deliver the knives within the stipulated time frame. The company has excellent logistics and supply chain management, ensuring that its customers get their orders promptly and without delay. The company also provides excellent customer support services and offers aftersales services to ensure customer satisfaction.In conclusion, the 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives produced by Kunshan Dekaisheng Edge Mold Co. Ltd. is the most suitable tool for cutting cigarette filter rods. The company's reputation for producing high-quality products is well-known, and it has a track record of delivering orders promptly to its customers. If you are in the cigarette production industry and need a reliable supplier of circular cutting knives, then Kunshan Dekaisheng Edge Mold Co. Ltd. is the right choice for you.

Durable Plastic Grinding Blades Made for Tough Shredding Operations

Plastic Grinder Blade - A Revolutionary Innovation in the World of Plastics RecyclingPlastics have been an integral part of our life for decades. From the simplest of products like toys, containers, bags, and bottles to the most intricate of machinery components, plastics have found multiple applications in various industries. However, with the rapid growth in the consumption of plastics, the problem of plastic waste has also witnessed an unprecedented surge. In recent years, there has been a growing concern about the impact of plastic waste on the environment and the need for its proper disposal and recycling. One of the most effective ways to handle plastic waste is by shredding and granulating it with the help of Plastic Grinder Blades.Among the different types of plastic processing blades, the Plastic Grinder Blade is considered to be one of the most efficient and versatile. The blade has a unique design that allows it to shred plastic waste into small, consistent particles that can be easily processed further. This particular processing blade is a revolutionary innovation in the world of plastics recycling, thanks to its precision engineering and the use of advanced materials.One of the key manufacturers of Plastic Grinder Blades is a renowned company in the industry, with a rich legacy of over 30 years. The company has a strong presence in the global market and is known for its high-quality products and exceptional customer service. The company's commitment to innovation and R&D has earned it a reputation as a pioneering force in the field of plastic processing blades.The Plastic Grinder Blades offered by the company are made of premium-grade materials that ensure exceptional durability and longevity. These blades are specially designed to handle various types of plastic waste, including hard and soft plastics, films, fibers, and more. The blades are available in different sizes and configurations, allowing customers to choose the right blade for their specific requirement.One of the key advantages of using Plastic Grinder Blades is that they offer a highly efficient way to process plastic waste. Unlike traditional methods of plastic waste disposal, which involve landfill or incineration, shredding and granulating plastics can significantly reduce their volume and make them easier to transport and store. Moreover, the shredded plastic material can be easily reused or recycled to create new products, reducing the burden on the environment and conserving natural resources.Another advantage of using Plastic Grinder Blades is that they are versatile and can be used to process a wide range of plastic waste. Whether it is post-consumer waste, industrial waste, or scrap material, the blades can effectively shred and granulate it into small particles. This makes them an ideal choice for various industries, including plastics recycling, packaging, electronics, automotive, and more.The Plastic Grinder Blades offered by the company are not only high-quality and efficient, but they are also affordable. The company offers competitive pricing for its products, making them accessible to a wide range of customers. The company also provides excellent after-sales support, ensuring that customers get the most out of their investment.In conclusion, Plastic Grinder Blades are a revolutionary innovation in the world of plastics processing and recycling. They offer a highly efficient and cost-effective way of handling plastic waste, making them an ideal choice for various industries. With the expertise and experience of one of the leading manufacturers of plastic processing blades, customers can be assured of high-quality and durable products that will meet their specific requirements.

Revolutionary Carbide Disposable Insert: Discover the Latest Advancements in Cutting Technology

Carbide Disposables – Revolutionizing the Industrial Manufacturing ProcessIn the industrial manufacturing process, the production of high-quality precision components requires the use of cutting-edge technology and the right tools. One critical component in this respect is Carbide Disposables, which have revolutionized the way manufacturers approach their manufacturing processes. Carbide Disposables are a type of cutting tool that is made with carbide, a type of material that is known for its durability and wear resistance.Carbide Disposables are used in various industrial applications, including woodworking, metalworking, and automotive manufacturing. They have become increasingly popular among manufacturers due to their superior cutting performance and extended durability. When compared to traditional steel or high-speed steel cutting tools, Carbide Disposables have a longer lifespan and can cut through materials with a higher degree of precision.As a market leader in the production of Carbide Disposables, our company has a proven track record in manufacturing the highest-quality cutting tools for industrial applications. Our company has been producing cutting tools since the early 1970s and has remained at the forefront of technological advancements in the industry. Our Carbide Disposables product line is a result of years of dedicated research and development, and our cutting-edge manufacturing process ensures that our tools are of the highest quality.Our Carbide Disposables are designed for a range of industrial applications and are available in various shapes and sizes. Our products are designed to meet the needs of customers across different industries, and we offer customized solutions to ensure that our customers get the best tools to fit their specific requirements. Our Carbide Disposables are made using the latest sintering and centerless grinding technologies, which means that they are precision-engineered and have incredibly consistent cutting performance.One of the biggest benefits of using Carbide Disposables is that they require less maintenance when compared to other cutting tools. This is because carbide is incredibly durable and wear-resistant, which means that our Carbide Disposables last longer than conventional cutting tools. This translates into a significant cost-saving for our customers as they do not have to replace cutting tools as frequently.Our Carbide Disposables are not just durable and long-lasting, they also offer superior cutting performance. This is because carbide is a harder material than steel, which means that it can cut through tougher materials with greater ease. Additionally, our Carbide Disposables are made with a precision-ground edge, which ensures that they cut through materials with a higher degree of accuracy. This translates into less waste material and increased efficiency in the manufacturing process.In conclusion, Carbide Disposables have revolutionized the industrial manufacturing process by offering superior cutting performance, enhanced durability, and reduced maintenance requirements. Our company's Carbide Disposables product line is a market leader in the industry, and we pride ourselves in offering customized solutions that meet the needs of our customers. Our Carbide Disposables are a testament to our company's commitment to excellence in manufacturing, and we will continue to develop new and innovative products to meet the evolving needs of the industrial manufacturing sector.

Top Picks for Heavy-Duty Carpet Knife Blades with Promotions

When it comes to carpet installation, one of the most overlooked tools is the carpet knife blade. This may seem like a small part of the entire process, but choosing the right blade can significantly impact the efficiency, safety, and quality of your work. In this blog, we will take a closer look at the Heavy Duty Carpet Blades, particularly Stanley's 11-530, and its features, benefits, and possible drawbacks.The Stanley 11-530 Heavy Duty Carpet Blades come in a box of 100, making it a cost-effective option for contractors or DIY enthusiasts who frequently handle carpeting tasks. As its name suggests, this blade is designed for heavy-duty applications, so it can slice through thick and dense carpets with ease. The blade measures 2-1/2 inches in length and features a sharpened, precision-honed edge that maintains its sharpness well.One of the standout features of the Stanley 11-530 is its durability. The blade is made from high-carbon steel, which is known for its toughness and resistance to corrosion. This means that you won't have to replace the blade as often as other models, saving you time and money in the long run. The blade is also coated with lacquer to prevent rust formation, so you can be sure that it will stay in good condition even after prolonged use.Another benefit of the Stanley 11-530 Heavy Duty Carpet Blades is its compatibility with various carpet knives. Whether you have a retractable, fixed, or snap-off blade knife, this blade can fit perfectly and secure, thanks to its notched design that prevents slipping or accidental dislodgment. Furthermore, the Stanley 11-530 is designed for easy blade replacement, so you don't have to fumble or use force to switch blades during a project.Speaking of safety, the Stanley 11-530 is also designed with user protection in mind. The blade features rounded edges and a rounded tip, which reduces the risk of accidental cuts or punctures. This is especially important when working on intricate or challenging carpeting tasks that require precision and focus. Additionally, the blade comes with a storage case that keeps the unused blades secure and out of reach of children or pets.Of course, no product is perfect, and the Stanley 11-530 Heavy Duty Carpet Blades are no exception. One of the main drawbacks of this blade is its weight. Some users may find it heavier than other carpet blades, especially when used for extended periods. However, this may also be a testament to its durable construction, as heavier blades are often made of sturdier materials such as high-carbon steel.Overall, the Stanley 11-530 Heavy Duty Carpet Blades are an excellent choice for professionals or DIYers who want a reliable and robust blade for their carpeting jobs. Its durability, compatibility, and safety features make it a worthwhile investment that can improve the quality of your work while keeping you safe. If you're looking for Heavy Duty Carpet Blades that can withstand even the toughest carpeting tasks, give the Stanley 11-530 a try.

Reversible Screwdriver Blade for Maximum Durability - Phillips #2 + Slotted 6.0mm

for Precision Work, Wiha Phillips #2 Screwdriver Blade, Drive-Loc Handles, Collet Lock Handles, and Made in Germany.When it comes to working on delicate or intricate projects, having the right tools can make all the difference. That's why it's important to invest in high-quality blades like the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade.This blade is designed for use with both Drive-Loc and Collet Lock handles, giving you versatility in your toolkit. The blades are made from premium tool steel that has been through hardened and finished for maximum durability. This means you can rely on them to hold up to heavy use without losing their sharpness.One of the standout features of this blade is its double-ended design. With both a Phillips #2 screwdriver blade and a slotted 6.0mm (15/64") blade, you can easily switch between tasks without switching tools. This saves you time and effort, making it an ideal choice for professionals and DIY enthusiasts alike.As with all Wiha products, this blade is made in Germany to the highest standards of quality. You can trust that it will last you for years to come and give you excellent performance every time you use it.Whether you're working on precision electronics, appliances, or other household items, the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade is a must-have in your toolkit. Its high-quality slotted blades make it perfect for precision work, and its compatibility with Drive-Loc and Collet Lock handles make it a versatile choice for any project.Investing in the best tools means investing in top-quality blades like the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade. Add it to your toolkit today and experience the difference a high-quality blade can make.

Custom Blades for Textile Cutting: Find the Perfect Fit for Your Application

In today's world, technology has influenced every aspect of our daily lives, including the textile industry. Custom machine knives for cutting textiles are essential for the creation of high-quality textiles quickly and accurately. York Saw is a renowned manufacturer of industrial blades that can be customized to fit specific textile cutting applications. Their expertise and capabilities make them an ideal partner for textile manufacturers looking to improve their operations.York Saw has been a leader in the blade industry for over 100 years. Their experience and knowledge of blade manufacturing has allowed them to create some of the most durable and reliable blades in the market. Their quality control measures ensure that their products perform to the highest standards for years to come.The importance of precise cutting in the textile industry cannot be overemphasized. When it comes to cutting fabric, accuracy and precision are crucial. In the past, manual cutting was the only option available. However, with technological advancements, the use of cutting machines has become the norm. These machines have revolutionized the textile industry by allowing for increased productivity, efficiency, and accuracy.The blades used in cutting machines play a vital role in determining the quality of fabric cut. The blade must be sharp and durable enough to cut through the fabric without causing any damage. If the blade is blunt or ineffective, it can cause significant issues, including jagged edges, uneven cuts and can even damage the fabric.York Saw provides high-quality industrial blades that are specifically designed for textile cutting applications. They offer a wide range of blades in different sizes, materials, thicknesses, and designs to meet the unique needs of each customer. The blades can be customized to suit the specific requirements of the textile manufacturer, including the material being cut, the thickness of the fabric, and the desired cutting speed. York Saw uses the latest technology to manufacture their blades, including automated machines that produce precise and accurate blades repeatedly. They also have an in-house team of experts that work with each customer to understand their unique needs and provide the appropriate solution. By working closely with their customers, they can develop a blade that meets their precise requirements and provides optimal performance, resulting in an increase in productivity and cost savings.In summary, York Saw is a leading manufacturer of industrial blades for textile cutting applications. Their commitment to quality, reliability, and precision has made them a trusted partner for textile manufacturers worldwide. They understand that every customer has unique needs, and they are dedicated to providing personalized solutions that meet their specific requirements. Their expertise and capabilities make them an ideal partner for anyone looking to improve their textile cutting operations. Contact York Saw today to learn more about how they can help with bespoke machine knives for cutting textiles.

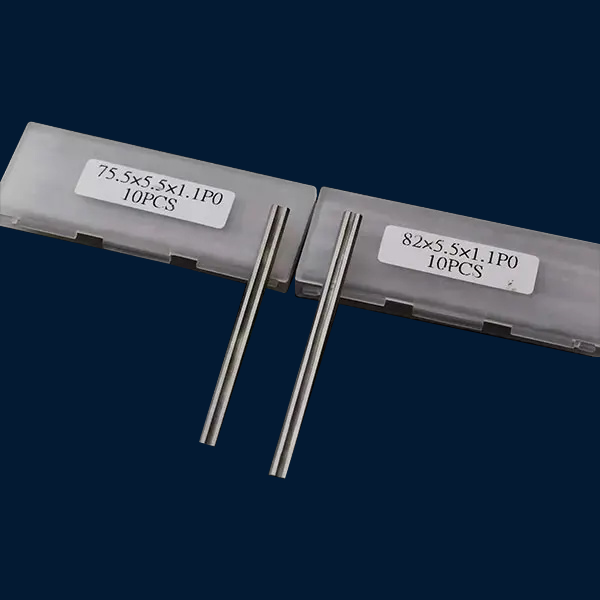

High-Performance 82mm Reversible Planer Blades: Enhance Your Woodworking Projects

Title: Innovative 82mm Reversible Planer Blades Set to Revolutionize Woodworking IndustryIntroduction:In the constantly evolving woodworking industry, achieving precision and efficiency in planing wood surfaces is of utmost importance. Addressing this need, a leading manufacturer, (Remove brand name) has recently launched its cutting-edge 82mm Reversible Planer Blades. This pioneering product is poised to redefine woodworking operations by offering unparalleled versatility, durability, and superior performance. In this article, we delve into the remarkable features of these planer blades and their potential impact on the woodworking industry.Section 1: Unmatched Versatility:The cornerstone of the 82mm Reversible Planer Blades' success lies in their adaptability to diverse woodworking projects. These blades are engineered to fit a wide range of planers, making them a versatile solution for professionals and hobbyists alike. Whether it is a large-scale commercial woodworking operation or a small DIY project, the reversible planer blades ensure an exceptional finish every time, regardless of the wood type or grain.Section 2: Advanced Technology:The 82mm Reversible Planer Blades boast cutting-edge technology that enables them to deliver precise planing results. The blades are manufactured using high-quality and hardwearing tungsten carbide, known for its exceptional strength and durability. This robust material allows the blades to withstand prolonged use without compromising on their effectiveness, ensuring an extended lifespan and cost-effectiveness for users.Section 3: Innovative Double-Edged Design:Another remarkable feature of these planer blades is their double-edged design, revolutionizing the woodworking process. By incorporating two sharp cutting edges on each blade, users can now achieve twice the work with minimal downtime for blade changes. This innovation not only saves valuable time and effort but also enhances the overall efficiency of woodworking projects, increasing productivity levels for professionals.Section 4: Enhanced Cutting Performance:The 82mm Reversible Planer Blades are carefully crafted to deliver outstanding cutting performance. Their razor-sharp edges enable them to effortlessly slice through wood, resulting in smooth and even surfaces that require minimal sanding. Moreover, the reusability of the blades further adds to their cost-effectiveness, as they can be flipped over multiple times before needing replacement.Section 5: User-Friendly Features:Recognizing the importance of user convenience, (Remove brand name) has integrated several user-friendly elements into the design of the 82mm Reversible Planer Blades. The blades come equipped with easy-to-use magnetic fittings that ensure a hassle-free installation process. This feature eliminates the need for complex tools and ensures a secure and stable blade fit, enhancing safety during operation.Section 6: Industry Impact and Customer Reviews:Since their introduction, the 82mm Reversible Planer Blades have garnered widespread acclaim from professionals in the woodworking industry. Woodworkers have praised the blades for their exceptional durability, versatility, and cutting precision. Many have reported significant improvements in their efficiency and productivity, attributing these advancements to the exceptional performance of the reversible blades. With such positive feedback, it is anticipated that these planer blades will soon become an industry standard worldwide.Conclusion:The release of the 82mm Reversible Planer Blades marks a significant milestone in the woodworking industry. The exceptional versatility, advanced technology, and user-friendly features of these blades will undoubtedly revolutionize the way woodworking projects are carried out. With their outstanding cutting performance and extended lifespan, these planer blades are set to become invaluable tools for professionals and enthusiasts alike. (Remove brand name)'s commitment to innovation has truly paved the way for a brighter future in the domain of woodworking.

High-Quality Doctor Blade for Paper Making Machines at a Competitive Price

Doctor Blade for Paper Making Machine: Leizhan Paper Machinery Co., Ltd Offers Superior Quality, High Performance and Efficient Doctor BladesLeizhan Paper Machinery Co., Ltd is a leading manufacturer and supplier of paper making machinery and equipment based in China. The company has been providing high-quality, efficient, and cost-effective solutions to paper mills' requirements across the globe. Leizhan Paper Machinery Co., Ltd understands the importance of precision and accuracy in the paper making process. That is why the company provides top-quality doctor blades to the customers to ensure maximum efficiency and productivity.Doctor blades are a crucial component of the paper making machine. The doctor blade is responsible for removing excess material or fibers from the surface of the paper roll. The process helps to ensure that the paper produced is of high quality and consistent. The quality of doctor blades determines the paper's quality and production efficiency. Leizhan Paper Machinery Co., Ltd provides doctor blades that meet the highest standards of quality. The doctor blades are made of high-quality materials, ensuring that they are durable and long-lasting.Leizhan Paper Machinery Co., Ltd offers doctor blades that can be used with a wide range of paper and board grades, including coated, uncoated, newsprint, and tissue paper. The doctor blades are designed to meet the specific needs of each paper mill, ensuring the highest level of precision and accuracy. At Leizhan Paper Machinery Co., Ltd, we understand that every paper mill has unique requirements and specifications. That's why our team of experts works closely with each customer to understand their needs and develop tailored solutions that meet their specific requirements.Leizhan Paper Machinery Co., Ltd has invested heavily in research and development to improve the performance and efficiency of doctor blades. The company has employed cutting-edge technologies to produce doctor blades that offer unmatched performance, quality, and durability. The doctor blades are designed to reduce wear and tear on the paper machine's components, resulting in a longer lifespan and lower maintenance costs.Leizhan Paper Machinery Co., Ltd's doctor blades are packed with features that make them stand out in the market. The blades are made of high-quality materials that are resistant to wear and tear even under harsh operating conditions. The blades are designed to have a sharp and consistent edge, ensuring that the paper produced is of high quality and consistent. The blades have a smooth and consistent surface that reduces friction and wear on the machine's components.Leizhan Paper Machinery Co., Ltd's doctor blades are highly efficient and can significantly improve the paper mills' overall productivity. The blades have a long lifespan, reducing the need for frequent replacement and maintenance. The blades are easy to install and use, making them an ideal solution for paper mills that want to improve their production efficiency and reduce their operating costs.In conclusion, Leizhan Paper Machinery Co., Ltd is a reputable and reliable supplier of doctor blades for paper making machines. The company offers superior quality, high performance, and efficient doctor blades that meet the highest standards of quality. The company's commitment to research and development has enabled it to produce doctor blades that offer unmatched performance, quality, and durability. If you are looking for doctor blades for your paper making machine, Leizhan Paper Machinery Co., Ltd is the ideal supplier to meet your needs.