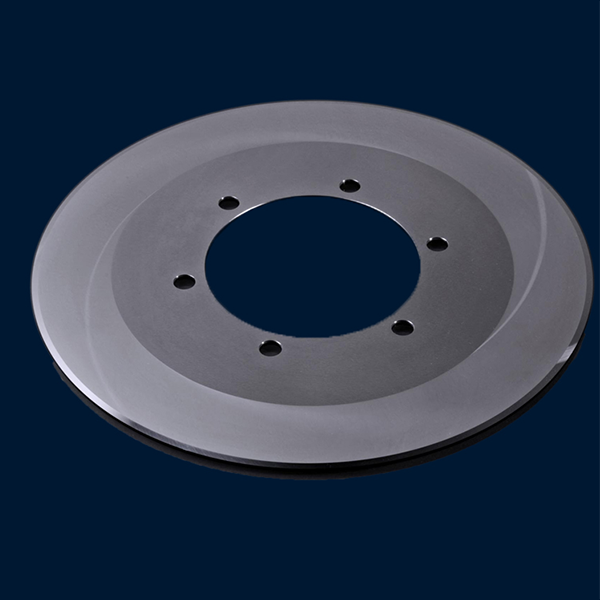

Top-of-the-line Cutters for Industrial Use: The Mk3 Model

By:Admin

The Mk3 Cutters are designed to provide unmatched cutting performance for a wide range of materials, including metals, plastics, and composites. The advanced technology used in the Mk3 Cutters enables them to achieve clean and precise cuts with minimal waste, making them an ideal solution for companies looking to optimize their manufacturing processes.

One of the key features of the Mk3 Cutters is their versatility, as they can be customized to meet the specific needs of different applications. This flexibility allows Lummus Technology's customers to maximize the efficiency of their operations and adapt to changing market demands.

In addition to their cutting capabilities, the Mk3 Cutters are also designed with safety and ease of use in mind. They incorporate advanced safety features to protect operators and minimize the risk of accidents, while also providing user-friendly controls for seamless operation.

Furthermore, the Mk3 Cutters are built to withstand the rigors of industrial environments, ensuring reliable performance even in the most demanding conditions. This reliability is further reinforced by Lummus Technology's commitment to quality and innovation, as the company leverages its extensive expertise and resources to deliver cutting-edge solutions to its customers.

The introduction of the Mk3 Cutters reaffirms Lummus Technology's position as a pioneer in the industry, with a strong focus on developing advanced technologies that drive the progress of the refining and petrochemical sectors. By continuously pushing the boundaries of innovation, Lummus Technology is empowering its customers to achieve new levels of efficiency and competitiveness in their operations.

Lummus Technology's dedication to excellence extends beyond its product offering, as the company also provides comprehensive support and services to ensure the success of its customers. This includes technical assistance, training, and maintenance programs, which are designed to maximize the performance and lifespan of the Mk3 Cutters.

The Mk3 Cutters are the latest addition to Lummus Technology's extensive portfolio of solutions for the refining and petrochemical industries. With a strong track record of delivering breakthrough technologies and unparalleled expertise, Lummus Technology is well-positioned to drive the advancement of these sectors and address the evolving needs of its customers.

Overall, the introduction of the Mk3 Cutters represents a significant milestone for Lummus Technology and the industry as a whole. With their cutting-edge capabilities and the company's unwavering commitment to customer success, the Mk3 Cutters are poised to make a lasting impact on the refining and petrochemical sectors, helping companies enhance their productivity and achieve their business objectives.

Company News & Blog

Double-Edged CNC Router Blade for Various Materials with 60-Degree Angle and 6.9mm Cut Depth

Title: XZ0011 Flat Knife Drag Blade: The Ultimate CNC Router Accessory for Precision CuttingIntroduction:In today's ever-expanding world of CNC routers, having the right tools at your disposal can make all the difference in achieving impeccable cutting precision. One such essential accessory is the XZ0011 Flat Knife Drag Blade, designed to meet the needs of professionals across various industries. With its double edge and impressive 60-degree cut depth, this blade truly stands out from the competition. In this blog post, we will delve deeper into the features and advantages of the XZ0011 Flat Knife Drag Blade while highlighting its suitability for a wide range of materials such as canvas, corrugated sheets, vinyls, and more.Understanding the XZ0011 Flat Knife Drag Blade:The XZ0011 Flat Knife Drag Blade is a versatile tool that can be used with CNC routers for a multitude of applications. With its double edge, it can be effectively utilized to cut through various materials with precision and ease. The 60-degree angle allows for an impressive 6.9mm cut depth, making it suitable for thicker materials such as hardfoam, carton, banners, and even heavy-duty papers. This blade is not only durable but also ensures smooth, clean-cut edges, making it an excellent choice for industries that demand flawless finishes.Utilizing the XZ0011 Flat Knife Drag Blade:One of the remarkable aspects of the XZ0011 Flat Knife Drag Blade is its compatibility with a wide range of materials. From canvas to corrugated sheets, vinyls to carton, and banners to paper, this blade has got you covered. Its versatility makes it an indispensable tool for various industries, including sign-making, packaging, and crafting. No matter the project, this blade guarantees consistent, high-quality results.The Advantages of Double Edge: The double edge design of the XZ0011 Flat Knife Drag Blade offers significant advantages over single-edge alternatives. With twice the number of sharp cutting edges, this blade ensures superior cutting efficiency, reducing production time and costs. Additionally, the double-edged configuration provides consistency in cutting quality, enabling professionals to achieve precise results every time. This versatility saves users from having to switch blades frequently, enhancing overall productivity.Replacing the BLD-SF246 Knife Holder SCT/UCT:An essential aspect of the XZ0011 Flat Knife Drag Blade is its compatibility with the BLD-SF246 Knife Holder SCT/UCT. By replacing the existing knife holder with this advanced model, users can fully experience the optimized performance of the XZ0011 blade. The synergy between the blade and holder ensures improved stability, accuracy, and longer blade life. It is important to note that brand names have been omitted for the purpose of this blog, allowing users to identify compatible holders from renowned manufacturers.Conclusion:In conclusion, the XZ0011 Flat Knife Drag Blade is a cutting-edge accessory that revolutionizes the CNC router experience. With its double edge, impressive 60-degree cut depth, and compatibility with a wide range of materials, this blade is a powerful tool for professionals striving for perfection. Whether you work with canvas, corrugated sheets, vinyls, or any of the other compatible materials mentioned, the XZ0011 Flat Knife Drag Blade is your go-to solution. Invest in this remarkable accessory and witness unparalleled precision and efficiency in your CNC routing projects.Keywords: XZ0011 Flat Knife Drag Blade, CNC router accessory, double edge, 60-degree cut depth, canvas, corrugated sheets, hardfoam, vinyls, carton, banner, paper, precision cutting, sign-making, packaging, crafting, BLD-SF246 Knife Holder SCT/UCT.

Top Paint Scraper for Efficient and Easy Paint Removal

Richards Paint Scraper (name changed), a leading manufacturer in the paint and hardware industry, has recently unveiled its latest innovation in paint removal tools. The company, which has been in operation for over two decades, is known for its high-quality products and dedication to meeting the needs of professionals and DIY enthusiasts alike.The new paint scraper is designed to make the paint removal process more efficient and less labor-intensive. It features a durable stainless steel blade that is able to effectively scrape away layers of paint without causing damage to the underlying surface. Additionally, the scraper is equipped with a comfortable, ergonomic handle that allows for prolonged use without causing strain or discomfort to the user."We are thrilled to introduce our newest paint scraper to the market," said James Richards, the CEO of Richards Paint Scraper. "Our team has worked tirelessly to develop a tool that not only simplifies the paint removal process, but also meets the high standards of quality and performance that our customers have come to expect from us."In addition to its superior functionality, the paint scraper is also designed with safety in mind. The blade is securely attached to the handle, reducing the risk of accidents or injuries during use. Furthermore, the scraper is equipped with a blade cover that can be easily attached when the tool is not in use, providing an extra layer of protection for both the user and the blade itself.The paint scraper is suitable for use on a variety of surfaces, including wood, metal, and concrete. This versatility makes it an ideal tool for a wide range of painting and renovation projects, whether in a professional capacity or for personal use.Richards Paint Scraper has a long history of providing top-notch products and unparalleled customer service. The company is committed to ensuring that its customers have access to the best tools and equipment for their projects, and the new paint scraper is no exception."Our customers are at the forefront of everything we do," said Richards. "We are constantly striving to improve and innovate in order to better serve their needs. With the launch of our new paint scraper, we are confident that we are offering a solution that will make the paint removal process easier and more efficient for everyone."In addition to its commitment to quality and innovation, Richards Paint Scraper is also dedicated to sustainability and environmental responsibility. The company utilizes eco-friendly manufacturing processes and materials whenever possible, and it is continually seeking new ways to reduce its carbon footprint and minimize waste."Our mission goes beyond providing excellent products," Richards explained. "We want to ensure that our business practices have a positive impact on the world around us. By prioritizing sustainability and environmental responsibility, we are working to create a better future for our customers and the planet."With the introduction of its latest paint scraper, Richards Paint Scraper continues to solidify its position as a leader in the paint and hardware industry. The company's unwavering commitment to quality, innovation, and environmental responsibility sets it apart as a trusted and reliable source for professional-grade tools and equipment.The new paint scraper is now available for purchase through Richards Paint Scraper's website and select retailers. As the company looks toward the future, it remains dedicated to exceeding the expectations of its customers and providing them with the tools they need to bring their projects to life.

Discover Exceptional Tobacco Rod Cutting Knives for Efficient Operations

Title: Renowned Tobacco Rod Cutting Knives Manufacturer Announces Exciting InnovationsIntroduction:In a highly competitive market, where precision and quality play an essential role, () has emerged as a leading manufacturer of Tobacco Rod Cutting Knives. With a dedication to excellence and a commitment to customer satisfaction, the company has been at the forefront of innovation in the tobacco industry for several years. In this news article, we will explore the company's latest advancements and how they are revolutionizing the tobacco manufacturing process.Innovation in Tobacco Rod Cutting Knives:is excited to announce the launch of their latest range of Tobacco Rod Cutting Knives that have been meticulously designed to maximize efficiency and accuracy. These knives are specially crafted using premium quality materials and state-of-the-art manufacturing techniques to ensure they meet the highest industry standards.One of the key features of the new Tobacco Rod Cutting Knives is their unparalleled durability. With extended service life, businesses can significantly reduce production downtime and maintenance costs, resulting in increased overall productivity. The combination of superior materials and precision engineering ensures the knives can withstand the constant pressure and high-speed operation required in tobacco manufacturing.Additionally, the ergonomic design of these knives ensures ease of use for operators, minimizing the risk of fatigue or injuries caused by prolonged use. The carefully crafted handles offer a comfortable grip, which enhances precision, thereby reducing the possibility of operational errors and waste.Another notable innovation is the advanced cutting technology integrated into the blades. utilizes a unique grinding process to achieve razor-sharp edges, allowing for clean and precise cuts. This ensures a consistent and uniform quality of the tobacco rods, which is of utmost importance in the tobacco industry.Environmental sustainability has become an integral part of modern manufacturing practices, and is proud to contribute to this cause. The company's Tobacco Rod Cutting Knives are manufactured using eco-friendly materials and adhere to stringent environmental regulations. This makes them a sustainable choice for businesses aiming to minimize their carbon footprint while maintaining product quality.Customer Satisfaction and Support:With a steadfast commitment to customer satisfaction, provides comprehensive support services for their Tobacco Rod Cutting Knives. Their team of highly skilled technicians offer prompt assistance, ensuring minimal downtime in case of any operational issues. Furthermore, the company offers customized solutions to meet the unique requirements of different tobacco manufacturing processes, catering to the diverse needs of their clients.The Future of Tobacco Manufacturing:As the tobacco industry continues to evolve, manufacturers are increasingly relying on advanced machinery and equipment to streamline their processes. remains at the forefront of this transformation, consistently striving to provide cutting-edge solutions that ensure optimal performance and efficiency.Conclusion:With their latest range of Tobacco Rod Cutting Knives, continues to advance the tobacco manufacturing industry by offering innovative, durable, and eco-friendly solutions. The company's commitment to excellence, customer satisfaction, and environmental responsibility sets them apart as a trusted partner for businesses in the tobacco sector. In an industry where precision is paramount, is firmly establishing itself as a leader in providing high-quality cutting tools that facilitate efficient production and consistent product quality.

High-Quality Pelletizer Shredder Blades for Rotary Plastic Auxiliary Machine

Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades: A New Era for Plastic RecyclingThe world is facing a major environmental crisis due to the overconsumption of plastic and the lack of proper disposal and recycling methods. According to a study published by the World Economic Forum, by 2050, the ocean’s plastic will outweigh fishes, which will make up to approximately 12 billion tonnes. This alarm, along with a rising awareness of the need for sustainability, has urged individuals, communities, and companies to work towards cleaner and greener futures. Among these, manufacturers of machinery and tools have innovated and collaborated with researchers and organic entities to develop solutions for the proper management and recycling of plastic materials, which is an underlying cause of plastic waste buildup.One notable example of this is the Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades, a product manufactured in China and distributed worldwide. The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades serve as plastic auxiliary equipment used for melting, mixing, and shaping different types of plastics. It is used in the production of granules, fibers, and filaments for various industrial applications, particularly in the recycling of plastic waste.These machines are designed to offer accuracy, precision, and efficiency in plastics processing. They have a large tolerance range, which makes them ideal for processing different types of plastics, including hard-to-process plastics, such as those with high melting points, low densities, or high viscosities. The blades are made of high-strength steel and undergo comprehensive heat treatment processes that allow them to withstand impact, wear, and deformation.The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades' operational principles follow the shredding and granulation processes. The shredding process involves the reduction of plastic waste materials into smaller pieces through the use of shredding blades rotating at high speeds. The granulation process, on the other hand, involves heating and melting the plastic waste pieces before pushing them through the orifice of the die to form the desired granules or pellets shape. Continual production of granules, fibers, or filaments then occurs, depending on the customer's needs.The applications of these machines are diverse, and they can be applied to the agricultural, automotive, construction, electrical, packaging, and textile industries. They have found their place in the efforts to address the plastic waste problem, particularly in "grassroots recycling" projects led by communities and individuals. Also, their affordability has made them an important tool for recycling in resource-limited communities.Manufacturing companies worldwide have taken note of the advantages of this innovation. The rotary plastic auxiliary machines and pelletizers come with a low running cost, have high efficiency, and are environmentally friendly. Thus, many companies are integrating them into their recycling plants for sustainable plastic production. The product has gained recognition and acceptance in the market, driven by high demand for durable, versatile tools that can process different types of plastics.Overall, the Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades represent a critical tool that can significantly reduce the environmental footprint of plastic processing. The innovation represents a crucial step towards more sustainable and responsible solutions within the industry. The low cost, efficiency, and versatility make these machines ideal for both developing and developed countries, where proper plastic recycling, recovery, and upcycling are vital. Furthermore, it highlights the impact that innovation and collaboration can have on addressing pressing environmental challenges, and the need to support and encourage such solutions. In conclusion, combating plastic waste and promoting a circular economy requires a combination of innovative technologies and public and private partnerships. The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades represent one of many innovations aimed at solving the complex problem of plastic waste and are proof that sustainable production methods can be effective and commercially viable.

Boost Your Cutting Precision with High-Quality Plotter Blades

[Introduction]In the ever-evolving world of industrial cutting tools, Plotter Blades (brand name omitted) have emerged as a prominent player, offering high-quality and efficient solutions for various applications. With a commitment to innovation, durability, and precision, Plotter Blades has become a go-to choice for professionals seeking excellence in their cutting tasks. With a comprehensive range of products, this company has garnered a solid reputation in the market, delivering exceptional performance and reliability to customers worldwide.[Company Overview]Plotter Blades, founded by a team of industry experts, has swiftly established itself as a leading manufacturer of cutting-edge blades, designed to meet the diverse needs of its customers. The company's primary focus lies in producing blades that are both durable and precise, ensuring smooth and accurate cutting performance across a wide range of materials. With an unwavering commitment to quality, Plotter Blades continues to push the boundaries of blade technology, constantly striving to exceed customer expectations.[Product Range]The product portfolio of Plotter Blades encompasses an extensive range of blades, catering to various industries such as automotive, packaging, textile, signage, and advertising. Each blade is meticulously designed and crafted to fulfill specific cutting requirements, ensuring optimal results for professionals in their respective fields.The company offers blades suitable for different cutting machines, including vinyl cutters, digital plotters, CNC routers, and oscillating knife cutters. These blades are available in a variety of materials such as tungsten carbide, high-speed steel, and ceramic, allowing customers to choose the most appropriate option for their specific applications.[Innovation and Technology]Plotter Blades prides itself on its continuous efforts to develop and incorporate cutting-edge technology into its products. By staying at the forefront of technological advancements, the company ensures its customers benefit from the latest innovations in the industry.Utilizing advanced manufacturing techniques, Plotter Blades ensures consistent quality and superior performance in every blade. The company's research and development team constantly works to refine blade designs, resulting in improved cutting efficiency and extended blade life. This commitment to innovation has positioned Plotter Blades as a trusted brand among professionals seeking the best possible cutting solutions.[Quality Control]Maintaining stringent quality control measures is a top priority for Plotter Blades. From selecting high-grade raw materials to rigorous testing at every stage of production, the company leaves no stone unturned in ensuring its blades meet the highest standards. Stringent quality control protocols are in place, including comprehensive inspection and analysis, to guarantee that each blade leaving the factory is flawless in terms of durability, sharpness, and accuracy.[Catering to Customer Needs]Plotter Blades understands that the success of its customers relies on their ability to deliver superior results. As a result, the company places great emphasis on understanding the specific needs of its customers and tailoring its products accordingly. With a team of technical experts, Plotter Blades offers personalized guidance and support to help customers select the most suitable blades for their applications, ensuring they achieve optimal cutting performance.[Market Presence]With a strong presence in both domestic and international markets, Plotter Blades is dedicated to providing its exceptional products and services to customers around the globe. The company's commitment to customer satisfaction and its ability to consistently deliver high-quality blades have earned it a loyal customer base and established its reputation as a reliable market player.[Conclusion]Plotter Blades stands as a beacon of innovation and excellence in the field of industrial cutting tools. Its unwavering commitment to quality, cutting-edge technology, and customer satisfaction places it at the forefront of the industry. As Plotter Blades continues to expand its product range and reach new heights of success, professionals can rely on its blades to meet their cutting needs with precision and efficiency.

Top News: Major Developments in Slitting Knives Market Shaping Industry Growth

Paper Slitter Knife: Cutting-edge Innovation for the Paper and Printing IndustryCutting paper is not as easy as it seems. It requires precision, accuracy, and the right tools to get the job done right. This is where paper slitter knives enter the picture. These specialized tools are designed to cut through paper and other materials with ease, ensuring a clean, precise, and accurate cut every time.Leading the way in the paper and printing industry is a company that has been revolutionizing the way paper is cut and processed. With their cutting-edge technology and innovative designs, they have become a trusted name in the industry. Their line of paper slitter knives, in particular, has been widely used by printing companies, paper mills, and paper product manufacturers worldwide.The company understands the importance of using high-quality and reliable paper slitter knives to ensure maximum efficiency and productivity. They offer a broad range of paper slitter knives, from standard designs to customized options to cater to the specific needs of their customers. These knives are made using top-grade materials that meet strict quality standards, ensuring they are durable, long-lasting, and can withstand constant use in harsh environments.One of the most notable features of their paper slitter knives is their precision and accuracy. The knives are designed to cut through paper and other materials with smoothness and ease, ensuring that the finished products are of excellent quality. The knives work in tandem with their cutting-edge machines, resulting in consistent and precise cuts every time.Aside from their high-quality knives, the company also offers exceptional customer service. Their team of experts is always ready to assist their clients, providing them with the necessary information and guidance they need to make the right purchasing decisions. Whether it's through phone, email, or in person, their team is dedicated to ensuring customer satisfaction.The company also invests in research and development to stay ahead of the curve in the constantly evolving industry. They continuously strive to improve their products to meet the changing demands of the market. This has resulted in the introduction of several new and innovative products in recent years that have consistently exceeded customer expectations.The company's commitment to innovation, quality, and customer service has helped them become a leading player in the paper and printing industry. With their cutting-edge technology, high-quality products, and exceptional customer service, they have gained the trust and loyalty of their customers, making them the go-to source for all their paper cutting needs.In conclusion, paper slitter knives are an essential component of the paper and printing industry, ensuring that materials are cut precisely and accurately for optimal results. For companies looking for reliable and high-quality paper slitter knives, this company offers cutting-edge innovation, top-quality materials, and excellent customer service. Their commitment to excellence has made them a trusted name in the industry, and they continue to dominate the market with their innovative products and exceptional service.

Customizable Cemented Carbide Cutter Blades and Tungsten Carbide Knives for Tip MAT Cutting Blades

Title: Enhance Precision and Efficiency with Tungsten Carbide Knives and Cemented Carbide Cutter Blades in ChinaIntroduction:In today's world, precision and efficiency are key factors in various industries, from manufacturing to construction. One critical component that ensures smooth operations and precise cuts is the Tip MAT Cutting Blade. This blog will delve into the world of Tungsten Carbide Knives and Cemented Carbide Cutter Blades, explaining their significance, applications, and why they are the preferred choice in China's industrial landscape.1. Understanding Tungsten Carbide Knives:Tungsten Carbide Knives, renowned for their exceptional hardness, durability, and wear resistance, have become a cornerstone in many industries. These knives are composed of a combination of premium-quality tungsten carbide and a bonding metal, usually cobalt or nickel. The hardness of tungsten carbide allows it to withstand high temperatures and extreme pressures, making it an excellent choice for cutting applications.2. Versatility in Cemented Carbide Cutter Blades:Cemented Carbide Cutter Blades, often referred to as tungsten carbide blades, are highly versatile due to their outstanding cutting capabilities. They are utilized in numerous industries such as paper, textile, plastic, metalworking, and more. These blades not only offer superior cutting performance but also ensure extended productivity and reduced maintenance costs.3. Customized Solutions for a Perfect Fit:The Chinese market offers a wide range of Cemented Carbide Cutter Blades in regular sizes. However, manufacturers also have the provision to supply customized Tungsten Carbide Knives as per customer specifications. By submitting your inquiry, you provide precise demands in terms of size, design, and performance requirement, enabling manufacturers to cater to your unique needs effectively.4. Applications and Benefits:4.1 Textile Industry: Tungsten Carbide Knives and Cemented Carbide Cutter Blades find extensive use in the textile sector due to their ability to cut fibers, threads, and woven materials with accuracy, resulting in enhanced production rates and improved fabric quality.4.2 Packaging Industry: These blades are crucial in the packaging industry, precisely cutting various packaging materials like cardboard, plastic, and paperboard. They deliver clean cuts, prevent product damages, and ensure packaging precision.4.3 Metalworking Industry: Tungsten Carbide Knives excel in the metalworking industry, enabling effortless cutting of different metals and alloys. Their superior wear resistance ensures prolonged blade life, allowing increased productivity and minimized downtime.4.4 Woodworking Industry: Cemented Carbide Cutter Blades offer precise and efficient wood cutting solutions. They slice through hardwoods, softwoods, laminates, and composite boards effortlessly, creating clean and accurate cuts, minimizing wastage, and optimizing output.5. Why Choose Carbide Cutter Blades?5.1 Exceptional Durability: Carbide Cutter Blades possess remarkable wear resistance and withstand extreme temperatures, ensuring longevity and reduced replacement costs.5.2 Enhanced Efficiency: These blades provide clean, precise cuts, resulting in minimal material waste, increased productivity, and improved product quality.5.3 Cost-effectiveness: Although initially pricier than conventional blades, the long-lasting performance and reduced maintenance requirements make Carbide Cutter Blades a cost-effective investment in the long run.Conclusion:In the world of precision cutting, Tungsten Carbide Knives and Cemented Carbide Cutter Blades stand tall as game-changers. Especially in China's industrial domain, these superior blades are extensively utilized, guaranteeing precision, efficiency, and customer satisfaction. Whether you require off-the-shelf sizes or customized solutions, the Chinese market caters to all your demands, ensuring your cutting needs are met comprehensively. Choose Carbide Cutter Blades and experience an unparalleled cutting revolution!

The Ultimate Guide to Double-Edge Razor Blades: Characteristics and Materials Used

Introduction to Double-Edge Razor BladesShaving has been a daily personal grooming routine for thousands of years. The invention of the razor blade has changed the way people groom themselves, and the double-edge razor blade has been a popular choice for many years. Double-edge razor blades are standardized, typically measuring 43mm long by 22mm wide by 0.1mm thick. They are made of stainless steel or carbon steel and are commonly used by people around the world.Feather Razor Blades 100Feather Razor Blades 100 is a brand of double-edge razor blades that have become the choice of many wet shavers. These razor blades are made in Japan and use high-quality Japanese stainless steel. The Feather Razor Blades 100 come in a pack of 100 blades and are suitable for all skin types.Why Choose Double-Edge Razor Blades?Double-edge razor blades are a more economical and environmentally friendly option for personal grooming. Unlike disposable razor blades that need to be thrown away after o

Hard and High-Quality Circular Cutting Knives and Blades for Various Applications

Circular knives are essential tools for many industries. They are used for a variety of cutting tasks such as cutting cartons, leather, textiles, food products and even metals. It is crucial to choose the right kind of knife for each specific task to ensure optimal performance. In this blog, we will discuss circular knives that are commonly used for cutting cartons, and specifically, the round wood saw Fujian blade, steel cutting machine for circular blade Fujian cutter, and slotting carton on scimitar.A carton cutting circular knife is a blade that is specifically designed to cut through cardboard and other similar materials. These knives are used in various industries, such as packaging, printing, and cardboard box manufacturing. These industries require a specific type of circular knife that can cut through cartons quickly and efficiently. There are different types of carton cutting circular knives, and three of the most common are the round wood saw Fujian blade, steel cutting machine for circular blade Fujian cutter, and slotting carton on scimitar.The round wood saw Fujian blade is a circular knife that is specifically designed for cutting through wood. It is made with a high-quality steel material that is durable and long-lasting. The blade has sharp teeth that can easily cut through wood without getting stuck or frayed. This blade is perfect for cutting pallets, crates, and other wooden items that are used in the packaging industry.The steel cutting machine for circular blade Fujian cutter is another type of carton cutting circular knife. This blade is designed for cutting through steel and other metals. It is made with high-quality steel that is strong and long-lasting. The blade has sharp teeth that can cut through steel quickly and efficiently without getting stuck or overheating. This blade is perfect for cutting metal sheets, pipes, and other metal items that are used in the manufacturing industry.The slotting carton on scimitar is another type of carton cutting circular knife that is commonly used in the packaging industry. This blade has a unique design that enables it to cut slits in cartons. The blade has a curved edge that is ideal for making precise cuts in cartons without damaging the contents inside. This blade is perfect for cutting slits in cartons that are used for packaging food, medicine, and other delicate items.In conclusion, choosing the right circular knife is essential for ensuring optimal performance and productivity. The round wood saw Fujian blade, steel cutting machine for circular blade Fujian cutter, and slotting carton on scimitar are three types of carton cutting circular knives commonly used in the packaging, printing, and manufacturing industries. These blades are all designed to cut through specific types of materials efficiently and effectively. So, if you need to cut cartons or other materials for your business, make sure to choose the right circular knife for your specific task. Keywords: Carton Cutting Circular Knives.

New Tapered Blade Design Enhances Bag Cutting Efficiency

Bag Taper Blade – Revolutionizing the Packaging IndustryFor businesses that deal with packaging, finding the most efficient and cost-effective solutions is essential. In recent years, Bag Taper Blade has emerged as a game-changer in the industry. This innovative product makes the process of sealing bags faster, easier, and more precise than ever before. With its exceptional performance, it has become a success story. Bag Taper Blade is a product of {company name}, a reputable manufacturer and distributor of packaging tools and accessories. The company has been providing high-quality solutions to customers for many years. They understand the needs of the packaging industry and are continually looking for ways to upgrade and enhance their product line.The Bag Taper Blade is one such product that the company has developed with a clear understanding of the packaging industry's requirements. This tool is designed to be durable, efficient, and easy to use. It is made of high-quality steel that can withstand heavy usage and endure harsh environments. The blade is also resistant to corrosion, which ensures its longevity and reliability.One of the most notable benefits of Bag Taper Blade is its speed. It can seal bags quickly and effortlessly, averting delays and increasing productivity. This is particularly beneficial for businesses that require high output while maintaining quality standards. The product has been tested and proven to work faster than traditional sealing machines, making it an excellent investment for businesses that prioritize efficiency.Another essential feature of Bag Taper Blade is its precision. The blade is designed to seal bags evenly, preventing any leaks or spillage. This means that businesses can package their products efficiently, ensuring that they maintain quality and integrity during transportation and storage. The precision of the blade also minimizes the risk of waste, which can save money for businesses in the long run.The Bag Taper Blade is also easy to use. It requires minimal training as it is straightforward and user-friendly. The blade is designed to fit onto most sealing machines, making it convenient for businesses that do not want to replace their equipment. The blade's installation process is simple and straightforward, and it can be done without the need for any additional tools.Perhaps one of the most significant advantages of Bag Taper Blade is its versatility. It can be used in a wide range of industries, including food and beverage, agriculture, pharmaceuticals, and more. The product's flexibility provides businesses with a lot of options and the ability to adapt to different packaging needs.In conclusion, the Bag Taper Blade has revolutionized the packaging industry, providing businesses with a cost-effective, efficient, and reliable sealing solution. Its numerous benefits, including speed, precision, ease of use, and versatility, make it a must-have for businesses looking to stay ahead of the curve. With its exceptional performance, Bag Taper Blade has become an industry leader, providing innovative solutions that meet the changing needs of businesses. The Bag Taper Blade is available for purchase online on {company name}'s website. Their support team is always ready to assist in choosing and installing the blade to ensure that businesses experience maximum efficiency and return on investment.