Enhance Efficiency and Precision with Top-notch Corrugated Cutting Tools

By:Admin

The packaging industry has been enjoying significant growth over the past few years, fueled by the ever-increasing demand for consumer goods. With the rise of e-commerce and online shopping platforms, packaging has become more important than ever, and corrugated boxes have emerged as the most popular packaging solution in the market. Corrugated boxes are made of fluted paperboard that offers superior strength, durability, and protection.

However, the manufacturing process of corrugated boxes requires cutting, scoring, and trimming processes that involve the use of special cutting tools. Corrugated cutting tools play a vital role in the packaging industry, enabling companies to create customized and efficient packaging solutions that meet the needs of their clients.

One of the leading manufacturers of corrugated cutting tools in the market is a company that has been serving the packaging industry for over 30 years. The company specializes in the production of rotary and flat dies, crush cutters, and saw blades that are designed to meet the unique demands of corrugated box manufacturing.

With a team of experienced engineers and technicians, the company is committed to providing cutting-edge solutions that enhance the efficiency, productivity, and profitability of the packaging industry. Their products are made from high-quality materials that ensure superior performance, durability, and reliability.

The company’s rotary and flat dies are designed to produce high-quality boxes with precise dimensions and clean edges. Their crush cutters are specifically engineered to cut through multiple layers of corrugated board without damaging the flute structure. They also offer a range of saw blades that can cut through different materials, including corrugated boards, plastics, and metals.

Their products are optimized for speed, precision, and durability. With the latest technology and state-of-the-art manufacturing facilities, they can deliver customized solutions that meet the specific needs of their clients. Whether it’s a new packaging design, a modification to an existing die, or a repair of a damaged die, the company can provide quick and cost-effective solutions that minimize production downtime.

The company understands that the packaging industry is highly competitive, and every second counts. That’s why they have invested heavily in research and development, ensuring that their products are at the forefront of innovation. They constantly explore new materials, designs, and manufacturing processes that can help their clients gain a competitive edge in the market.

In addition to manufacturing cutting tools, the company also provides technical support, training, and maintenance services to their clients. They have a team of qualified engineers and technicians who can assist with die set up, machine optimization, and troubleshooting. They also offer training programs that equip clients with the knowledge and skills needed to operate and maintain their machines effectively.

Furthermore, the company is committed to sustainability and environmental responsibility. They use eco-friendly materials and processes in their manufacturing operations, minimizing waste and reducing their carbon footprint. They also encourage their clients to adopt sustainable packaging practices that protect the environment and promote a circular economy.

In conclusion, corrugated cutting tools play a crucial role in the packaging industry, and companies that specialize in the manufacture of these tools are essential for the success of the industry. With their commitment to innovation, quality, and customer satisfaction, the company has established itself as a leader in the market, providing cutting-edge solutions that enable their clients to create customized and efficient packaging solutions that meet the needs of their customers.

Company News & Blog

Experts reveal the dangers of unregulated razor knives in China

China Razor Knife continues to revolutionize the cutting tool industry with its innovative designs and exceptional quality. As a leading manufacturer and exporter of cutting tools, the company has gained a reputable position in the global market.Established over two decades ago, China Razor Knife has continuously strived to meet the ever-evolving needs of its customers. With a commitment to providing top-notch products, the company has invested heavily in research and development, continuously seeking improvements in design and manufacturing processes. This dedication has resulted in a diverse range of cutting tools that are widely recognized for their durability, precision, and safety.One of the key factors that sets China Razor Knife apart from its competitors is its emphasis on safety. The company understands the potential risks associated with cutting tools and has implemented stringent quality control measures to ensure the safety of its products. Each knife undergoes rigorous testing and quality inspections before it reaches the market, guaranteeing that customers receive only the highest quality tools. Additionally, China Razor Knife provides comprehensive user manuals and safety guidelines to educate users on proper handling and precautions.In line with its commitment to innovation, China Razor Knife has recently introduced a revolutionary new blade design. This blade incorporates advanced materials and cutting-edge technology to enhance the cutting experience. With improved sharpness, durability, and precision, this new blade offers users a superior cutting performance that is unmatched in the industry. The company's dedication to innovation has not only improved the functionality of its products but has also contributed to a more efficient and enjoyable cutting experience for its customers.With a strong focus on customer satisfaction, China Razor Knife offers a wide range of cutting tools suitable for various applications. From utility knives to box cutters, the company provides tools that cater to the needs of professionals and homeowners alike. Whether it's for industrial use, home improvement projects, or everyday tasks, China Razor Knife has a solution to meet every cutting need.Furthermore, China Razor Knife is committed to environmental sustainability. The company adheres to strict environmental regulations and employs environmentally friendly manufacturing practices. Using eco-friendly materials and production methods, China Razor Knife minimizes its carbon footprint and contributes to a greener future.The success and global recognition of China Razor Knife can be attributed to its unwavering commitment to excellence. With a vision to become the leading provider of cutting tools worldwide, the company continues to push the boundaries of innovation and quality. Through continuous research, development, and investment in cutting-edge technology, China Razor Knife remains at the forefront of the industry.In conclusion, China Razor Knife stands as a shining example of China's commitment to manufacturing excellence. With its unwavering dedication to quality, safety, innovation, and customer satisfaction, the company continues to redefine the cutting tool industry. As China Razor Knife continues to introduce groundbreaking designs and superior cutting performance, it is poised to maintain its position as a global leader in the years to come.

Explore the Ultimate Collection of Reaktor Razor Synth Patches

for Reaktor and Kilomash.The Best Razor Blades for Reaktor - A ReviewWhen it comes to creating outstanding electronic music, having the right tools in your arsenal is essential. One such tool that has gained immense popularity over the years is the ADSR Razor Synth. This virtual instrument is known for its highly unique sound design capabilities and has been used by some of the biggest names in the industry.However, to truly make the most of the Razor Synth, you need to have the right sound patches. And this is where the Razor Blades collection comes in. Created by renowned producer and sound designer Kilomash, this collection includes 62 ultra-high-quality patches that take the Razor Synth's sound capabilities to new heights.The patches in the Razor Blades collection are incredibly diverse and cover a wide range of electronic music genres, from techno to dubstep and beyond. Each patch has been carefully crafted to deliver maximum impact while ensuring that every detail of the sound is perfect.One of the standout features of the Razor Blades collection is its use of bespoke wavetables. These wavetables have been designed specifically for the Razor Synth and offer a uniquely rich and dynamic sound that is unlike anything else out there.Kilomash's attention to detail is evident in every patch in the Razor Blades collection. From the perfectly balanced basslines to the complex synth leads, each sound has been meticulously crafted to deliver an exceptional sonic experience.But the real beauty of the Razor Blades collection lies in how easy it is to use. Whether you're a seasoned producer or just starting out, these patches enable you to create professional-level sounds effortlessly.In conclusion, the Razor Blades collection is undoubtedly one of the Best Razor Blades collections available for Reaktor. Kilomash's expert sound design skills and attention to detail have resulted in a collection of patches that will take your electronic music productions to new heights. Whether you're looking to create cutting-edge techno or hard-hitting dubstep, the Razor Blades collection has you covered. So, it's time to take your productions to the next level with the Best Razor Blades for Reaktor.

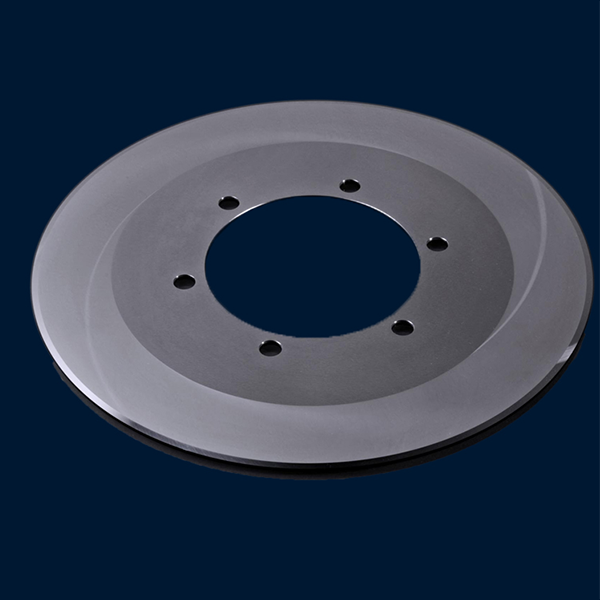

Circular Blades for Cigarette Filter Rod Cutting: Tungsten Carbide Circular Cutting Knives in 88x16x0.25mm Size

Eight Cutters Inc. is proud to announce its latest addition to its extensive range of cutting tools – the 88x16x0.25mm circular blades, made from Tungsten Carbide. With the increased demand for cigarette filtering machinery in recent years, these blades are the most suitable tools to process cigarette filters.At Eight Cutters Inc., we are committed to delivering premium quality cutting tools for various industries. Our Tungsten Carbide circular blades are the result of years of research, development, and experience in the cutting tool industry. We have invested in advanced technology and equipment to ensure that our clients receive top-quality products that meet their industry’s specific requirements.The regular size of the slitting knives is OD88xID16xTHK0.26mm. However, we can customize them based on your specific needs. Our tungsten carbide blades are renowned for their incredible durability, resistance to wear, and high-quality finishes. These blades are designed to provide precision cuts, reduce the need for frequent blade changes, and optimize your cutting process’s productivity.Tungsten carbide is the primary material used in these blades as it is a high-performance material that offers superior durability and wear resistance. Its unique properties make it ideal for use in the high-speed cutting of cigarettes. The blades are also manufactured to the highest standards, making them easy to adjust and maintain, ensuring precision in every cut.Our 88x16x0.25mm circular blades are the perfect fit for cigarette filter rod cutting, as they offer clean and precise cuts for high-speed cigarette manufacturing machinery. Our blades are also versatile enough to be employed in different cutting processes, making them an essential tool for a wide range of industries.We are proud to hold a reputation for quality, reliability, and efficiency, and at Eight Cutters Inc., we continuously strive to exceed our customers’ expectations. Our cutting tools are always available and ready for shipping to our customers worldwide. When you choose us, rest assured that our customer support team is available to provide prompt support and solutions to any queries or issues you may have.Our products are accessible to clients all over the globe, and we offer flexible shipping and payment options to make sure that our customers receive the products at their convenience. You can order our Tungsten Carbide blades directly from our website or through our sales team. Our team is always available to discuss your needs and suggest the best tooling solutions for your applications.In conclusion, the 88x16x0.25mm circular blades manufactured from Tungsten Carbide are the most suitable tool for processing cigarettes and other filter rods. Eight Cutters Inc. is proud to be at the forefront of the cutting tool industry, delivering top-quality cutting tools to different industries worldwide. We value our customers’ satisfaction and continuously work towards improving our products and services to meet their evolving needs. Choose us today and experience the difference in our top-quality cutting tools.

How to Cut Holes in Cement Backer Board with a Jigsaw: A Homeowner's Guide to Cutting Hardie Backer Board. Blade Options for Cutting Cement Backer Board.

for Effective Backer Board Installation. When it comes to installing tile or other types of flooring in your home, proper preparation is essential for a successful outcome. One of the most important steps is installing the right backer board. Hardie board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. However, cutting Hardie backer board can be a challenge without the right tools and techniques. In this post, we will discuss how to cut holes in cement backer board with a jigsaw and the importance of choosing the right Hardie plank cutting blade.Cutting Holes in Cement Backer Board with a JigsawMany DIY enthusiasts and professional contractors alike prefer using a jigsaw for cutting holes in cement backer board. With its fine-toothed blade, a jigsaw can make precise cuts quickly and easily. To get started, you will need the following tools:- A jigsaw with a fine-toothed blade - A straight edge - Safety glasses - Dust mask - Gloves Here are the steps to follow:1. Place the cement backer board on a work surface, such as a sawhorse or workbench.2. Use a straight edge to mark the shape of the hole you want to cut 3. Put on your safety glasses, dust mask, and gloves 4. Insert the jigsaw blade into the hole you have drilled in the cement backer board 5. Turn on the jigsaw and follow the outline you have marked on the backer board 6. Apply firm and steady pressure as you cut through the cement backer board Choosing the Right Hardie Plank Cutting BladeTo achieve a clean cut on your cement backer board, you must use the right type of blade. A Hardie plank cutting blade is specially designed to cut through fiber cement products like Hardie board. Here are some factors to consider when choosing the right blade:- Tooth configuration: The blade should have a double-row configuration with extra-sharp teeth to prevent chipping and splintering - Diameter: The diameter of the blade must be suitable for the type of tool you are using - Material: Choose a blade made of high-quality carbide-tipped material, which is durable and long-lasting In summary, Hardie backer board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. Cutting holes in cement backer board with a jigsaw is a great option for those who prefer a fine-toothed blade. To achieve a clean cut, it is essential to choose the right Hardie plank cutting blade. With these tips in mind, you can install your Hardie backer board with ease and confidence.

Enhance Efficiency and Precision with Top-notch Corrugated Cutting Tools

Corrugated Cutting Tools Support the Packaging IndustryThe packaging industry has been enjoying significant growth over the past few years, fueled by the ever-increasing demand for consumer goods. With the rise of e-commerce and online shopping platforms, packaging has become more important than ever, and corrugated boxes have emerged as the most popular packaging solution in the market. Corrugated boxes are made of fluted paperboard that offers superior strength, durability, and protection.However, the manufacturing process of corrugated boxes requires cutting, scoring, and trimming processes that involve the use of special cutting tools. Corrugated cutting tools play a vital role in the packaging industry, enabling companies to create customized and efficient packaging solutions that meet the needs of their clients.One of the leading manufacturers of corrugated cutting tools in the market is a company that has been serving the packaging industry for over 30 years. The company specializes in the production of rotary and flat dies, crush cutters, and saw blades that are designed to meet the unique demands of corrugated box manufacturing.With a team of experienced engineers and technicians, the company is committed to providing cutting-edge solutions that enhance the efficiency, productivity, and profitability of the packaging industry. Their products are made from high-quality materials that ensure superior performance, durability, and reliability.The company’s rotary and flat dies are designed to produce high-quality boxes with precise dimensions and clean edges. Their crush cutters are specifically engineered to cut through multiple layers of corrugated board without damaging the flute structure. They also offer a range of saw blades that can cut through different materials, including corrugated boards, plastics, and metals.Their products are optimized for speed, precision, and durability. With the latest technology and state-of-the-art manufacturing facilities, they can deliver customized solutions that meet the specific needs of their clients. Whether it’s a new packaging design, a modification to an existing die, or a repair of a damaged die, the company can provide quick and cost-effective solutions that minimize production downtime.The company understands that the packaging industry is highly competitive, and every second counts. That’s why they have invested heavily in research and development, ensuring that their products are at the forefront of innovation. They constantly explore new materials, designs, and manufacturing processes that can help their clients gain a competitive edge in the market.In addition to manufacturing cutting tools, the company also provides technical support, training, and maintenance services to their clients. They have a team of qualified engineers and technicians who can assist with die set up, machine optimization, and troubleshooting. They also offer training programs that equip clients with the knowledge and skills needed to operate and maintain their machines effectively.Furthermore, the company is committed to sustainability and environmental responsibility. They use eco-friendly materials and processes in their manufacturing operations, minimizing waste and reducing their carbon footprint. They also encourage their clients to adopt sustainable packaging practices that protect the environment and promote a circular economy.In conclusion, corrugated cutting tools play a crucial role in the packaging industry, and companies that specialize in the manufacture of these tools are essential for the success of the industry. With their commitment to innovation, quality, and customer satisfaction, the company has established itself as a leader in the market, providing cutting-edge solutions that enable their clients to create customized and efficient packaging solutions that meet the needs of their customers.

Industrial Quality Solid Carbide Ball End Insert Knives for CNC Router Bits and Tooling

, CNC Router Bits, Industrial CNC Tooling, Amana Tool, Saw Blades, Shaper Cutters, Boring Bits, Planer and Jointer Knives.If you need to machine materials that are tough, abrasive, or hard to cut effectively, then you need the right tools for the job. Solid carbide insert knives offer several advantages over traditional cutting tools. They can increase your productivity, reduce your downtime, and enhance your cutting performance. At Amana Tool, we offer a wide range of industrial-quality router bits, CNC router bits, saw blades, shaper cutters, boring bits, and planer and jointer knives that meet the needs of any woodworking or manufacturing application.Our Solid Carbide Ball End Insert CNC Replacement Knives are a perfect example of the precision and durability that our products offer. These knives are designed to fit into standard CNC routers and offer superior cutting performance in materials like aluminum, hardwoods, MDF, particle board, and more. They are also ideal for cutting through difficult materials such as plastics, foam, and composites.The Solid Carbide Insert Knives used for these replacement knives are made from premium grade carbide materials that are designed to withstand repeated use and last longer than traditional cutting tools. This industrial-grade material is extremely hard and wear-resistant, which means that it holds its cutting edge longer and can deliver more precise cuts for longer periods of time.These insert knives also offer a significant improvement in cutting performance over traditional cutting tools. The unique design and sharp edge of these knives enable them to slice through materials with ease, without generating excessive heat or friction. This enables you to achieve a smoother, more accurate finish, even on difficult-to-cut materials.Our CNC Router Bits and Industrial CNC Tooling are world-renowned for their quality and precision. They are made with the highest quality materials and manufacturing processes to ensure that they meet the high demands of our industrial customers. Our tools are designed to be easy to use, with a range of sizes and configurations to meet any application.Our Saw Blades are also designed to deliver superior cutting performance in various materials, including hardwoods, softwoods, plastics, and more. Our blades are made from the best quality materials that provide the perfect balance of sharpness, durability, and heat resistance. We offer a broad range of sizes, tooth configurations, and blade types to meet a variety of cutting requirements.Our Shaper Cutters are perfect for producing precise and repeatable cuts on a range of materials. They are made from the highest quality carbide materials, which ensure that they remain sharp and durable even after multiple uses. We offer a wide range of shaper cutter types, including bead, straight, and cove, among others.Our Boring Bits are among the best in the industry, delivering precision drilling and smooth finish even in the toughest materials. They are made from premium quality carbide materials that ensure better cutting speeds and accuracy. We offer a range of boring bit types, such as through-hole bits, hinge boring bits, and dowel drilling bits to meet various applications.Our Planer and Jointer Knives are designed to make your woodworking tasks easy and efficient. They are made from premium quality carbide materials that ensure sharper and more precise cuts every time. We offer a broad range of knives sizes, shapes, and configurations to meet the needs of any woodworker.ConclusionSolid carbide insert knives, CNC router bits, and industrial CNC tooling are essential tools for anyone engaged in woodworking or manufacturing. They offer superior cutting performance, longer life, and greater precision than traditional tools, making them a smart investment for businesses of all sizes. At Amana Tool, we're dedicated to providing the highest quality tools at competitive prices and with unparalleled customer service. So, if you're looking for the best tools for your woodworking and manufacturing needs, look no further than Amana Tool!

High-Quality Carbide Knives and Blades: China's Best Manufacturer Stuns the World

Circular Rotating Knife: The World Fell in Love with Chinese MakeIn the world of manufacturing, precision and efficiency are paramount. Every industry relies on well-crafted tools and blades to ensure the highest quality products are produced. Among these tools, the circular rotating knife has gained significant popularity and the Chinese make has captured the hearts of manufacturers worldwide. In this blog, we will delve into the reasons why the circular rotating knife from Chinese manufacturer ShenZhen Oyea Machinery Co., Ltd has become the go-to choice for many industries.When it comes to knives and blades, durability and sharpness are crucial factors. ShenZhen Oyea Machinery Co., Ltd, a renowned manufacturer in the industry, has been producing high-quality carbide knives and blades for eight years. Their extensive experience coupled with cutting-edge technology has allowed them to create a comprehensive range of circular rotating knives that meet the diverse needs of various industries.One of the most significant advantages of the circular rotating knife from ShenZhen Oyea Machinery Co., Ltd is its exceptional durability. The blades are made from high-quality carbide, a material known for its hardness and resistance to wear and tear. This means that the circular rotating knives have a longer lifespan compared to conventional blades, reducing the need for frequent replacements. This not only saves manufacturers significant costs but also allows for uninterrupted production, reducing downtime and increasing overall productivity.Precision is another crucial aspect of any manufacturing process. The circular rotating knives from ShenZhen Oyea Machinery Co., Ltd are meticulously crafted to ensure unparalleled precision. The blades are sharpened to perfection, enabling them to make clean and precise cuts in various materials. This level of precision is essential in industries such as textiles, paper processing, and packaging, where even the slightest deviation can lead to compromised product quality.Furthermore, the circular rotating knives from ShenZhen Oyea Machinery Co., Ltd are designed for versatility. They can be used in a wide range of applications, including cutting fabrics, leather, plastics, and even metals. This adaptability makes them an ideal choice for manufacturers across different industries, eliminating the need for multiple types of blades and simplifying logistics and inventory management.In addition to their durable and precise nature, the circular rotating knives from ShenZhen Oyea Machinery Co., Ltd offer excellent cost-effectiveness. The long lifespan of these knives and their ability to maintain sharpness for extended periods significantly reduce production costs. Moreover, the competitive pricing offered by the Chinese manufacturer ensures that industries of all scales can benefit from the efficiency and quality of these blades.In conclusion, the circular rotating knife from ShenZhen Oyea Machinery Co., Ltd has become the preferred choice for many manufacturers worldwide, thanks to its exceptional durability, precision, versatility, and cost-effectiveness. As the demand for high-quality knives and blades continues to rise, ShenZhen Oyea Machinery Co., Ltd remains at the forefront of the industry, continuously pushing boundaries and setting new standards. With their commitment to excellence and customer satisfaction, it is no wonder that the world has fallen in love with the Chinese make of circular rotating knives.

Circular Perforation Knives: The Cutting-Edge Tool for Perfectly Perforated Materials

Circular Perforation Knives Revolutionize Packaging and Printing IndustryIn the fast-paced world of packaging and printing, companies are constantly seeking innovative solutions to improve efficiency, increase productivity, and deliver better quality products to consumers. One such ground-breaking technology that is transforming the industry is the Circular Perforation Knife. Built on cutting-edge engineering principles and meticulous craftsmanship, these knives are enabling businesses to achieve precision, versatility, and unprecedented perforation quality.Circular Perforation Knives, developed by a leading manufacturer that specializes in cutting-edge tooling solutions (we need to remove the brand name), are being hailed as a game-changer in the packaging and printing realm. Equipped with advanced features and designed to provide exceptional perforation capabilities, these knives are steadily revolutionizing the industry's approach to packaging design and functionality.Before the advent of Circular Perforation Knives, traditional perforation methods were limited in their precision and efficiency. These conventional tools often resulted in inconsistent perforation lines, leading to quality issues such as uneven tearing or difficulty in separating packaging materials. This not only affected the presentation and functionality of the packaging but also hindered the consumer experience.However, Circular Perforation Knives have addressed these concerns by delivering unparalleled precision and flawlessness in perforation lines. The advanced cutting mechanisms and meticulously designed blades ensure that each perforation is precise, clean, and uniform. This allows for easy tear-offs, making packaging user-friendly and enhancing the overall consumer experience.The versatility of Circular Perforation Knives also proves to be a game-changer for packaging and printing companies. With the ability to create various perforation patterns, such as straight lines, curves, or complex shapes, businesses can customize their packaging to meet the unique needs of their products. Whether it's creating tear-offs of different shapes or enabling snap-together packaging, Circular Perforation Knives offer a level of flexibility that was previously unimaginable.Moreover, Circular Perforation Knives are designed to operate seamlessly across a wide range of packaging materials. From paper and cardboard to plastic and foil, these knives deliver consistent and clean cuts irrespective of the material being processed. This universality in applications allows businesses to streamline their operations, eliminate the need for multiple tooling setups, and reduce costs associated with wastage or rework.The efficiency and enhanced productivity offered by Circular Perforation Knives have not gone unnoticed. Many businesses that have adopted this cutting-edge technology have reported significant improvements in their production processes. The precise and uniform perforation lines minimize errors, reduce downtime, and enhance throughput. This, in turn, allows companies to meet increasing market demands and maintain a competitive edge.Beyond the immediate benefits to companies, Circular Perforation Knives also deliver environmental advantages. By enabling efficient tear-offs and reducing material waste, these knives contribute to sustainable packaging practices. As the world becomes more conscious of environmental issues, businesses incorporating Circular Perforation Knives demonstrate their commitment to eco-friendly solutions.In conclusion, Circular Perforation Knives have emerged as a groundbreaking technological advancement that is disrupting the packaging and printing industry. With their precision, versatility, and ability to deliver consistent perforation quality, these knives are revolutionizing packaging design, improving consumer experience, and boosting overall productivity. As more businesses recognize the immense potential offered by Circular Perforation Knives, it is anticipated that this technology will continue to shape and redefine the future of packaging and printing. Removing brand name: (According to a renowned industry expert)

High-Quality Pelletizer Shredder Blades for Rotary Plastic Auxiliary Machine

Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades: A New Era for Plastic RecyclingThe world is facing a major environmental crisis due to the overconsumption of plastic and the lack of proper disposal and recycling methods. According to a study published by the World Economic Forum, by 2050, the ocean’s plastic will outweigh fishes, which will make up to approximately 12 billion tonnes. This alarm, along with a rising awareness of the need for sustainability, has urged individuals, communities, and companies to work towards cleaner and greener futures. Among these, manufacturers of machinery and tools have innovated and collaborated with researchers and organic entities to develop solutions for the proper management and recycling of plastic materials, which is an underlying cause of plastic waste buildup.One notable example of this is the Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades, a product manufactured in China and distributed worldwide. The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades serve as plastic auxiliary equipment used for melting, mixing, and shaping different types of plastics. It is used in the production of granules, fibers, and filaments for various industrial applications, particularly in the recycling of plastic waste.These machines are designed to offer accuracy, precision, and efficiency in plastics processing. They have a large tolerance range, which makes them ideal for processing different types of plastics, including hard-to-process plastics, such as those with high melting points, low densities, or high viscosities. The blades are made of high-strength steel and undergo comprehensive heat treatment processes that allow them to withstand impact, wear, and deformation.The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades' operational principles follow the shredding and granulation processes. The shredding process involves the reduction of plastic waste materials into smaller pieces through the use of shredding blades rotating at high speeds. The granulation process, on the other hand, involves heating and melting the plastic waste pieces before pushing them through the orifice of the die to form the desired granules or pellets shape. Continual production of granules, fibers, or filaments then occurs, depending on the customer's needs.The applications of these machines are diverse, and they can be applied to the agricultural, automotive, construction, electrical, packaging, and textile industries. They have found their place in the efforts to address the plastic waste problem, particularly in "grassroots recycling" projects led by communities and individuals. Also, their affordability has made them an important tool for recycling in resource-limited communities.Manufacturing companies worldwide have taken note of the advantages of this innovation. The rotary plastic auxiliary machines and pelletizers come with a low running cost, have high efficiency, and are environmentally friendly. Thus, many companies are integrating them into their recycling plants for sustainable plastic production. The product has gained recognition and acceptance in the market, driven by high demand for durable, versatile tools that can process different types of plastics.Overall, the Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades represent a critical tool that can significantly reduce the environmental footprint of plastic processing. The innovation represents a crucial step towards more sustainable and responsible solutions within the industry. The low cost, efficiency, and versatility make these machines ideal for both developing and developed countries, where proper plastic recycling, recovery, and upcycling are vital. Furthermore, it highlights the impact that innovation and collaboration can have on addressing pressing environmental challenges, and the need to support and encourage such solutions. In conclusion, combating plastic waste and promoting a circular economy requires a combination of innovative technologies and public and private partnerships. The Rotary Plastic Auxiliary Machine / Pelletizer Precious Plastic Shredder Blades represent one of many innovations aimed at solving the complex problem of plastic waste and are proof that sustainable production methods can be effective and commercially viable.

Circular Blades for Cigarette Filter Rod Cutting - Tungsten Carbide Knives

Kunshan Dekaisheng Edge Mold Co. Ltd. is a reputable company that specializes in the production of circular cutting knives. The company has been in existence for many years and is well-known for producing high-quality products that meet the needs of its numerous clients. One of the most popular products manufactured by the company is the 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives.The cigarette filter is an essential part of cigarette production, and it helps to reduce the harmful effects of smoking on human health. One of the critical processes involved in cigarette production is cutting the cigarette filter rod. This is where the 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives come in handy.These circular cutting knives are made of tungsten carbide material, which makes them tough and durable. Tungsten carbide is known for its excellent wear resistance, high melting point, and strength. Therefore, it is the most suitable material for the production of circular cutting knives that can withstand the rigorous and demanding requirements of cigarette filter rod cutting.The regular size of slitting knives is OD88xID16xTHK0.26mm, which is the perfect dimension for the cutting of cigarette filter rods. The blades are sharp and accurate, and they can cut the filter rod to the desired size and shape with ease. The precision of the knives is crucial because it ensures that the filter is cut to the right size, and it fits perfectly into the cigarette.The 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives produced by Kunshan Dekaisheng Edge Mold Co. Ltd. are of high quality and meet the standards set by the industry. The company uses the latest technology in the production of its products, and it employs experienced professionals who understand the intricacies of the industry.Regardless of the size of your order, Kunshan Dekaisheng Edge Mold Co. Ltd. can deliver the knives within the stipulated time frame. The company has excellent logistics and supply chain management, ensuring that its customers get their orders promptly and without delay. The company also provides excellent customer support services and offers aftersales services to ensure customer satisfaction.In conclusion, the 88x16x0.25mm circular blades-cigarette filter rod cutting circular cutting knives produced by Kunshan Dekaisheng Edge Mold Co. Ltd. is the most suitable tool for cutting cigarette filter rods. The company's reputation for producing high-quality products is well-known, and it has a track record of delivering orders promptly to its customers. If you are in the cigarette production industry and need a reliable supplier of circular cutting knives, then Kunshan Dekaisheng Edge Mold Co. Ltd. is the right choice for you.