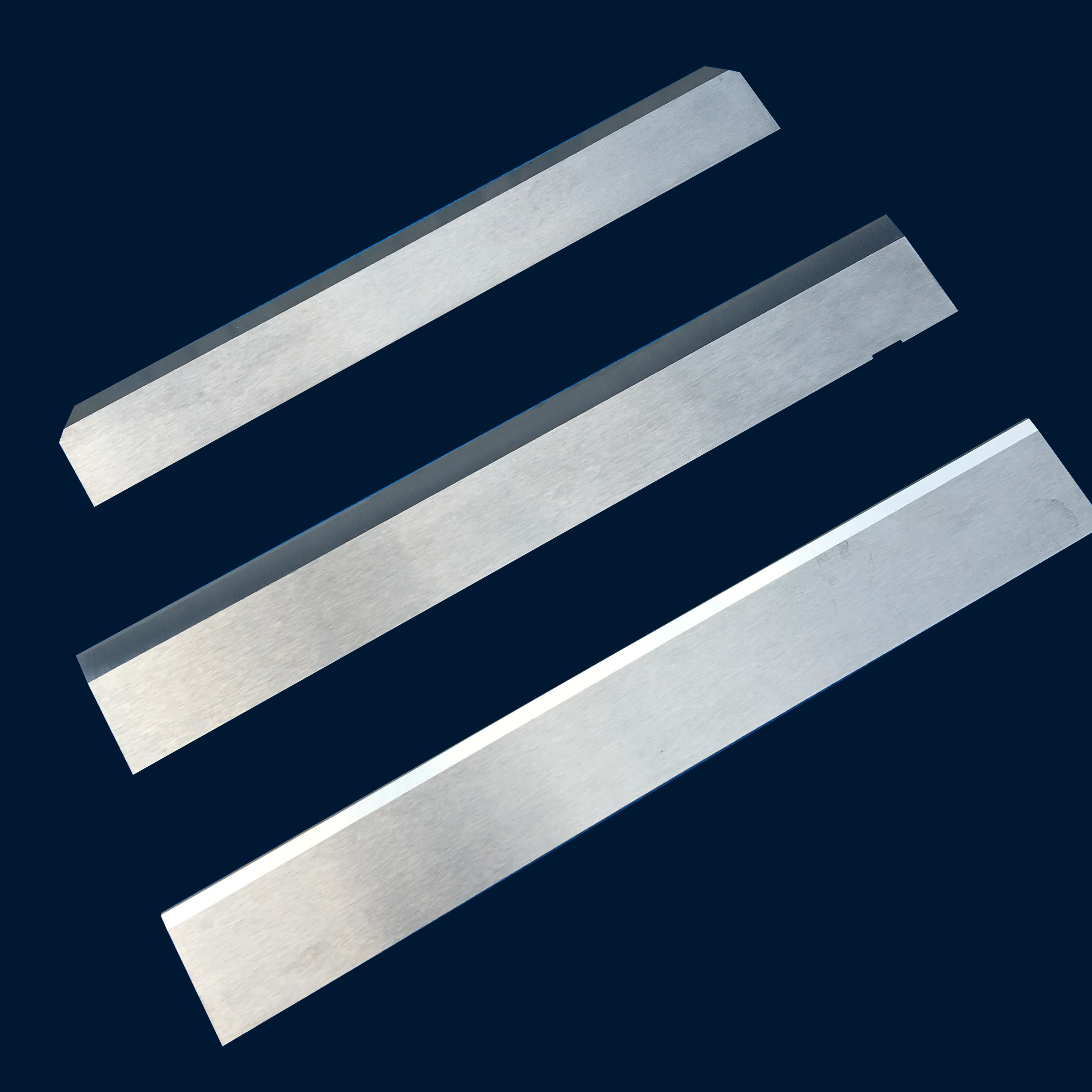

Essential Tools: Unveiling the Power of Straight Paint Scraper Blades

By:Admin

Introduction:

Painting can be a therapeutic and satisfying experience, but removing old paint or working on intricate areas can be a daunting task. That is where the Straight Paint Scraper Blades come in. Offering precision, durability, and ease of use, these paint scraper blades are revolutionizing the painting industry. In this article, we will delve into the features and benefits of these remarkable tools, ensuring that your next painting project is a breeze.

Company Introduction:

XXXX Company is a leading manufacturer of innovative painting tools and accessories. With years of experience in the industry, their products stand out for their exceptional quality, reliability, and functionality. Aimed at simplifying the painting process and improving efficiency, XXXX Company continuously endeavors to offer top-notch tools to professionals and DIY enthusiasts alike.

Features of Straight Paint Scraper Blades:

1. Unparalleled Durability: Straight Paint Scraper Blades are made from high-quality materials, ensuring exceptional longevity and resistance to wear and tear. These blades are built to last and can withstand the toughest of painting tasks.

2. Precision and Versatility: The sharp, straight edge of these paint scraper blades enables precise and accurate paint removal, even in intricate areas. Whether you need to remove paint from window frames, cabinets, or any other surface, Straight Paint Scraper Blades provide the perfect solution.

3. Ergonomic Design: Comfort matters, especially during long painting projects. Straight Paint Scraper Blades are designed with ergonomics in mind. The handles are optimized for a comfortable grip, reducing hand fatigue and making paint removal a hassle-free experience.

4. Safe and Efficient: XXXX Company prioritizes safety in their products. Straight Paint Scraper Blades feature safety caps that cover the sharp edge when not in use. This ensures protection against accidental cuts, making them safe to handle even when not wearing protective gloves.

5. Multiple Blade Sizes: Recognizing that every painting project has different requirements, Straight Paint Scraper Blades are available in various sizes. This enables users to choose the most suitable blade based on the specific task at hand, ensuring optimal performance.

Benefits of Using Straight Paint Scraper Blades:

1. Time-Saving: The sharp edge of the paint scraper blades makes the process of paint removal quick and efficient. Spending less time on this task allows for more time to focus on other aspects of your painting project.

2. Cost-Effective: With their exceptional durability, Straight Paint Scraper Blades offer a cost-effective solution for paint removal. You won't have to spend money on frequent replacements, saving you both time and money in the long run.

3. Enhanced Paint Preparation: Preparing a surface for painting is crucial for achieving a high-quality finish. The use of Straight Paint Scraper Blades ensures a smooth and clean surface, enabling better adhesion and longevity of the new paint.

4. Versatile Application: Whether you are a professional painter or a homeowner working on a DIY project, Straight Paint Scraper Blades are suitable for all skill levels. Their versatility allows you to tackle various painting tasks with ease, providing professional results every time.

Conclusion:

In the realm of painting, having the right tools can make a world of difference. Straight Paint Scraper Blades, offered by XXXX Company, provide a convenient and effective solution for any paint removal job. Empowering users with durability, precision, and versatility, these scraper blades are the choice of professionals worldwide. So, next time you have a painting project, equip yourself with Straight Paint Scraper Blades and witness the transformation of your paint removal process.

Company News & Blog

Industrial rotary files: A game-changer for metalworking tasks

Innovation is at the forefront of every industry, and the world of manufacturing is no exception. Wide range of industrial solutions are constantly being unveiled that are designed to make production processes more efficient, time-saving, and cost-effective. One such solution is the Carbide Rotary File. These files are revolutionizing the world of manufacturing and are being widely adopted by companies across the globe. Carbide Rotary Files have become an increasingly popular tool among manufacturers in recent years owing to the many advantages that they offer. They are highly versatile and are used in a variety of applications, ranging from shaping hard metals to creating intricate designs in plastics and wood. They can be used to cut, grind, deburr, shape, and finish a wide range of materials with precision and ease. Carbide Rotary Files are made using high-quality tungsten carbide, which ensures that they are highly durable, long-lasting, and can withstand heavy usage. The Carbide Rotary File is becoming an especially popular tool among manufacturers looking for a faster way to remove material during prototyping and production runs. The tool is capable of carving through metal, composites, wood, and other materials without breaking or dulling quickly, thus saving on downtime. With its speed and efficiency, it can help manufacturers achieve their desired product shape or design in a fraction of the time taken by traditional tools. Its popularity among the manufacturing community has been growing steadily ever since the Carbide Rotary File was introduced. There are several reasons why this tool is becoming increasingly preferred by manufacturers. Firstly, the Carbide Rotary Files are highly versatile. They can be used on a wide range of materials, including steel, aluminum, wood, and plastic, among others. Secondly, they are highly durable and can withstand heavy usage without breaking or dulling. This ensures that manufacturers can use the same file for multiple applications, which saves both time and money. Lastly, the Carbide Rotary Files are easy to use and can be operated by almost anyone without any specialized training or experience. In light of the growing demand for Carbide Rotary Files, several companies have started to manufacture and supply these tools. One such company is a leading supplier of cutting tools based in the United States that offers a wide range of Carbide Rotary Files. The company has over 30 years of experience in the cutting tool industry and has a proven track record of delivering high-quality tools to its clients. The Carbide Rotary Files manufactured by this company are highly rated by users and have received rave reviews. The company uses only the highest quality tungsten carbide to ensure that its files are durable, long-lasting, and can withstand heavy usage. The products are designed to offer maximum flexibility and precision while working with a variety of metals, ceramics, plastics, and composites. The company is also known for its exceptional customer service. It offers timely deliveries and ensures that its customers are satisfied with their orders and the products received. The company also provides routine maintenance for their tools to keep them in good condition and ensure they function optimally. In conclusion, the Carbide Rotary File is an essential tool for modern-day manufacturers looking for a faster and more efficient way of removing material during the prototyping and production processes. These files provide unparalleled flexibility, precision, and durability, making them an ideal solution for cutting, grinding, deburring, shaping, and finishing a wide range of materials. The Carbide Rotary Files offered by the leading supplier of cutting tools in the United States exemplify the latest in innovation and are being widely adopted by manufacturers across the globe.

Rotary Cutting Tool for Fiber Cable and Microduct: A Game-Changer in Communication Technology

In today's ever-evolving technology landscape, fiber optics has become an integral part of our daily lives. With the rise of 5G technology, high-speed internet, and faster data transfer rates, fiber optic cables have become the backbone of our digital world. However, the installation and maintenance of fiber optic cables can be a daunting task. It requires a specific set of tools and expertise to ensure smooth and uninterrupted service.One of the essential tools in the fiber optic industry is the fiber cutting blade. Fiber cutting blades are used to cut optic fibers and microducts to the required length and diameter accurately. They are used to cut fiber optic cables during installation and maintenance operations. These tools come in various forms, including handheld knives, rotary cutting tools, and specialty cutters. In this blog, we will be discussing the use of fiber cable and microduct rotary cutting tools.Fiber Cable and Microduct Rotary Cutting ToolWhen it comes to cutting fiber cables and microducts, the rotary cutting tools provide precise and efficient cutting solutions. Rotary cutting tools are an essential part of any fiber optic installer's toolkit. They are designed to provide optimal performance and ease of use when cutting through difficult materials like hardened stainless steel or dense fiber optic cables.The fiber cable and microduct rotary cutting tool come in various shapes and sizes to provide the flexibility required when working with different types of cables and microducts. These rotary cutting tools use a spinning blade to cut through the fiber optic cables or microducts. The spinning blade provides precise and smooth cuts to the cable or microduct, ensuring a clean edge that won't cause any damage to the fiber optic strands.The fiber cable and microduct rotary cutting tools come with various features that make them an ideal choice for fiber optic installers. They have an adjustable blade depth, which allows the installer to cut through different thicknesses of the cable or microduct. They also come with ergonomic handles that provide comfortable grip and reduce hand fatigue during extended usage.Another crucial feature of the fiber cable and microduct rotary cutting tools is the blade's material. The blades are made of high-quality materials that ensure durability and longevity. The blades are designed to withstand heavy usage without getting dull or damaged, ensuring a long lifespan for the tool.The fiber cutting blades used in the rotary cutting tools are designed specifically for cutting through fiber optic cables and microducts. They are designed to cut through the cable or microduct without damaging the fiber strands. The fiber cutting blades come in various shapes and sizes to accommodate different types and thicknesses of cables and microducts. They are made of high-quality materials that ensure sharpness and durability.ConclusionIn conclusion, fiber cable and microduct rotary cutting tools have become an essential tool in the fiber optic industry. They provide a precise and efficient cutting solution when working with fiber optic cables and microducts. The adjustable blade depth, ergonomic handle, and high-quality blades make these rotary cutting tools an ideal choice for fiber optic installers.If you're a fiber optic installer or technician, it's crucial to invest in high-quality fiber cutting blades and rotary cutting tools for seamless installation and maintenance operations. Choosing the right fiber cable and microduct rotary cutting tool for the job is crucial to ensure that the cable or microduct is cut with precision and care. It will not only help you save time but also ensure the fiber strands' safety and longevity.

Why Spiral Cutter Blocks are Worth the Extra Investment for Planer Thicknessers

As one of the leading companies in the woodworking industry, we are excited to announce a new addition to our collection of planer thicknessers – the revolutionary spiral cutter blocks. After years of research and development, we are confident that this new technology will make a significant difference in the quality of cutting and overall efficiency of our machines.So, what exactly is a spiral cutter block? Unlike traditional straight knives that make a flat cutting surface, spiral cutter blocks have multiple small blades arranged in a spiral pattern around the cylinder. This design results in a smoother, cleaner finish on the wood surface with reduced noise and vibration.One of the biggest advantages of spiral cutter blocks is their longer lifespan. With multiple small blades instead of a single long one, the cutter block can continue to function effectively even if one of the blades becomes dull or damaged. In contrast, a single damaged straight knife would require the entire block to be replaced. This extended lifespan translates to significant savings on maintenance costs for our customers.Additionally, the spiral cutter block reduces tear-out on the workpiece, meaning there is less wood wastage or need for rework. The cleaner cut also results in less sanding required, which again can save time and money in the long run.For our customers who are concerned about efficiency, the spiral cutter block can speed up the cutting process considerably. The multiple blades allow for deeper cuts with each pass, meaning fewer passes are required. This speeds up the overall planing process and reduces energy consumption, making it a more environmentally-friendly option.Overall, we believe that the spiral cutter block is a game-changer for the woodworking industry, and we are thrilled to be able to offer this technology with our Axminster Trade Planer Thicknessers. While there is an additional cost associated with the spiral cutter block over traditional straight knives, we believe the benefits justify the price. The much-improved finish and reduced maintenance costs are just some of the reasons why we think the investment is worthwhile.At our company, we take pride in offering the most innovative and high-quality products on the market, and the spiral cutter block is no exception. We are confident that our customers will appreciate the difference in quality and efficiency that the spiral cutter block provides.In conclusion, we invite our customers to consider the Axminster Trade Planer Thicknessers with spiral cutter blocks as the next evolution in their woodworking equipment. We are excited to be at the forefront of this revolutionary technology and look forward to seeing the benefits it brings to our customers in the years to come. Thank you for choosing our products, and we look forward to continuing to serve you with the best woodworking tools available.

Discover the Latest Innovations in Chemical Fiber Cutting Blades

Chemical Fiber Cutting Blades Revolutionize Textile IndustryIn an age where innovation often defines success, the introduction of Chemical Fiber Cutting Blades has revolutionized the textile industry, marking a new era of efficiency, precision, and productivity. These state-of-the-art blades, developed by an industry-leading company, have paved the way for enhanced manufacturing processes, providing countless advantages to textile producers worldwide.With a company history spanning over several decades, our visionary partner has consistently remained at the forefront of research, development, and innovation. Known for their commitment to excellence, they have garnered a strong reputation as a trusted provider of cutting-edge solutions to the textile sector. Their latest breakthrough, the Chemical Fiber Cutting Blades, exemplifies their dedication to advancing industry standards and meeting customer demands.The Chemical Fiber Cutting Blades are manufactured using the latest techniques and highest quality materials, ensuring exceptional performance and durability. Designed specifically for textile applications, these blades demonstrate unparalleled cutting precision and longevity. Their innovative composition incorporates meticulous engineering, resulting in blades that are resistant to wear, deformation, and corrosion, guaranteeing optimal performance even under demanding conditions.One of the most notable features of these cutting blades is their ability to seamlessly cut a wide range of chemical fibers with exceptional accuracy. Traditional blades often struggle with high-speed cutting operations, leading to uneven cuts, fraying, and damaged fibers. However, the Chemical Fiber Cutting Blades use a revolutionary cutting edge design that minimizes friction and heat, allowing for faster, smoother, and more precise cutting. This translates to significant time and cost savings for textile manufacturers, as well as improved product quality.Furthermore, these blades possess outstanding flexibility, making them suitable for a myriad of textile applications. Whether it's cutting fibers for apparel, upholstery, home textiles, or industrial fabrics, the Chemical Fiber Cutting Blades consistently deliver outstanding results. Their versatility allows manufacturers to streamline their production processes, reduce downtime, and maximize output, ultimately leading to increased profitability and competitiveness.In addition to their cutting-edge design, these blades are also easy to install, maintain, and replace, ensuring uninterrupted production cycles. With minimal downtime and reduced maintenance requirements, textile manufacturers can enhance their overall operational efficiency and meet demanding market demands without compromising on quality.Safety is a top priority for any manufacturing facility, and the development of these blades has also taken this crucial factor into account. The Chemical Fiber Cutting Blades are carefully engineered to prioritize operator safety, featuring protective measures such as anti-kickback properties and noise reduction technologies. This commitment to safety not only safeguards the well-being of workers but also minimizes the risk of accidents or injuries, resulting in improved workplace environments.As textile producers continue to grapple with increasing competition and customer expectations, the introduction of Chemical Fiber Cutting Blades offers a compelling solution. By enhancing cutting precision, efficiency, and durability, these blades enable manufacturers to optimize their processes and deliver superior products to the market. With the continued support and innovation from our visionary partner, the textile industry can anticipate a bright and prosperous future, marked by advancements that reshape the way we manufacture and consume textiles.

The Ultimate Guide to Double-Edge Razor Blades: Characteristics and Materials Used

Introduction to Double-Edge Razor BladesShaving has been a daily personal grooming routine for thousands of years. The invention of the razor blade has changed the way people groom themselves, and the double-edge razor blade has been a popular choice for many years. Double-edge razor blades are standardized, typically measuring 43mm long by 22mm wide by 0.1mm thick. They are made of stainless steel or carbon steel and are commonly used by people around the world.Feather Razor Blades 100Feather Razor Blades 100 is a brand of double-edge razor blades that have become the choice of many wet shavers. These razor blades are made in Japan and use high-quality Japanese stainless steel. The Feather Razor Blades 100 come in a pack of 100 blades and are suitable for all skin types.Why Choose Double-Edge Razor Blades?Double-edge razor blades are a more economical and environmentally friendly option for personal grooming. Unlike disposable razor blades that need to be thrown away after o

Exploring the Thrilling World of Black-Clad Heroes

Glorious Trash: Good Guys Wear Black - The Chuck Norris Tie-In You Need to ReadChuck Norris has been a cultural icon for several decades now, and his larger-than-life persona has continued to inspire countless fans around the world. The former martial arts champion turned movie star has appeared in several iconic films throughout his career, and one of the most memorable ones has to be Good Guys Wear Black.The movie, which was released in 1978, was a classic action flick that showcased Norris' impressive skills as a martial artist and actor. It was also turned into a novel by Max Franklin, and the tie-in edition remains a must-read for any Chuck Norris fan.So, what makes Good Guys Wear Black such a great read? Well, for starters, the book offers a more in-depth look into the story and characters than the movie could. The novelization fleshes out the plot and gives readers a more nuanced understanding of the events that unfold.Moreover, the book is written in a style that perfectly captures the tone and pace of the movie. It's fast-paced, action-packed, and filled with witty one-liners that are quintessential Norris. The writing is also surprisingly well-crafted, which makes for an engaging and enjoyable reading experience.However, the real highlight of Good Guys Wear Black is undoubtedly Chuck Norris' performance. The book manages to capture the essence of his character and his unique fighting style, making it a must-read for any fan of his work. Whether you're a long-time Chuck Norris aficionado or new to the world of martial arts movies, this tie-in edition is sure to impress.Another exciting aspect of Good Guys Wear Black is the fight scenes. In particular, Norris' use of a "good wear life blade" is a thrilling addition that adds an extra layer of excitement to the action sequences. The weapon is described in detail in the book, making it a memorable feature of the story.In conclusion, if you're a fan of Chuck Norris or just love a good, action-packed read, Good Guys Wear Black is a must-have addition to your bookshelf. The tie-in edition perfectly captures the essence of the movie and offers readers an engaging and enjoyable reading experience. So, go ahead and add this glorious trash to your collection - you won't regret it!

Low Price High Quality Carbon Steel Blade Paint Scraper Wholesale from China Suppliers and Manufacturers - JCK Industrial Razor Blade Scraper

China’s Economy Continues to Grow Through Its Low Price High Quality Putty Knife Carbon Steel Blade Paint ScraperChina is known for its low cost and high-quality products, from electronics to daily household goods, and now the paint scraper blade tools that have become increasingly popular across the world. These tools have proven to be quick and easy to use, and for the best product on the market, consumers look no further than JCK Industrial Razor Blade Scraper’s China high-quality putty knife carbon steel blade paint scraper.With the increasing demand for this quality manual scraper, JCK Industrial Razor Blade Scraper is without a doubt the best paint scraper supplier and manufacturer in China. They offer high-quality putty knife carbon steel blade paint scrapers that have been designed to cater to every need of their customers – their products are lightweight, easy to use, and durable.The company’s wide-blade scraper design is ideal for quickly removing paint and stickers, while the soft-grip glass scraper is perfect for those tough and hard-to-reach spots. JCK Industrial Razor Blade Scraper has designed their paint scraper blades with their customers’ needs in mind. The result is a product that delivers premium-quality performance and durability while still retaining the perfect design for scratch-free experience.The company is dedicated to providing customers with only the best and highest-rated product. Their paint scraper is a testament to their commitment and dedication to quality and excellence. With the use of high-quality materials combined with the latest engineering techniques, JCK Industrial Razor Blade Scraper has designed a product that is not only highly effective but also has the potential to last a very long time.Not only is JCK Industrial Razor Blade Scraper providing a high-quality product, they are also producing them at an affordable price. As a reliable and professional manufacture of putty knife carbon steel blade paint scraper in China, JCK Industrial Razor Blade Scraper’s mission is to offer their customers, high-quality products without blowing their budget.The company has achieved this feat through the use of modern and automated production lines, mass production, and bulk purchasing of raw materials. This is why JCK Industrial Razor Blade Scraper’s products are not just affordable but are highly competitive in today’s market.Having been in the industry for well over a decade, JCK Industrial Razor Blade Scraper has engaged local and international partners and suppliers to deliver only the best to their customers. These partners are highly skilled and experienced individuals committed to the same goal: providing high-quality, reliable, and affordable putty knife carbon steel blade paint scrapers to the market.Their paint scraper blade is available wholesale, meaning they can provide to businesses and companies in bulk orders at an affordable rate. Customers get to purchase JCK Industrial Razor Blade Scraper’s high-quality paint scraper blades in the desired quantity for their businesses at a discounted rate.With their high-quality putty knife carbon steel blade paint scraper, JCK Industrial Razor Blade Scraper is not only providing the current market with a durable and efficient product, but they are also doing their part in growing China’s economy. The company employs skilled and technical staff to ensure a quality product that will take the market by storm.JCK Industrial Razor Blade Scraper has become a force to reckon within the industry, not just in China but the world market as well. Their paint scraper blades have passed international safety and quality assurance tests, making it one of the available premium-quality products worldwide. For anyone in the market looking for a high-quality putty knife carbon steel blade paint scraper, JCK Industrial Razor Blade Scraper is the place to go. They offer quality, durability, and an affordable product that with time will gently scuff your painting projects whenever required for years.

Custom Blades for Textile Cutting: Find the Perfect Fit for Your Application

In today's world, technology has influenced every aspect of our daily lives, including the textile industry. Custom machine knives for cutting textiles are essential for the creation of high-quality textiles quickly and accurately. York Saw is a renowned manufacturer of industrial blades that can be customized to fit specific textile cutting applications. Their expertise and capabilities make them an ideal partner for textile manufacturers looking to improve their operations.York Saw has been a leader in the blade industry for over 100 years. Their experience and knowledge of blade manufacturing has allowed them to create some of the most durable and reliable blades in the market. Their quality control measures ensure that their products perform to the highest standards for years to come.The importance of precise cutting in the textile industry cannot be overemphasized. When it comes to cutting fabric, accuracy and precision are crucial. In the past, manual cutting was the only option available. However, with technological advancements, the use of cutting machines has become the norm. These machines have revolutionized the textile industry by allowing for increased productivity, efficiency, and accuracy.The blades used in cutting machines play a vital role in determining the quality of fabric cut. The blade must be sharp and durable enough to cut through the fabric without causing any damage. If the blade is blunt or ineffective, it can cause significant issues, including jagged edges, uneven cuts and can even damage the fabric.York Saw provides high-quality industrial blades that are specifically designed for textile cutting applications. They offer a wide range of blades in different sizes, materials, thicknesses, and designs to meet the unique needs of each customer. The blades can be customized to suit the specific requirements of the textile manufacturer, including the material being cut, the thickness of the fabric, and the desired cutting speed. York Saw uses the latest technology to manufacture their blades, including automated machines that produce precise and accurate blades repeatedly. They also have an in-house team of experts that work with each customer to understand their unique needs and provide the appropriate solution. By working closely with their customers, they can develop a blade that meets their precise requirements and provides optimal performance, resulting in an increase in productivity and cost savings.In summary, York Saw is a leading manufacturer of industrial blades for textile cutting applications. Their commitment to quality, reliability, and precision has made them a trusted partner for textile manufacturers worldwide. They understand that every customer has unique needs, and they are dedicated to providing personalized solutions that meet their specific requirements. Their expertise and capabilities make them an ideal partner for anyone looking to improve their textile cutting operations. Contact York Saw today to learn more about how they can help with bespoke machine knives for cutting textiles.

New Study Finds Majority of Beer Drinkers Prefer Craft Over Traditional" could be rewritten as "Majority of Beer Drinkers Favor Craft Beers in New Study".

[News Title]Cutting-Edge Cutter Technology Revolutionizing Industries: A Comprehensive Look into the Innovations of [Company][News Introduction]In today's rapidly evolving technological landscape, [Company] has been making significant waves with its groundbreaking cutter technology. Pioneering in several industries, [Company] has successfully transformed the way companies and individuals approach cutting tasks. With their advanced innovations, they have not only simplified and expedited operations but also ensured heightened precision and safety. Let's delve deeper into the revolutionary developments brought about by [Company] and the significant impact they have had on various sectors.[Company Background]Established in [Year], [Company] has spent years at the forefront of research and development to create cutting-edge cutter solutions. The company's vision is to reshape industries by providing cutting technology that surpasses existing benchmarks, revolutionizing efficiency, and enhancing operational safety. Utilizing a team of expert engineers and adopting state-of-the-art manufacturing techniques, [Company] has consistently pushed boundaries to deliver cutting solutions that cater to a wide range of applications.[Segment 1: Industrial and Manufacturing Sector]With their innovative cutter technology, [Company] has significantly transformed the industrial and manufacturing sector. By leveraging precision laser cutting, their equipment has enabled manufacturers to achieve unparalleled accuracy and efficiency in their production processes. These advanced solutions have allowed companies to minimize material waste and streamline operations, resulting in cost savings and improved productivity. Additionally, [Company's] cutting tools are designed to integrate seamlessly with industrial automation systems, further enhancing overall productivity.[Segment 2: Medical and Healthcare Sector]Recognizing the unique requirements of the medical and healthcare sector, [Company] has developed cutting solutions that are reshaping surgical procedures. By incorporating robotics and artificial intelligence, their cutters have revolutionized precision and safety in the operating room. Surgeons can now rely on [Company's] technology to perform intricate surgeries with unparalleled accuracy, resulting in improved patient outcomes and reduced recovery periods. Furthermore, the incorporation of advanced safety features ensures minimal risk during procedures, guaranteeing the well-being of both patients and medical professionals.[Segment 3: Construction and Architecture Sector]In the construction and architecture sector, [Company] has introduced cutter technology that has transformed the way projects are executed. With their efficient and high-precision tools, contractors can now tackle complex cutting tasks with ease. This has vastly improved the accuracy of project execution, leading to optimal results and reducing instances of rework. Moreover, [Company's] wide range of cutting solutions caters to different construction materials, allowing contractors to meet diverse project requirements while ensuring timeliness and cost-effectiveness.[Segment 4: Arts and Crafts]Not limited to industrial applications, [Company] has also made a significant impact in the arts and crafts community. By offering cutting tools that are user-friendly and versatile, artists and crafters can bring their intricate designs to life. [Company's] cutters are equipped with intuitive software, allowing creators to effortlessly design and execute complex patterns. This advancement has not only provided artists with enhanced creative freedom but has also accelerated the production of intricate and precise crafts.[Segment 5: Sustainable Manufacturing]In line with growing concerns for environmental sustainability, [Company] has integrated eco-friendly practices into their manufacturing processes. Through the use of energy-efficient technologies and sustainable materials, [Company's] cutters contribute to minimizing carbon footprints. Their commitment to sustainability extends beyond their manufacturing practices, as they continuously strive to develop techniques that promote recycling and waste reduction in various industries.[Conclusion]With their groundbreaking cutter technology, [Company] has revolutionized various industries, from manufacturing and healthcare to construction and arts. Through continuous innovation, the company has positioned itself as a global leader in advanced and efficient cutting solutions. As [Company] continues to push boundaries, the future of cutting technology appears full of promise, with further advancements poised to reshape industries and unlock new possibilities across multiple sectors.

The Advantages of a Tungsten Carbide Knife Revealed in Latest News

Tungsten Carbide Knife: Revolutionizing Precision CuttingIn recent years, the field of precision cutting has witnessed astounding advancements. One such innovation is the Tungsten Carbide Knife, a cutting-edge tool that has revolutionized various industries. With its exceptional durability, sharpness, and versatility, this remarkable blade has quickly become the go-to choice for professionals in fields ranging from aerospace engineering to surgical procedures.The Tungsten Carbide Knife, a remarkable creation of multiple cutting-edge technologies, is composed of tungsten carbide, a hard and dense material that exhibits immense strength and resistance to wear. This unique combination of strength and durability makes it perfect for applications that require sustained high-performance cutting.What sets the Tungsten Carbide Knife apart from other cutting tools is its exceptional sharpness. With a hardness level close to that of a diamond, this knife boasts an unbeatable cutting edge that remains sharper for longer compared to traditional blades. This sharpness not only ensures precision and accuracy in every cut but also eliminates the need for constant sharpening, saving both time and costs for its users.Moreover, the versatility of the Tungsten Carbide Knife is another factor contributing to its widespread adoption across various industries. Whether it be slicing through tough materials like steel or delicate procedures such as intricate surgical incisions, this revolutionary blade can handle it all. Its adaptability has made it indispensable in fields like aerospace engineering, metal fabrication, woodworking, and even culinary arts.The aerospace industry has greatly benefited from the Tungsten Carbide Knife's exceptional cutting performance. During the manufacturing process of aircraft components, precision is of utmost importance to ensure the safety and integrity of the final product. The sharpness and durability of this knife make it an invaluable tool for cutting materials like carbon fiber composites and titanium alloys with utmost precision and efficiency.Metal fabricators have also found the Tungsten Carbide Knife to be a game-changer. It enables them to effortlessly cut through hardened steel, reducing production time and improving overall efficiency. Additionally, its long-lasting sharpness minimizes the need for blade replacements or frequent resharpening, resulting in significant cost savings.Woodworking enthusiasts have also hailed the Tungsten Carbide Knife as one of the most essential tools in their repertoire. Its ability to cut through various types of wood with precision and ease allows craftsmen to create intricate designs and achieve exceptional finishes. The durability of the blade ensures that it can handle prolonged use, even on denser wood species, without losing its sharpness or structural integrity.In the field of medicine, the Tungsten Carbide Knife has become a staple tool for surgeons performing intricate procedures. Its outstanding sharpness and resistance to wear enable precise incisions, reducing the risk of tissue damage and minimizing patient recovery time. Furthermore, the knife's resistance to corrosion ensures that it can be safely sterilized for reuse, providing a cost-effective solution for hospitals and medical facilities.As demand for precision cutting solutions continues to rise, manufacturers have capitalized on the potential of the Tungsten Carbide Knife. Companies such as [Company Name] have honed their expertise in producing these exceptional blades, combining cutting-edge technologies with intricate craftsmanship. From material selection to the final finishing, every step of the manufacturing process at [Company Name] ensures that their Tungsten Carbide Knives meet the highest standards of quality and performance.With dedicated research and development efforts, [Company Name] continuously pushes the boundaries of what is possible with the Tungsten Carbide Knife. By incorporating user feedback and advanced manufacturing techniques, they strive to improve the blade's performance, lifespan, and versatility. As a result, [Company Name] has become a trusted name in the industry, providing professionals across various fields with reliable and exceptional cutting solutions.In conclusion, the Tungsten Carbide Knife has revolutionized precision cutting in multiple industries. Its unparalleled durability, sharpness, and versatility have made it the go-to tool for professionals in aerospace engineering, metal fabrication, woodworking, and medicine. Manufacturers like [Company Name] have played a crucial role in the widespread adoption of this remarkable blade, constantly pushing the boundaries of its capabilities. As technology continues to advance, we can expect the Tungsten Carbide Knife to further evolve, revolutionizing precision cutting even more in the years to come.