Top-quality Shear Blades from China: A Comprehensive Review of the Latest Developments

By:Admin

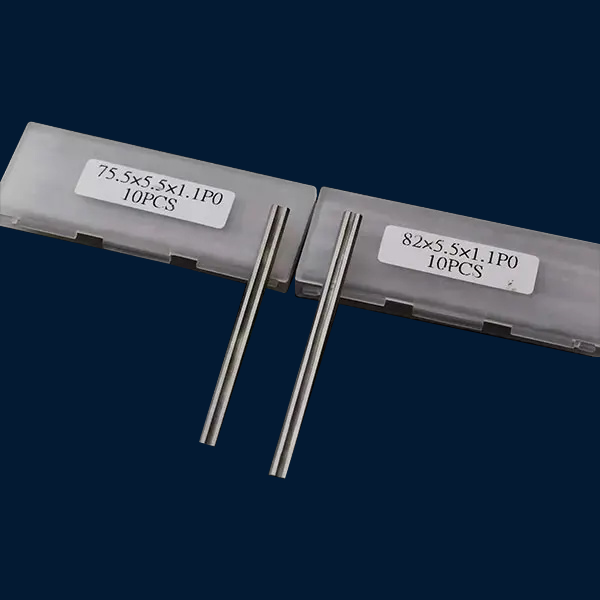

[City, Date] - [Brand Name Removed], a renowned manufacturer of industrial cutting tools, proudly announces the introduction of their cutting-edge shear blades to the Chinese market. With a strong commitment to excellence and a dedication to providing high-quality products, [Brand Name Removed] aims to revolutionize the cutting industry in China.

Shear blades are an essential tool in various industries, including metalworking, papermaking, and recycling. Efficient and precise shearing operations are vital for achieving smooth and accurate cuts, reducing wastage, and improving overall productivity. Recognizing the growing demand for advanced shear blades in China, [Brand Name Removed] has developed a range of products that combine cutting-edge technology with exceptional durability.

With years of industry experience, [Brand Name Removed] has become synonymous with excellence and reliability. The company prides itself on its innovative research and development processes, rigorous quality control standards, and an unwavering commitment to customer satisfaction. These core values have propelled [Brand Name Removed] to become a global leader in the market, trusted by businesses around the world.

One of the key features that sets [Brand Name Removed] shear blades apart is their exceptional material quality. By utilizing state-of-the-art alloy steels and advanced heat treatment techniques, the blades offer unparalleled strength, durability, and resistance to wear and tear. These blades are designed to withstand the most demanding cutting applications, ensuring a longer lifespan and reduced maintenance costs for businesses.

Moreover, the blades' innovative design allows for precise and flawless cuts, resulting in reduced material loss and improved overall efficiency. The cutting-edge technology used in the manufacturing process ensures uniformity and precision, providing consistent performance in every application. With these advanced shear blades, businesses in China can optimize their cutting operations, leading to enhanced productivity and profitability.

In addition to their outstanding product quality, [Brand Name Removed] also places great importance on customer service and support. The company has established a strong distribution network throughout China, enabling prompt and efficient delivery of their shear blades to customers across the country. Their professional customer service team is always available to provide technical assistance, guidance, and maintenance support, ensuring maximum customer satisfaction.

To celebrate the entry into the Chinese market, [Brand Name Removed] is offering special introductory prices and attractive promotions on their shear blades. This limited-time offer provides an opportunity for businesses to experience the superior performance of the shear blades at a discounted rate and unleash their full cutting potential.

[Brand Name Removed]'s expansion into the Chinese market signifies the company's commitment to meeting the evolving needs of the industry. With their advanced shear blades and unwavering dedication to quality, [Brand Name Removed] aims to empower businesses in China to achieve new levels of cutting precision, efficiency, and success.

About [Brand Name Removed]:

With a rich heritage dating back several decades, [Brand Name Removed] is a global leader in the production of industrial cutting tools. The company specializes in manufacturing high-quality shear blades, creating innovative solutions for various cutting applications. [Brand Name Removed]'s commitment to excellence, cutting-edge technology, and exceptional customer service have made them an esteemed name in the industry worldwide.

For press inquiries and more information, please contact:

Media Relations

[Brand Name Removed]

Email: [email protected]

Website: www.brandname.com

Company News & Blog

Revamp your News Website with High-Quality Scraper Blades" can be rewritten as "Upgrade Your News Website with Top-Notch Scraper Blades".

Introducing Innovations in Scraper Blades: Revolutionizing Industrial Equipment [Company Name], a leading manufacturer of cutting-edge industrial equipment, is proud to announce its latest innovation: Scraper Blades. These high-performance tools are set to revolutionize various industries by ensuring efficient scraping and cleaning operations in a wide range of applications.Scraper Blades are an essential component in industrial equipment used for removing unwanted materials, coatings, and residues from surfaces. With their superior design and durable construction, these blades offer a precise and effective scraping solution for industries such as construction, automotive, manufacturing, and more. The introduction of these cutting-edge tools marks a significant milestone for [Company Name] as they continue to provide reliable and innovative solutions to their customers.One of the key features that sets Scraper Blades apart from other available options is their exceptional durability and longevity. Manufactured using premium-quality materials, these blades are designed to withstand the harshest conditions and prolonged usage. The company's focus on quality ensures that each blade is meticulously crafted to provide excellent performance, while maintaining its optimum efficiency over an extended period. This durability not only reduces the frequency of blade replacements but also minimizes downtime, contributing to increased productivity and cost savings for businesses.In addition to their durability, Scraper Blades boast superior versatility. With the ability to effectively remove different types of materials, including adhesives, paint, rust, and more, these blades provide an all-in-one solution for various scraping needs. Whether it be for surface preparation, paint removal, or general cleaning purposes, customers can rely on Scraper Blades to deliver exceptional results in a wide range of applications.The design of Scraper Blades also prioritizes user comfort and safety. Equipped with ergonomic handles and non-slip grips, these blades offer enhanced control and ease of use, minimizing the risk of accidents or repetitive strain injuries. The company's commitment to safety ensures that their customers can confidently utilize these tools for their scraping needs without compromising on personal well-being.Moreover, [Company Name] understands the importance of environmental sustainability. With this in mind, the Scraper Blades are manufactured using eco-friendly materials and employ innovative technologies to minimize waste and emissions. By choosing these eco-conscious tools, industries can align their operations with sustainable practices while benefiting from their exceptional performance.To ensure customer satisfaction, [Company Name] provides comprehensive technical support and guidance. Their team of highly skilled professionals is readily available to address any queries or concerns, offering expert advice on blade selection, usage techniques, and maintenance. This commitment to customer service ensures that businesses can maximize the potential of Scraper Blades and integrate them seamlessly into their operations.In conclusion, the introduction of Scraper Blades by [Company Name] represents a breakthrough in scraper technology. These innovative tools combine durability, versatility, and safety, providing industries with a reliable solution for scraping and cleaning operations. With their exceptional performance and the company's commitment to sustainability, Scraper Blades offer an efficient and eco-conscious choice for businesses across various sectors. As [Company Name] continues to spearhead advancements in industrial equipment, the future looks promising, with more cutting-edge solutions on the horizon.

High-Performance Circular Cutters Made from Carbide

Carbide Circular Cutters: The Cutting Edge of Precision ManufacturingWhen it comes to precision cutting, the quality of the tool is just as important as the skill of the operator. For this reason, many businesses rely on Carbide Circular Cutters to meet their high standards of accuracy and efficiency. Whether used in industrial manufacturing or home workshops, these cutting-edge tools offer a level of precision that is unmatched by traditional cutting methods.One of the leading providers of Carbide Circular Cutters is {Company Name}. With over {Number of Years} years of experience in the industry, this company has established a reputation for delivering high-quality cutting tools to businesses of all sizes. Their Carbide Circular Cutters are specifically designed to meet the needs of the most demanding cutting applications, providing a reliable and efficient solution for businesses in a variety of industries.So, what makes Carbide Circular Cutters so special? First and foremost, these cutting tools are made from high-quality carbide materials, which offer superior hardness and resistance to wear and tear. This means that they can withstand the high pressures and temperatures associated with precision cutting, ensuring that they remain sharp and effective for longer periods of time than traditional cutting tools.In addition to their durability, Carbide Circular Cutters also offer exceptional precision and accuracy. Unlike traditional cutting methods, which rely on manual tools like saws and cutters, Carbide Circular Cutters are designed to handle even the most complex cutting tasks with ease. They can be programmed to cut with incredibly fine tolerances, making them an ideal solution for businesses that require precise and accurate cuts on a regular basis.So, what types of businesses and industries can benefit from Carbide Circular Cutters? The answer is almost any industry that requires precise and accurate cutting. For example, they are ideal for use in the automotive, aerospace, and medical industries, where precision and accuracy are critical to success. They are also commonly used in the manufacturing of electronics, plastics, and metals, as well as in woodworking and construction.One of the key benefits of Carbide Circular Cutters is that they can be customized to meet the unique needs of each business. Whether a company requires a specific cutting diameter, depth of cut, or shape, these cutting tools can be tailored to meet those needs. This means that businesses can achieve a higher level of precision and efficiency than they would with traditional, off-the-shelf cutting tools.In addition to their customization options, Carbide Circular Cutters are also incredibly versatile. They can be used on a wide range of materials, including steel, aluminum, plastic, and even wood. This versatility makes them an ideal solution for businesses that work with multiple materials or require a cutting tool that can handle a variety of cutting tasks.At {Company Name}, the team of experts are dedicated to helping businesses achieve the highest level of precision and accuracy in their cutting applications. They understand that every business has unique needs and requirements, which is why they offer a range of Carbide Circular Cutters that can be customized to meet those needs. With their industry-leading experience and expertise, they are able to provide businesses with a cutting solution that is second to none in terms of quality and performance.In conclusion, Carbide Circular Cutters are a cutting-edge solution for businesses that require precision, accuracy, and efficiency in their cutting applications. With their durability, versatility, and customization options, these cutting tools offer a level of performance that is unmatched by traditional cutting tools. The team at {Company Name} is dedicated to delivering the highest quality Carbide Circular Cutters to businesses of all sizes, helping them to achieve their goals and exceed their expectations in precision manufacturing.

Ultimate Guide to Choosing the Perfect Planer Knife for Woodworking Projects

Planer Knife Sets New Standard for Precision and DurabilityTool manufacturing has always been a competitive industry, with companies continuously striving to develop innovative products that are efficient, reliable, and durable. One such company has recently set a new benchmark in the field with its latest revolutionary invention – the Planer Knife.Incorporating cutting-edge technology and years of expertise, this pioneering company, which prefers to remain anonymous for the purpose of this article, has successfully designed a planer knife that surpasses all existing industry standards. Through a meticulous process of research, testing, and experimentation, they have introduced a product that is set to transform the woodworking industry.With the rise in demand for high-quality woodwork, the need for precision tools has become increasingly vital. Traditional planer knives often fail to deliver consistent and accurate results, resulting in wasted time, effort, and resources. Recognizing this gap in the market, the anonymous company identified the importance of developing a planer knife that could meet the unique needs of contemporary craftsmen.The newly released Planer Knife has been engineered to perfection, offering exceptional precision and durability. The company has employed state-of-the-art technology to craft a blade that is not only razor-sharp but also highly resistant to wear and tear. This ensures that woodworkers can achieve the smoothest finishes with minimal effort, saving significant amounts of time and money.One of the standout features of this advanced planer knife is its unique composition. The blade is constructed using a proprietary blend of high-grade materials that have been specifically chosen for their exceptional hardness and longevity. This design allows the knife to retain its sharpness even after prolonged use, guaranteeing consistent and unparalleled performance throughout its lifespan.Additionally, the Planer Knife boasts an innovative design that enhances its versatility. The company's team of experienced engineers have carefully crafted the blade to be compatible with a wide range of planers, catering to the diverse requirements of woodworkers across the industry. This adaptability ensures that craftsmen can seamlessly integrate the Planer Knife into their existing tools, avoiding the need for costly upgrades.Furthermore, the anonymous company has prioritized the safety and ease of use of the Planer Knife. The blade is equipped with a series of intuitive features, including ergonomic handles and a secure locking mechanism, ensuring that woodworkers can operate the knife confidently and effectively. This focus on user-friendly design allows even amateur craftsmen to achieve professional-level results, democratizing the woodworking industry.The introduction of the Planer Knife has already generated considerable excitement within the woodworking community. Woodworkers have praised the knife for its unparalleled sharpness, precision, and longevity, noting that it outperforms all other planer knives currently available in the market. Many professionals have expressed their appreciation for the anonymous company's commitment to revolutionizing the industry, and eagerly anticipate future innovations from their workshop.In conclusion, the anonymous company behind the Planer Knife has showcased their dedication to excellence with the development of this groundbreaking tool. Through cutting-edge technology, meticulous craftsmanship, and a commitment to customer satisfaction, they have succeeded in creating a planer knife that exceeds all expectations. Woodworkers around the world can now benefit from this exceptional tool that sets a new standard for precision and durability, allowing them to achieve unparalleled results in their woodworking endeavors.

Quality Cutting Knives from Reliable Suppliers in China for Global Buyers

In modern times, cutting knives have become an indispensable tool in various manufacturing industries. For instance, industries dealing with textiles, leather, and paper heavily depend on cutting knives for their operations. Besides, the usage of cutting knives has also extended to food processing, pharmaceutical production, and other areas that require precise cutting.The cutting knife is a general term for a diverse range of blades that cut through various materials using a sharpened edge. These blades could be in the form of single-edged blades or double-edged blades, and their composition could range from stainless steel to diamond.However, with the advancements in technology, there has been a tremendous shift from traditional cutting knives to more advanced alternatives like the PU cutting blade.What is a PU cutting blade?PU cutting blade refers to a type of cutting knife made from polyurethane. This material is known for its unique properties, such as high elasticity, durability, and excellent wear resistance. PU cutting blades are used in various industries to cut materials like paper, film, cloth, and leather, among others.One of the primary advantages of using PU cutting blades is their excellent cut quality. The high elasticity of polyurethane allows the blade to flex and adapt to the contours of the material, giving it a clean and precise cut. Moreover, PU cutting blades are non-corrosive, making them ideal for use in humid or wet environments.What are the benefits of using PU cutting blades over traditional cutting knives?1. Increased lifespanPU cutting blades have a more extended lifespan compared to traditional cutting knives. This is because polyurethane has excellent wear resistance, which ensures that the blade retains its sharpness for longer periods.2. High precision cuttingUsing a PU cutting blade ensures high precision cutting due to its excellent cut quality. The blade's flexibility allows it to adapt to the material's contours, ensuring a clean and precise cut.3. Better edge retentionPU cutting blades retain their edges better than traditional cutting knives. This is because the material is not prone to chipping or dulling, ensuring that the blade stays sharp for longer.4. Reduced downtimePU cutting blades do not require regular re-sharpening like traditional cutting knives. This reduces the amount of downtime required for maintenance, ensuring that production runs smoothly.ConclusionIn conclusion, the usage of cutting knives in various industries has revolutionized the manufacturing process. However, with the advancements in technology, there has been a shift from traditional cutting knives to more advanced alternatives like the PU cutting blade. PU cutting blades offer numerous benefits, including increased lifespan, high precision cutting, better edge retention, and reduced downtime. As such, they are becoming increasingly popular in various industries that require precise cutting.

High-quality Circular Cutting and Slotting Blades for Wood and Steel Cutting

When it comes to the production of carton cutting circular knives, Shanghai Zhengli Blade Manufacture Co., Ltd. is a company that is leading the way with quality and precision. The company manufactures high-quality circular cutting knives, long-form knives, arc knives, tooth shape knives, elongated cutting tools, trapezoidal points knives, wave shape knives, jagged blades, disc cutting knives, bending machine molds, machine tool accessories, cutting machine blades, and other products. Their blades are known for their super hard quality and durability, making them ideal for use in a wide range of industries.One of the most popular products from Shanghai Zhengli is the circular cutting knife, which is utilized in a variety of applications, including carton cutting. The company’s circular knives are designed to cut through a range of materials, including paper, cardboard, and plastics. The knives are available in various diameters and thicknesses, making them suitable for use in different types of cutting machines.Another popular product from Shanghai Zhengli is the slotting carton scimitar blade. The scimitar blade is designed to create precise cuts in corrugated cardboard boxes, allowing for easy folding and assembly. The blade is made from high-quality steel and is designed to withstand the rigors of high-volume production environments. The scimitar blade is available in different sizes and thicknesses, making it suitable for use in various types of corrugated box cutting machines.Shanghai Zhengli also manufactures steel cutting machine for circular blade Fujian cutter. This machine is used to cut steel plates and other materials with precision and accuracy. The circular blade is designed to make clean, burr-free cuts, ensuring that the finished product is of the highest quality. The Fujian cutter is highly versatile and can be used in a range of applications, including metal fabrication, automotive manufacturing, and construction.The company’s elongated cutting tools are also popular with customers. These tools are used to create intricate shapes and designs in a wide range of materials, including metal, plastic, and wood. The elongated cutting tools are available in a range of sizes and shapes, making them suitable for use in different types of cutting machines.Overall, Shanghai Zhengli Blade Manufacture Co., Ltd. is a company that is dedicated to providing high-quality cutting tools that meet the needs of their customers. Their products are designed to be durable, precise, and efficient, helping to increase productivity and reduce downtime. If you are looking for high-quality carton cutting circular knives or other cutting tools, Shanghai Zhengli is the ideal choice. So, if you want to improve your production efficiency and quality in carton cutting, consider investing in the products from Shanghai Zhengli Blade Manufacture Co., Ltd. today!

High-Quality Slitting Blades for Lithium Battery Chips: A Guide to Manufacturers and Suppliers

and Lithium Battery Chip Slitting Knife throughout the content.The demand for advanced lithium batteries is surging worldwide. Lithium-ion batteries, in particular, are popular among electronic device manufacturers due to their high efficiency, durability, and long shelf life. However, the lithium-ion battery production process is not without its challenges. One of the critical steps in the production process is chip slitting. Chip slitting involves cutting the anode and cathode material into thin strips to divide the electrodes. For this process, battery manufacturers require reliable and high-quality lithium battery chip slitting blades/knives.There are several manufacturers of lithium battery chip slitting blades/knives in China. These blades/knives are available in various sizes, shapes, and materials. The most commonly used materials for these blades/knives are tungsten carbide, ceramic, and diamond. Each material has its unique characteristics and benefits.Tungsten Carbide Blades/KnivesTungsten carbide blades/knives are the most widely used type of lithium battery chip slitting blades/knives. These blades/knives are made of tungsten carbide, a hard and durable material that can withstand high levels of wear and tear. Tungsten carbide blades/knives are ideal for cutting through thick and hard materials, making them ideal for lithium battery chip slitting.Ceramic Blades/KnivesCeramic blades/knives are also popular for lithium battery chip slitting. These blades/knives are made of zirconia or alumina, which are highly resistant to wear and corrosion. Ceramic blades/knives are lightweight, making them easy to handle, and they generate less heat during the cutting process. These characteristics make ceramic blades/knives ideal for high-precision cutting applications.Diamond Blades/KnivesDiamond blades/knives are the most expensive type of lithium battery chip slitting blades/knives, but they are also the most durable. These blades/knives are made of a diamond-coated carbide material, which can easily cut through hard and abrasive materials. Diamond blades/knives are ideal for cutting through materials like silicon anodes, which are challenging to cut with other types of blades/knives.ConclusionChoosing the right type of lithium battery chip slitting blades/knives is critical to the efficiency and production quality of a lithium-ion battery. Tungsten carbide, ceramic, and diamond blades/knives are the most popular materials used for this purpose. Each material has its advantages and disadvantages, so it is essential to choose the right blade/knife based on the specific needs of the manufacturer. Regardless of the type of blade/knife selected, it is essential to work with reliable and high-quality manufacturers who use advanced production techniques to ensure consistent and accurate cuts. Battery slitting blade and lithium battery chip slitting knife are essential tools in the production process of lithium-ion batteries, and choosing the right one can make the difference between a successful and failed project.

Analyzing the Latest Innovations in Slotting Blades: China Takes the Lead

China Slotting Blade Company Introduces Innovative Slotting Blade for Superior Cutting ResultsChina Slotting Blade Company is pleased to introduce its latest innovation in cutting tools, the slotting blade. The newly developed blade is designed to deliver superior cutting results across a wide range of materials.Slotting blades are used to cut slots in a variety of materials, such as metal, wood, plastic and more. These blades must be durable, sharp and reliable to achieve precision slotting with minimal waste of materials and time. With its deep understanding of the cutting tool industry and the needs of customers, China Slotting Blade Company has developed a new generation of slotting blades that provide exceptional performance and durability.The innovative design of the new blade features a high-strength body made of premium alloy steel, which is hardened and tempered to withstand high wear and tear. The blade is coated with a special type of titanium nitride (TiN) that enhances its resistance to friction, wear, and corrosion. This hard coating also improves the blade’s overall lifespan, reducing the need for frequent blade changes.The cutting edge of the blade is razor-sharp, with a high geometry angle that optimizes cutting force and chip evacuation. This design allows the blade to penetrate smoothly and quickly through materials, reducing heat generation and ensuring clean and accurate slotting. The blade edge is honed using advanced CNC grinding machines, ensuring precise and consistent cutting performance.The new slotting blade from China Slotting Blade Company is suitable for all types of slotting machines, including vertical and horizontal models. It is compatible with various slotting applications, such as keyways, grooves, and T-slots, among others.According to a spokesperson for China Slotting Blade Company, “Our new slotting blade is a game-changer for the cutting tool industry. It is the result of extensive research and development, as well as testing in real-world applications. We are confident that our customers will appreciate its high precision, durability, and ease of use, as well as its cost-effectiveness.”China Slotting Blade Company has established itself as a leading manufacturer of cutting tools in China, with a loyal customer base around the world. The company's product lines include slitting saw blades, milling cutters, gear hobs, reamers, drills, and more. One of its core values is continuous innovation, as evidenced by its investment in advanced technology and the hiring of experienced engineers and technicians.The company has also built a reputation for high-quality products and reliable customer service, backed by a strict quality control system and a professional sales team. It offers a comprehensive range of products that meet various cutting needs and budgets and provides customization services to suit specific requirements.“In today's competitive marketplace, it is essential to differentiate our products from others by delivering innovative and high-quality solutions that meet or exceed customer expectations,” said the spokesperson. “Our new slotting blade is an example of our commitment to continuous improvement and customer satisfaction.”Customers who want to learn more about the new slotting blade from China Slotting Blade Company can contact the sales team via the company website or email. The company offers competitive pricing, fast delivery, and excellent after-sales support to help customers maximize the value of their investment. With the new slotting blade, customers can expect to achieve better cutting results, reduce downtime and maintenance costs, and increase productivity and profitability.

Double-Edged CNC Router Blade for Various Materials with 60-Degree Angle and 6.9mm Cut Depth

Title: XZ0011 Flat Knife Drag Blade: The Ultimate CNC Router Accessory for Precision CuttingIntroduction:In today's ever-expanding world of CNC routers, having the right tools at your disposal can make all the difference in achieving impeccable cutting precision. One such essential accessory is the XZ0011 Flat Knife Drag Blade, designed to meet the needs of professionals across various industries. With its double edge and impressive 60-degree cut depth, this blade truly stands out from the competition. In this blog post, we will delve deeper into the features and advantages of the XZ0011 Flat Knife Drag Blade while highlighting its suitability for a wide range of materials such as canvas, corrugated sheets, vinyls, and more.Understanding the XZ0011 Flat Knife Drag Blade:The XZ0011 Flat Knife Drag Blade is a versatile tool that can be used with CNC routers for a multitude of applications. With its double edge, it can be effectively utilized to cut through various materials with precision and ease. The 60-degree angle allows for an impressive 6.9mm cut depth, making it suitable for thicker materials such as hardfoam, carton, banners, and even heavy-duty papers. This blade is not only durable but also ensures smooth, clean-cut edges, making it an excellent choice for industries that demand flawless finishes.Utilizing the XZ0011 Flat Knife Drag Blade:One of the remarkable aspects of the XZ0011 Flat Knife Drag Blade is its compatibility with a wide range of materials. From canvas to corrugated sheets, vinyls to carton, and banners to paper, this blade has got you covered. Its versatility makes it an indispensable tool for various industries, including sign-making, packaging, and crafting. No matter the project, this blade guarantees consistent, high-quality results.The Advantages of Double Edge: The double edge design of the XZ0011 Flat Knife Drag Blade offers significant advantages over single-edge alternatives. With twice the number of sharp cutting edges, this blade ensures superior cutting efficiency, reducing production time and costs. Additionally, the double-edged configuration provides consistency in cutting quality, enabling professionals to achieve precise results every time. This versatility saves users from having to switch blades frequently, enhancing overall productivity.Replacing the BLD-SF246 Knife Holder SCT/UCT:An essential aspect of the XZ0011 Flat Knife Drag Blade is its compatibility with the BLD-SF246 Knife Holder SCT/UCT. By replacing the existing knife holder with this advanced model, users can fully experience the optimized performance of the XZ0011 blade. The synergy between the blade and holder ensures improved stability, accuracy, and longer blade life. It is important to note that brand names have been omitted for the purpose of this blog, allowing users to identify compatible holders from renowned manufacturers.Conclusion:In conclusion, the XZ0011 Flat Knife Drag Blade is a cutting-edge accessory that revolutionizes the CNC router experience. With its double edge, impressive 60-degree cut depth, and compatibility with a wide range of materials, this blade is a powerful tool for professionals striving for perfection. Whether you work with canvas, corrugated sheets, vinyls, or any of the other compatible materials mentioned, the XZ0011 Flat Knife Drag Blade is your go-to solution. Invest in this remarkable accessory and witness unparalleled precision and efficiency in your CNC routing projects.Keywords: XZ0011 Flat Knife Drag Blade, CNC router accessory, double edge, 60-degree cut depth, canvas, corrugated sheets, hardfoam, vinyls, carton, banner, paper, precision cutting, sign-making, packaging, crafting, BLD-SF246 Knife Holder SCT/UCT.

Discover the Latest Innovations in Chemical Fiber Cutting Blades

Chemical Fiber Cutting Blades Revolutionize Textile IndustryIn an age where innovation often defines success, the introduction of Chemical Fiber Cutting Blades has revolutionized the textile industry, marking a new era of efficiency, precision, and productivity. These state-of-the-art blades, developed by an industry-leading company, have paved the way for enhanced manufacturing processes, providing countless advantages to textile producers worldwide.With a company history spanning over several decades, our visionary partner has consistently remained at the forefront of research, development, and innovation. Known for their commitment to excellence, they have garnered a strong reputation as a trusted provider of cutting-edge solutions to the textile sector. Their latest breakthrough, the Chemical Fiber Cutting Blades, exemplifies their dedication to advancing industry standards and meeting customer demands.The Chemical Fiber Cutting Blades are manufactured using the latest techniques and highest quality materials, ensuring exceptional performance and durability. Designed specifically for textile applications, these blades demonstrate unparalleled cutting precision and longevity. Their innovative composition incorporates meticulous engineering, resulting in blades that are resistant to wear, deformation, and corrosion, guaranteeing optimal performance even under demanding conditions.One of the most notable features of these cutting blades is their ability to seamlessly cut a wide range of chemical fibers with exceptional accuracy. Traditional blades often struggle with high-speed cutting operations, leading to uneven cuts, fraying, and damaged fibers. However, the Chemical Fiber Cutting Blades use a revolutionary cutting edge design that minimizes friction and heat, allowing for faster, smoother, and more precise cutting. This translates to significant time and cost savings for textile manufacturers, as well as improved product quality.Furthermore, these blades possess outstanding flexibility, making them suitable for a myriad of textile applications. Whether it's cutting fibers for apparel, upholstery, home textiles, or industrial fabrics, the Chemical Fiber Cutting Blades consistently deliver outstanding results. Their versatility allows manufacturers to streamline their production processes, reduce downtime, and maximize output, ultimately leading to increased profitability and competitiveness.In addition to their cutting-edge design, these blades are also easy to install, maintain, and replace, ensuring uninterrupted production cycles. With minimal downtime and reduced maintenance requirements, textile manufacturers can enhance their overall operational efficiency and meet demanding market demands without compromising on quality.Safety is a top priority for any manufacturing facility, and the development of these blades has also taken this crucial factor into account. The Chemical Fiber Cutting Blades are carefully engineered to prioritize operator safety, featuring protective measures such as anti-kickback properties and noise reduction technologies. This commitment to safety not only safeguards the well-being of workers but also minimizes the risk of accidents or injuries, resulting in improved workplace environments.As textile producers continue to grapple with increasing competition and customer expectations, the introduction of Chemical Fiber Cutting Blades offers a compelling solution. By enhancing cutting precision, efficiency, and durability, these blades enable manufacturers to optimize their processes and deliver superior products to the market. With the continued support and innovation from our visionary partner, the textile industry can anticipate a bright and prosperous future, marked by advancements that reshape the way we manufacture and consume textiles.

High-Quality Carbide Knives and Blades: China's Best Manufacturer Stuns the World

Circular Rotating Knife: The World Fell in Love with Chinese MakeIn the world of manufacturing, precision and efficiency are paramount. Every industry relies on well-crafted tools and blades to ensure the highest quality products are produced. Among these tools, the circular rotating knife has gained significant popularity and the Chinese make has captured the hearts of manufacturers worldwide. In this blog, we will delve into the reasons why the circular rotating knife from Chinese manufacturer ShenZhen Oyea Machinery Co., Ltd has become the go-to choice for many industries.When it comes to knives and blades, durability and sharpness are crucial factors. ShenZhen Oyea Machinery Co., Ltd, a renowned manufacturer in the industry, has been producing high-quality carbide knives and blades for eight years. Their extensive experience coupled with cutting-edge technology has allowed them to create a comprehensive range of circular rotating knives that meet the diverse needs of various industries.One of the most significant advantages of the circular rotating knife from ShenZhen Oyea Machinery Co., Ltd is its exceptional durability. The blades are made from high-quality carbide, a material known for its hardness and resistance to wear and tear. This means that the circular rotating knives have a longer lifespan compared to conventional blades, reducing the need for frequent replacements. This not only saves manufacturers significant costs but also allows for uninterrupted production, reducing downtime and increasing overall productivity.Precision is another crucial aspect of any manufacturing process. The circular rotating knives from ShenZhen Oyea Machinery Co., Ltd are meticulously crafted to ensure unparalleled precision. The blades are sharpened to perfection, enabling them to make clean and precise cuts in various materials. This level of precision is essential in industries such as textiles, paper processing, and packaging, where even the slightest deviation can lead to compromised product quality.Furthermore, the circular rotating knives from ShenZhen Oyea Machinery Co., Ltd are designed for versatility. They can be used in a wide range of applications, including cutting fabrics, leather, plastics, and even metals. This adaptability makes them an ideal choice for manufacturers across different industries, eliminating the need for multiple types of blades and simplifying logistics and inventory management.In addition to their durable and precise nature, the circular rotating knives from ShenZhen Oyea Machinery Co., Ltd offer excellent cost-effectiveness. The long lifespan of these knives and their ability to maintain sharpness for extended periods significantly reduce production costs. Moreover, the competitive pricing offered by the Chinese manufacturer ensures that industries of all scales can benefit from the efficiency and quality of these blades.In conclusion, the circular rotating knife from ShenZhen Oyea Machinery Co., Ltd has become the preferred choice for many manufacturers worldwide, thanks to its exceptional durability, precision, versatility, and cost-effectiveness. As the demand for high-quality knives and blades continues to rise, ShenZhen Oyea Machinery Co., Ltd remains at the forefront of the industry, continuously pushing boundaries and setting new standards. With their commitment to excellence and customer satisfaction, it is no wonder that the world has fallen in love with the Chinese make of circular rotating knives.