- Home

- Blog

- Revolutionary Carbide Disposable Insert: Discover the Latest Advancements in Cutting Technology

Revolutionary Carbide Disposable Insert: Discover the Latest Advancements in Cutting Technology

By:Admin

In the industrial manufacturing process, the production of high-quality precision components requires the use of cutting-edge technology and the right tools. One critical component in this respect is Carbide Disposables, which have revolutionized the way manufacturers approach their manufacturing processes. Carbide Disposables are a type of cutting tool that is made with carbide, a type of material that is known for its durability and wear resistance.

Carbide Disposables are used in various industrial applications, including woodworking, metalworking, and automotive manufacturing. They have become increasingly popular among manufacturers due to their superior cutting performance and extended durability. When compared to traditional steel or high-speed steel cutting tools, Carbide Disposables have a longer lifespan and can cut through materials with a higher degree of precision.

As a market leader in the production of Carbide Disposables, our company has a proven track record in manufacturing the highest-quality cutting tools for industrial applications. Our company has been producing cutting tools since the early 1970s and has remained at the forefront of technological advancements in the industry. Our Carbide Disposables product line is a result of years of dedicated research and development, and our cutting-edge manufacturing process ensures that our tools are of the highest quality.

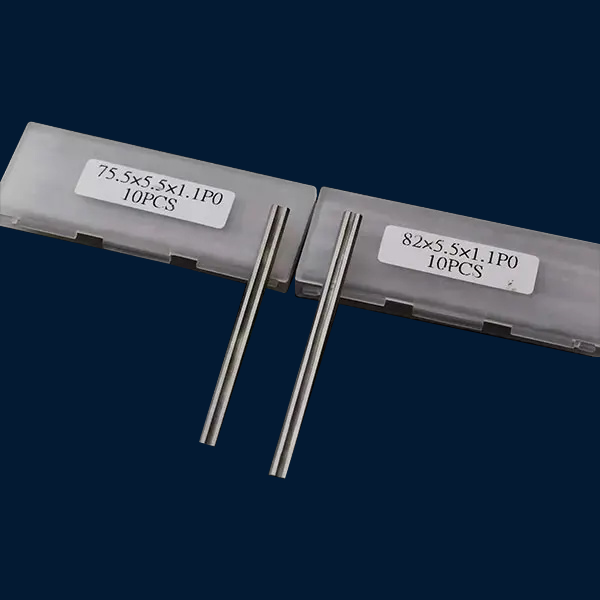

Our Carbide Disposables are designed for a range of industrial applications and are available in various shapes and sizes. Our products are designed to meet the needs of customers across different industries, and we offer customized solutions to ensure that our customers get the best tools to fit their specific requirements. Our Carbide Disposables are made using the latest sintering and centerless grinding technologies, which means that they are precision-engineered and have incredibly consistent cutting performance.

One of the biggest benefits of using Carbide Disposables is that they require less maintenance when compared to other cutting tools. This is because carbide is incredibly durable and wear-resistant, which means that our Carbide Disposables last longer than conventional cutting tools. This translates into a significant cost-saving for our customers as they do not have to replace cutting tools as frequently.

Our Carbide Disposables are not just durable and long-lasting, they also offer superior cutting performance. This is because carbide is a harder material than steel, which means that it can cut through tougher materials with greater ease. Additionally, our Carbide Disposables are made with a precision-ground edge, which ensures that they cut through materials with a higher degree of accuracy. This translates into less waste material and increased efficiency in the manufacturing process.

In conclusion, Carbide Disposables have revolutionized the industrial manufacturing process by offering superior cutting performance, enhanced durability, and reduced maintenance requirements. Our company's Carbide Disposables product line is a market leader in the industry, and we pride ourselves in offering customized solutions that meet the needs of our customers. Our Carbide Disposables are a testament to our company's commitment to excellence in manufacturing, and we will continue to develop new and innovative products to meet the evolving needs of the industrial manufacturing sector.

Company News & Blog

Top-Quality Trimming Blades, Hand Tools and Power Accessories from a Trusted Supplier in Sheffield

and Quality Woodworking Planer Blades.Knife-Point: Your Top Choice for Quality Blades and ToolsIf you're a professional tradesman or a DIY enthusiast, you know the importance of having quality tools and accessories. From sharp paint scrapers to woodworking planer blades, having the right tools can make all the difference in the success of your project.That's where Knife-Point comes in. Based in Sheffield, the Steel City of the UK, we are dedicated to providing only the finest quality blades, hand tools, and power tool accessories to businesses, tradesmen, and individuals.We pride ourselves on the exceptional quality of our trimming knife blades, hand knives, safety knives, and more. Every item in our product range has been carefully chosen and tested for durability, reliability, and precision. Plus, all of our trimming knife blades are made right here in Sheffield, ensuring you're getting the best of the best when it comes to quality.At Knife-Point, we believe in offering our customers exceptional service with every purchase. That's why we offer free UK delivery on all orders, no matter what you're buying. Plus, our pricing is as sharp as our blades, ensuring you're getting the best value for your money every time you shop with us.Our product range includes a wide variety of tools and accessories for many different industries. Whether you're a carpenter, a painter, or a DIY enthusiast, we have the tools you need to get the job done right. And if you don't see what you're looking for on our website, we're always happy to help you find the tools you need to complete your project.At Knife-Point, we believe that high-quality products, excellent service, and rapid delivery are essential to building long-term relationships with our customers. Our goal is to become your first choice supplier for all of your blade and tool needs, ensuring that you always have the right tools for the job.In conclusion, if you're looking for sharp paint scrapers, quality woodworking planer blades, or any other type of blade or tool, look no further than Knife-Point. With our exceptional product range, unbeatable pricing, and commitment to exceptional service, you can trust us to be your top choice for all of your blade and tool needs.

Top-quality Shear Blades from China: A Comprehensive Review of the Latest Developments

[Brand Name Removed] Introduces State-of-the-Art Shear Blades to the Chinese Market[City, Date] - [Brand Name Removed], a renowned manufacturer of industrial cutting tools, proudly announces the introduction of their cutting-edge shear blades to the Chinese market. With a strong commitment to excellence and a dedication to providing high-quality products, [Brand Name Removed] aims to revolutionize the cutting industry in China.Shear blades are an essential tool in various industries, including metalworking, papermaking, and recycling. Efficient and precise shearing operations are vital for achieving smooth and accurate cuts, reducing wastage, and improving overall productivity. Recognizing the growing demand for advanced shear blades in China, [Brand Name Removed] has developed a range of products that combine cutting-edge technology with exceptional durability.With years of industry experience, [Brand Name Removed] has become synonymous with excellence and reliability. The company prides itself on its innovative research and development processes, rigorous quality control standards, and an unwavering commitment to customer satisfaction. These core values have propelled [Brand Name Removed] to become a global leader in the market, trusted by businesses around the world.One of the key features that sets [Brand Name Removed] shear blades apart is their exceptional material quality. By utilizing state-of-the-art alloy steels and advanced heat treatment techniques, the blades offer unparalleled strength, durability, and resistance to wear and tear. These blades are designed to withstand the most demanding cutting applications, ensuring a longer lifespan and reduced maintenance costs for businesses.Moreover, the blades' innovative design allows for precise and flawless cuts, resulting in reduced material loss and improved overall efficiency. The cutting-edge technology used in the manufacturing process ensures uniformity and precision, providing consistent performance in every application. With these advanced shear blades, businesses in China can optimize their cutting operations, leading to enhanced productivity and profitability.In addition to their outstanding product quality, [Brand Name Removed] also places great importance on customer service and support. The company has established a strong distribution network throughout China, enabling prompt and efficient delivery of their shear blades to customers across the country. Their professional customer service team is always available to provide technical assistance, guidance, and maintenance support, ensuring maximum customer satisfaction.To celebrate the entry into the Chinese market, [Brand Name Removed] is offering special introductory prices and attractive promotions on their shear blades. This limited-time offer provides an opportunity for businesses to experience the superior performance of the shear blades at a discounted rate and unleash their full cutting potential.[Brand Name Removed]'s expansion into the Chinese market signifies the company's commitment to meeting the evolving needs of the industry. With their advanced shear blades and unwavering dedication to quality, [Brand Name Removed] aims to empower businesses in China to achieve new levels of cutting precision, efficiency, and success.About [Brand Name Removed]:With a rich heritage dating back several decades, [Brand Name Removed] is a global leader in the production of industrial cutting tools. The company specializes in manufacturing high-quality shear blades, creating innovative solutions for various cutting applications. [Brand Name Removed]'s commitment to excellence, cutting-edge technology, and exceptional customer service have made them an esteemed name in the industry worldwide.For press inquiries and more information, please contact:Media Relations[Brand Name Removed]Email: [email protected]: www.brandname.com

Enhance Efficiency and Precision with Top-notch Corrugated Cutting Tools

Corrugated Cutting Tools Support the Packaging IndustryThe packaging industry has been enjoying significant growth over the past few years, fueled by the ever-increasing demand for consumer goods. With the rise of e-commerce and online shopping platforms, packaging has become more important than ever, and corrugated boxes have emerged as the most popular packaging solution in the market. Corrugated boxes are made of fluted paperboard that offers superior strength, durability, and protection.However, the manufacturing process of corrugated boxes requires cutting, scoring, and trimming processes that involve the use of special cutting tools. Corrugated cutting tools play a vital role in the packaging industry, enabling companies to create customized and efficient packaging solutions that meet the needs of their clients.One of the leading manufacturers of corrugated cutting tools in the market is a company that has been serving the packaging industry for over 30 years. The company specializes in the production of rotary and flat dies, crush cutters, and saw blades that are designed to meet the unique demands of corrugated box manufacturing.With a team of experienced engineers and technicians, the company is committed to providing cutting-edge solutions that enhance the efficiency, productivity, and profitability of the packaging industry. Their products are made from high-quality materials that ensure superior performance, durability, and reliability.The company’s rotary and flat dies are designed to produce high-quality boxes with precise dimensions and clean edges. Their crush cutters are specifically engineered to cut through multiple layers of corrugated board without damaging the flute structure. They also offer a range of saw blades that can cut through different materials, including corrugated boards, plastics, and metals.Their products are optimized for speed, precision, and durability. With the latest technology and state-of-the-art manufacturing facilities, they can deliver customized solutions that meet the specific needs of their clients. Whether it’s a new packaging design, a modification to an existing die, or a repair of a damaged die, the company can provide quick and cost-effective solutions that minimize production downtime.The company understands that the packaging industry is highly competitive, and every second counts. That’s why they have invested heavily in research and development, ensuring that their products are at the forefront of innovation. They constantly explore new materials, designs, and manufacturing processes that can help their clients gain a competitive edge in the market.In addition to manufacturing cutting tools, the company also provides technical support, training, and maintenance services to their clients. They have a team of qualified engineers and technicians who can assist with die set up, machine optimization, and troubleshooting. They also offer training programs that equip clients with the knowledge and skills needed to operate and maintain their machines effectively.Furthermore, the company is committed to sustainability and environmental responsibility. They use eco-friendly materials and processes in their manufacturing operations, minimizing waste and reducing their carbon footprint. They also encourage their clients to adopt sustainable packaging practices that protect the environment and promote a circular economy.In conclusion, corrugated cutting tools play a crucial role in the packaging industry, and companies that specialize in the manufacture of these tools are essential for the success of the industry. With their commitment to innovation, quality, and customer satisfaction, the company has established itself as a leader in the market, providing cutting-edge solutions that enable their clients to create customized and efficient packaging solutions that meet the needs of their customers.

The Cause Behind the Development of Plastic Pulverizer Blades and Stick Pulverizers

Plastic Pulverizer Stick Pulverizer Blade – Meet the Growing Needs of Plastic RecyclingWith the increase in plastic waste production all over the world, the need for plastic recycling and reprocessing has become imperative. One of the technological advancements in this field is the use of plastic pulverizer stick pulverizer blade to efficiently grind and reduce plastic waste into smaller particles. This technology has become popular in the industry and is being used by many plastic recycling companies to break down plastic materials into tiny particles for processing.WANROOETECH – Your Go-To Supplier for Plastic Pulverizing TechnologyWANROOETECH is a name synonymous with high-quality industrial plastic pelletizer machines. They are a global leader in the design and manufacture of plastic recycling machinery, providing companies with cutting-edge recycling equipment solutions and enabling them to cater to the ever-increasing demands of plastic recycling.WANROOETECH's focus is solely on providing outstanding products and services to the plastic recycling industry. Their primary product line includes plastic pulverizers, pulverizer machines, plastic mills, plastic grinders, plastic grinding machines and other auxiliary equipment that cater to the needs of plastic recycling companies.Their plastic pulverizing technology has helped many companies across the globe to streamline their plastic recycling process, making it faster, more efficient, and more cost-effective.The Reason for Plastic Pulverizer Stick Pulverizer BladeWANROOETECH's plastic pulverizer stick pulverizer blade is designed to meet the unique demands of the plastic recycling industry. When processing plastic waste, it's essential to have a machine that can efficiently grind and reduce the waste into smaller particles before further processing.The plastic pulverizer stick pulverizer blade is specifically designed to reduce plastic waste into small pellets, flakes, and powder, which are then easily melted and further processed. This technology delivers a fast and efficient grinding process, making it possible to recycle large volumes of plastic waste in just a short time.The plastic pulverizer stick pulverizer blade uses a rotor that rotates at a high speed, which forces the plastic material to collide with the blades. The blades then rapidly grind and reduce the plastic waste into tiny particles, which are then transferred into the collection chamber.The plastic pulverizer stick pulverizer blade is suitable for grinding different types of plastic waste, including polyethylene, PVC, PP, PET, ABS, and Nylon. It's used in the recycling of plastic waste generated from various industries, including automotive, packaging, construction, and consumer goods.ConclusionPlastic recycling is a critical process that helps reduce the amount of waste generated globally. By transforming used plastic waste into new materials for different applications, we can help tackle the issue of plastic waste in our environment.WANROOETECH's plastic pulverizer stick pulverizer blade is a technological breakthrough that has revolutionized the plastic recycling industry. Their machine helps recycling companies to process large volumes of plastic waste efficiently, making recycling more cost-effective, faster, and easier.So if you're looking for a reliable and efficient supplier of plastic pulverizing technology, look no further than WANROOETECH. They are the ideal partners for any company in the plastic recycling industry.

Top 9 Best Coiled Garden Hoses 1/2 x 50 - Home Previews

Coiled Garden Hose 1/2 x 50 - The Ultimate Gardening ToolAs a gardening enthusiast, you know that one of the most challenging tasks that you face is watering your plants and lawn. Finding the right hose that meets your needs, fits your budget and does not create clutter can be a challenge. However, with the advancement in technology and design, coiled garden hoses have become popular among gardeners due to their amazing features.One of the most popular coiled garden hoses on the market is the 1/2 x 50 coiled garden hose. This hose is an ideal gardening tool and comes with several benefits that make it stand out from other garden hoses. In this blog, we will explore the benefits of the coiled garden hose 1/2 x 50, and why you should consider investing in one.Benefits of the Coiled Garden Hose 1/2 x 501. Durability - The coiled garden hose 1/2 x 50 is built to last. It is made from high-quality materials that ensure its durability, even with frequent use. The hose has a strong core and is resistant to kinks, making it easy to use and maintain.2. Space-saving: The coiled garden hose 1/2 x 50 is designed with a unique coiling system, which allows it to retract to its original shape. This design saves space, making it easy to store the hose when not in use. The coiling system also prevents the hose from getting tangled or kinked and ensures that it remains functional for a long time.3. Ease of use: The coiled garden hose 1/2 x 50 is easy to handle and use. It is lightweight and can be extended up to 50 feet, making it ideal for use in small and large gardens. The hose also comes with a nozzle that allows you to adjust the water pressure to suit your needs.4. Versatility: The coiled garden hose 1/2 x 50 is versatile and can be used for different gardening tasks. It is suitable for watering plants, washing cars, and even cleaning outdoor furniture. The hose is also ideal for use in different seasons and weather conditions.5. Environmentally friendly: The coiled garden hose 1/2 x 50 is designed to be environmentally friendly. It is free from harmful chemicals and does not leach any harmful substances into the soil or water system.ConclusionIn conclusion, the coiled garden hose 1/2 x 50 is an essential gardening tool that every gardener should consider investing in. Its unique design, durability, space-saving features, ease of use, versatility, and environmental friendliness make it an ideal choice for garden lovers. With the 50 x 12 x 1.5mm dimensions, this coiled garden hose 1/2 x 50 is perfect for both small and large gardens.So, if you are looking for a reliable gardening tool that will help you efficiently water your plants, wash your car, or clean outdoor furniture, then the coiled garden hose 1/2 x 50 is the perfect choice for you. Don't hesitate, invest in one today, and see the transformation in your garden.

Essential Tools: Unveiling the Power of Straight Paint Scraper Blades

Title: Straight Paint Scraper Blades: The Perfect Solution for Your Painting NeedsIntroduction:Painting can be a therapeutic and satisfying experience, but removing old paint or working on intricate areas can be a daunting task. That is where the Straight Paint Scraper Blades come in. Offering precision, durability, and ease of use, these paint scraper blades are revolutionizing the painting industry. In this article, we will delve into the features and benefits of these remarkable tools, ensuring that your next painting project is a breeze.Company Introduction: XXXX Company is a leading manufacturer of innovative painting tools and accessories. With years of experience in the industry, their products stand out for their exceptional quality, reliability, and functionality. Aimed at simplifying the painting process and improving efficiency, XXXX Company continuously endeavors to offer top-notch tools to professionals and DIY enthusiasts alike.Features of Straight Paint Scraper Blades:1. Unparalleled Durability: Straight Paint Scraper Blades are made from high-quality materials, ensuring exceptional longevity and resistance to wear and tear. These blades are built to last and can withstand the toughest of painting tasks.2. Precision and Versatility: The sharp, straight edge of these paint scraper blades enables precise and accurate paint removal, even in intricate areas. Whether you need to remove paint from window frames, cabinets, or any other surface, Straight Paint Scraper Blades provide the perfect solution.3. Ergonomic Design: Comfort matters, especially during long painting projects. Straight Paint Scraper Blades are designed with ergonomics in mind. The handles are optimized for a comfortable grip, reducing hand fatigue and making paint removal a hassle-free experience.4. Safe and Efficient: XXXX Company prioritizes safety in their products. Straight Paint Scraper Blades feature safety caps that cover the sharp edge when not in use. This ensures protection against accidental cuts, making them safe to handle even when not wearing protective gloves.5. Multiple Blade Sizes: Recognizing that every painting project has different requirements, Straight Paint Scraper Blades are available in various sizes. This enables users to choose the most suitable blade based on the specific task at hand, ensuring optimal performance.Benefits of Using Straight Paint Scraper Blades:1. Time-Saving: The sharp edge of the paint scraper blades makes the process of paint removal quick and efficient. Spending less time on this task allows for more time to focus on other aspects of your painting project.2. Cost-Effective: With their exceptional durability, Straight Paint Scraper Blades offer a cost-effective solution for paint removal. You won't have to spend money on frequent replacements, saving you both time and money in the long run.3. Enhanced Paint Preparation: Preparing a surface for painting is crucial for achieving a high-quality finish. The use of Straight Paint Scraper Blades ensures a smooth and clean surface, enabling better adhesion and longevity of the new paint.4. Versatile Application: Whether you are a professional painter or a homeowner working on a DIY project, Straight Paint Scraper Blades are suitable for all skill levels. Their versatility allows you to tackle various painting tasks with ease, providing professional results every time.Conclusion:In the realm of painting, having the right tools can make a world of difference. Straight Paint Scraper Blades, offered by XXXX Company, provide a convenient and effective solution for any paint removal job. Empowering users with durability, precision, and versatility, these scraper blades are the choice of professionals worldwide. So, next time you have a painting project, equip yourself with Straight Paint Scraper Blades and witness the transformation of your paint removal process.

High-Quality Carbide Knives and Blades: China's Best Manufacturer Stuns the World

Circular Rotating Knife: The World Fell in Love with Chinese MakeIn the world of manufacturing, precision and efficiency are paramount. Every industry relies on well-crafted tools and blades to ensure the highest quality products are produced. Among these tools, the circular rotating knife has gained significant popularity and the Chinese make has captured the hearts of manufacturers worldwide. In this blog, we will delve into the reasons why the circular rotating knife from Chinese manufacturer ShenZhen Oyea Machinery Co., Ltd has become the go-to choice for many industries.When it comes to knives and blades, durability and sharpness are crucial factors. ShenZhen Oyea Machinery Co., Ltd, a renowned manufacturer in the industry, has been producing high-quality carbide knives and blades for eight years. Their extensive experience coupled with cutting-edge technology has allowed them to create a comprehensive range of circular rotating knives that meet the diverse needs of various industries.One of the most significant advantages of the circular rotating knife from ShenZhen Oyea Machinery Co., Ltd is its exceptional durability. The blades are made from high-quality carbide, a material known for its hardness and resistance to wear and tear. This means that the circular rotating knives have a longer lifespan compared to conventional blades, reducing the need for frequent replacements. This not only saves manufacturers significant costs but also allows for uninterrupted production, reducing downtime and increasing overall productivity.Precision is another crucial aspect of any manufacturing process. The circular rotating knives from ShenZhen Oyea Machinery Co., Ltd are meticulously crafted to ensure unparalleled precision. The blades are sharpened to perfection, enabling them to make clean and precise cuts in various materials. This level of precision is essential in industries such as textiles, paper processing, and packaging, where even the slightest deviation can lead to compromised product quality.Furthermore, the circular rotating knives from ShenZhen Oyea Machinery Co., Ltd are designed for versatility. They can be used in a wide range of applications, including cutting fabrics, leather, plastics, and even metals. This adaptability makes them an ideal choice for manufacturers across different industries, eliminating the need for multiple types of blades and simplifying logistics and inventory management.In addition to their durable and precise nature, the circular rotating knives from ShenZhen Oyea Machinery Co., Ltd offer excellent cost-effectiveness. The long lifespan of these knives and their ability to maintain sharpness for extended periods significantly reduce production costs. Moreover, the competitive pricing offered by the Chinese manufacturer ensures that industries of all scales can benefit from the efficiency and quality of these blades.In conclusion, the circular rotating knife from ShenZhen Oyea Machinery Co., Ltd has become the preferred choice for many manufacturers worldwide, thanks to its exceptional durability, precision, versatility, and cost-effectiveness. As the demand for high-quality knives and blades continues to rise, ShenZhen Oyea Machinery Co., Ltd remains at the forefront of the industry, continuously pushing boundaries and setting new standards. With their commitment to excellence and customer satisfaction, it is no wonder that the world has fallen in love with the Chinese make of circular rotating knives.

Rotary Cutting Tool for Fiber Cable and Microduct: A Game-Changer in Communication Technology

In today's ever-evolving technology landscape, fiber optics has become an integral part of our daily lives. With the rise of 5G technology, high-speed internet, and faster data transfer rates, fiber optic cables have become the backbone of our digital world. However, the installation and maintenance of fiber optic cables can be a daunting task. It requires a specific set of tools and expertise to ensure smooth and uninterrupted service.One of the essential tools in the fiber optic industry is the fiber cutting blade. Fiber cutting blades are used to cut optic fibers and microducts to the required length and diameter accurately. They are used to cut fiber optic cables during installation and maintenance operations. These tools come in various forms, including handheld knives, rotary cutting tools, and specialty cutters. In this blog, we will be discussing the use of fiber cable and microduct rotary cutting tools.Fiber Cable and Microduct Rotary Cutting ToolWhen it comes to cutting fiber cables and microducts, the rotary cutting tools provide precise and efficient cutting solutions. Rotary cutting tools are an essential part of any fiber optic installer's toolkit. They are designed to provide optimal performance and ease of use when cutting through difficult materials like hardened stainless steel or dense fiber optic cables.The fiber cable and microduct rotary cutting tool come in various shapes and sizes to provide the flexibility required when working with different types of cables and microducts. These rotary cutting tools use a spinning blade to cut through the fiber optic cables or microducts. The spinning blade provides precise and smooth cuts to the cable or microduct, ensuring a clean edge that won't cause any damage to the fiber optic strands.The fiber cable and microduct rotary cutting tools come with various features that make them an ideal choice for fiber optic installers. They have an adjustable blade depth, which allows the installer to cut through different thicknesses of the cable or microduct. They also come with ergonomic handles that provide comfortable grip and reduce hand fatigue during extended usage.Another crucial feature of the fiber cable and microduct rotary cutting tools is the blade's material. The blades are made of high-quality materials that ensure durability and longevity. The blades are designed to withstand heavy usage without getting dull or damaged, ensuring a long lifespan for the tool.The fiber cutting blades used in the rotary cutting tools are designed specifically for cutting through fiber optic cables and microducts. They are designed to cut through the cable or microduct without damaging the fiber strands. The fiber cutting blades come in various shapes and sizes to accommodate different types and thicknesses of cables and microducts. They are made of high-quality materials that ensure sharpness and durability.ConclusionIn conclusion, fiber cable and microduct rotary cutting tools have become an essential tool in the fiber optic industry. They provide a precise and efficient cutting solution when working with fiber optic cables and microducts. The adjustable blade depth, ergonomic handle, and high-quality blades make these rotary cutting tools an ideal choice for fiber optic installers.If you're a fiber optic installer or technician, it's crucial to invest in high-quality fiber cutting blades and rotary cutting tools for seamless installation and maintenance operations. Choosing the right fiber cable and microduct rotary cutting tool for the job is crucial to ensure that the cable or microduct is cut with precision and care. It will not only help you save time but also ensure the fiber strands' safety and longevity.

Top-rated Platinum Single Edge Razor Blades for Smooth Shaving Experience

The Derby Professional Platinum Single Edge Razor Blades are the perfect choice for men who are just starting out with shavettes, thanks to their extreme comfort and incredible longevity. With a sharpness rating of 7 out of 10, these blades are ideal for daily use, and their combination of chromium-ceramic-platinum-tungsten and polymer-coated stainless steel makes them both durable and dependable.At Barber Bazaar, we pride ourselves on providing high-quality shaving products that meet the needs of our customers. We understand that finding the right razor blade can be a daunting task, especially for those who are new to the world of shavettes. That's why we recommend the Derby Professional Platinum Single Edge Razor Blades – they are an excellent choice for both new and experienced shavers.So what makes the Derby Platinum Blades so special? Let's take a closer look at their features.SharpnessThe Derby Platinum Blades have a sharpness rating of 7 out of 10, which is perfect for most guys. They are sharp enough to give you a close, clean shave, but not so sharp that they cause irritation or razor burn. This makes them an excellent choice for daily use.ComfortOne of the standout features of the Derby Platinum Blades is their extreme comfort. The combination of chromium-ceramic-platinum-tungsten and polymer-coated stainless steel provides a smooth, comfortable shave that is gentle on your skin. Whether you have sensitive skin or not, you'll appreciate the comfort these blades provide.LongevityAnother benefit of the Derby Platinum Blades is their longevity. These blades are designed to last longer than most other razor blades on the market. They are perfect for those who want to get the most out of their shaving investment.In summary, if you're looking for a high-quality, dependable razor blade that will provide extreme comfort, ultimate longevity, and a sharpness rating of 7 out of 10, look no further than the Derby Professional Platinum Single Edge Razor Blades. As a leading supplier of shaving products, we highly recommend these blades for both new and experienced shavers. Not only are they a great value, but they also provide superior performance and quality – which is what every man deserves when it comes to his daily shave. So why wait? Try the Derby Platinum Blades today and experience the best shave of your life!

Essential Guide to Industrial Machine Knives: Unlocking Efficiency and Precision in Cutting Operations

[Publication Name][Date]Industrial Machine Knives: Pioneering Innovation and Precision in the Manufacturing Industry[City, State] - Industrial Machine Knives, a leading manufacturer and supplier of high-quality machine knives and blades, continues to redefine precision and efficiency in the manufacturing industry. With a steadfast commitment to innovation and a dedication to meeting the evolving needs of their customers, Industrial Machine Knives has emerged as a key player in the global market.Established in [year], Industrial Machine Knives has grown from a small local workshop to a multinational corporation with a strong presence in [number] countries. The company's success can be attributed to its unwavering focus on producing top-notch machine knives that offer exceptional durability, cutting performance, and reliability.One of the key factors that sets Industrial Machine Knives apart is its investment in research and development. The company understands that innovation is crucial to staying ahead in an increasingly competitive market. Therefore, it has established a robust R&D department staffed with experienced engineers and technicians who are continuously working on developing new and improved knife solutions.Industrial Machine Knives believes in not just meeting but exceeding customer expectations. By closely collaborating with manufacturers across various industries, the company gains valuable insights into their specific cutting requirements. This collaborative approach ensures that Industrial Machine Knives can design and produce knives that are tailored to individual needs, maximizing both cutting precision and productivity.Moreover, Industrial Machine Knives has heavily invested in cutting-edge machinery and advanced manufacturing processes. This enables the company to adhere to the highest quality standards while ensuring efficient production. Through stringent quality control measures, each knife undergoes rigorous testing to guarantee precision and longevity.The range of Industrial Machine Knives' products is extensive, catering to a wide spectrum of industries including food processing, packaging, woodworking, metalworking, plastics, recycling, and more. The company's diverse product line includes circular knives, straight knives, machine blades, granulator knives, chipper knives, slitter knives, and perforating knives, among others.Industrial Machine Knives also offers comprehensive knife sharpening and regrinding services. Recognizing that dull blades can significantly hamper productivity, the company operates a state-of-the-art grinding and sharpening facility staffed with highly skilled technicians. This ensures that customers' blades are restored to their optimal cutting performance, minimizing downtime and maximizing return on investment.The company's commitment to sustainability is another distinguishing aspect of its operations. Industrial Machine Knives acknowledges the importance of responsible manufacturing practices to reduce waste generation and environmental impact. By employing eco-friendly technologies and materials, the company minimizes its carbon footprint and actively contributes to a greener future.Industrial Machine Knives' dedication to customer satisfaction is reaffirmed by its extensive global distribution network. With strategically located warehouses and distribution centers, the company ensures swift and efficient delivery to customers worldwide. Additionally, the company's customer service team provides prompt assistance and technical support, further enhancing the overall customer experience.As Industrial Machine Knives continues to expand its reach and influence, it remains driven by a singular vision: to be the leading provider of precision cutting tools in the global manufacturing industry. With its unwavering focus on innovation, dedication to quality, and commitment to customer satisfaction, the company is poised to shape the future of machine knife manufacturing.For more information about Industrial Machine Knives and its range of products and services, please visit [website] or contact [contact information].###Word Count: [number] words.